Double toothed roll crusher is essential equipment in small stone factories and it is a commonly used type of roller crusher. Because of its simple structure, easy maintenance, and low price, it is popular to aggregate and coal ore suppliers.

FTM Machinery Double Roller Crusher Price: From $3, 500 / Set Get the Latest Price

Materials crushed by double roll crusher

Double toothed roll crusher is suitable for crushing various types of ores, used as secondary or tertiary crushing machinery. It is widely used in construction, metallurgy, building materials, water conservancy, electricity, refractory, and other industrial sectors.

1. Crushing various rocks

Double toothed roller crusher is generally used for crushing medium-hard rocks with compressive strength of less than 200 Mpa, such as limestone, phosphate, basalt, granite, river pebbles, iron ore, gold ore, copper ore, lead-zinc ore, nickel ore, asphalt, bricks, cement, and other materials.

2. The first choice for crushing coal

Double toothed roller crusher is a new type of equipment recommended by major coal plants for crushing raw coal, coke, lignite, and activated carbon. It crushes the coal by squeezing the double toothed rollers and easily removes the materials adhering to the rollers.

The roller crusher has dual functions of pre-screening and crushing. Small and medium-sized materials in the coal mine are directly leaked from the gap between the toothed rollers to avoid reprocessing. The phenomenon of over-crushing is improved.

3. Crushing sticky materials

The toothed roller crusher is very useful for crushing clay, cohesive materials, or rocks mixed with soil with water content up to 30%, such as kaolin, bentonite, montmorillonite, etc.

Because equipped with a scraper and adjustable discharge size, it can keep the groove and working surface clean. For wet and viscous materials, it can easily complete the crushing operation without sticking or clogging.

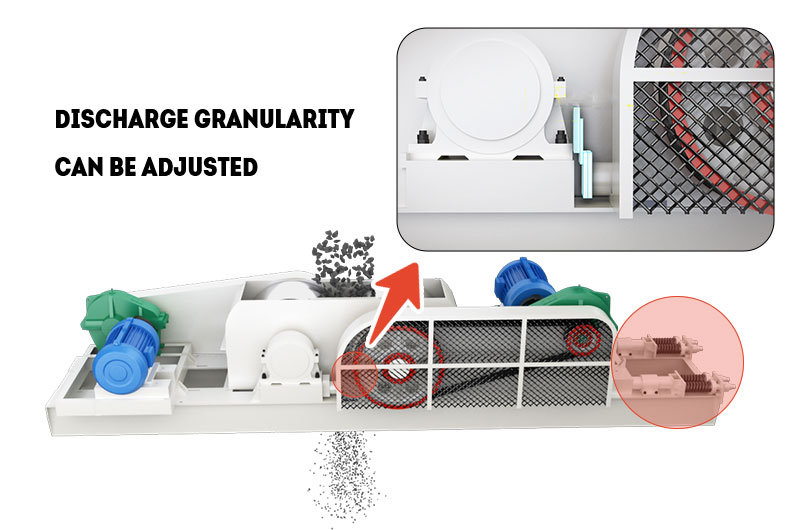

Discharge granularity can be adjusted

The double roller crusher is equipped with a discharge regulating device. The crushing gear is operated by a hydraulic system, which is used to adjust the space between tooth rollers, more convenient and fast operation.

According to the actual production requirements, the users can adjust the size of the discharge by adjusting the top bolt of the wedge-shaped device. The particle size of the crushed product can reach 2–10 mm, to meet the need of different users.

How does the teethed roll crusher work?

A double toothed roll crusher with less volume is composed of two toothed rollers, which are installed in parallel and rotated in opposite directions.

The two-toothed rollers adopt non-meshing and non-constant speed operation to strengthen the degree of occlusion, which ideally prevents the material from slipping thus improving the crushing efficiency.

Generally speaking, materials are crushed in three stages in a double toothed roller crusher.

- The material enters the crushing chamber by the impact force of the deep tooth gear for the first crushing.

- The large-block material is cut by the teeth to complete the second crushing.

- Then squeezed when they enter the toothed rollers to complete the third crushing.

- Finally, the crushed material is discharged from the outlet with the rotation of the toothed roller.

Why is the roll crusher suitable for open pit crushing?

Toothed roll crusher has good applicability and plays an important role in open-pit mining, especially in open-pit coal production. Four reasons for open-pit ore crushing:

1. Strong meshing capacity

The teeth of the crusher are composed of large and small teeth at intervals, which can effectively improve the meshing ability of the toothed rollers while ensuring the ideal particle size. Strong meshing capacity can improve the equipment processing capacity, reduce the tooth roller wear, and prolong the tooth plate service life.

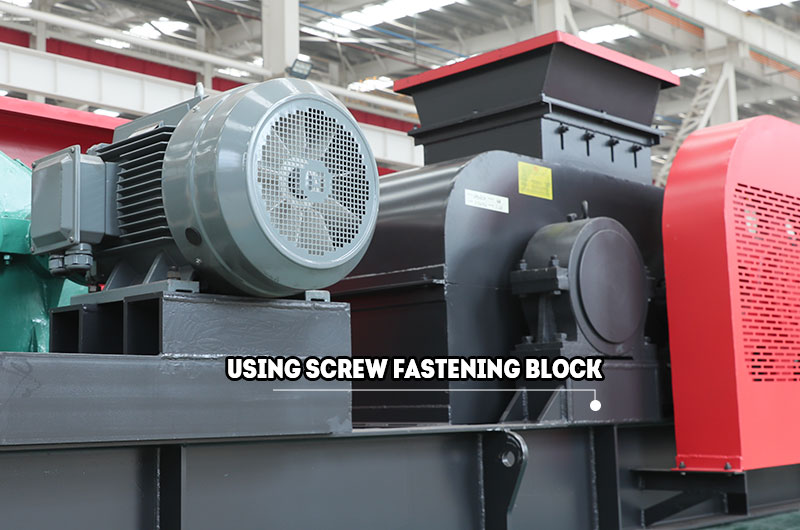

2. Easy replacement of parts

The connection between the tooth plate and tooth roller seat adopts a screw fastening block. It not only guarantees connection strength, but also has good interchangeability and replaceability.

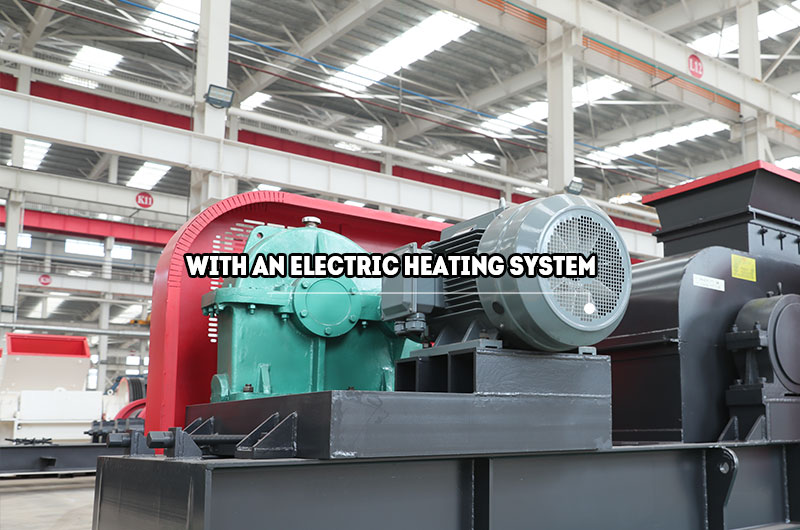

3. Tooth material can withstand low temperature

The motor is equipped with an electric heating system, and the hydraulic coupling and reducer use low-temperature synthetic oil, which ensures the transmission system's smooth operation even at a low temperature of -30°C.

4. High wear resistance

The tooth plate adopts medium carbon bainite wear-resistant cast steel. The wear resistance of this material is about 40% higher than that of the surfacing wear-resistant layer of 40Cr steel. In addition, the entire tooth roller structure, including the toothed plate, toothed roller seat, and threaded fastening block makes the strength and hardness of each component more balanced and reasonable.

Double toothed roll crusher for sale in Russia

The Russian customer's coal mine adopts the single-bucket truck and semi-continuous mining process. Raw coal has a large particle size and gangue has a high hardness. In the original production line, he first crushed the material to less than 300 mm, then crushed them to less than 70 mm with a ring hammer crusher. The crushed material of 70 mm was transported to the coal storage bunker for screening to final products of 25–70 mm.

Double roll crusher for coal crushing in Russia

The customer's original ring hammer crusher after long-term use has the following problems:

- The product over-crushing rate is high, which seriously affects the economic benefits of the enterprise;

- The spindles, hammers, and strainers are badly worn and often need to be replaced;

- High equipment failure rate, and high maintenance cost.

To reduce the operating cost and labor intensity of workers and ensure the normal operation of the production system, technical improvements are urgently needed. Finally, the user chose FTM Machinery toothed roll crusher to replace the original crusher.

After the double toothed roller crusher is put into use, the equipment runs stably, and the output particle size of the product has been improved obviously. The results of discharging sieving test are as follows:

| Discharging size (mm) | Productivity of ring hammer crusher (%) | Productivity of double toothed roll crusher (%) |

| -25 | 67.3 | 45.7 |

| +25–70 | 26.3 | 44.5 |

| +70 | 6.4 | 9.8 |

The comparison shows that there is an 18.2% difference between the qualified products before and after the equipment replacement, which greatly increases the output of the qualified products and creates great economic benefits for the enterprise.

Advantages of double toothed roll crusher

In what areas has the FTM Machinery tooth roll crusher been upgraded?

1. The company makes further improvements in the feed particle size, rotor diameter, rotor channel, etc., so that this series of products can adjust the corresponding rotor structure and speed to match according to different materials and feed grain levels.

2. This equipment adopts the double motor, double hydraulic coupler, and double gearbox. Hydraulic coupler overload protection and electric control overload protection can effectively prevent hard objects from damaging broken teeth.

3. The roller teeth of the crusher are arranged at a staggered angle of 15°, which has a good effect on avoiding large materials bouncing on the toothed rollers thus difficult to bite.

4. Our toothed roll crusher has the advantages of light weight, small size, low height of the whole machine, large particle size, and strong crushing capacity.

5. Compared with other types of crushers, it is an environment-friendly machine with low crushing noise and low energy consumption.

FAQ about the double toothed roll crushers

How to safely operate and maintain the double toothed roll crusher?

- 1Except for special circumstances, it is strictly prohibited to open the crusher machine with load. After stopping, the materials in the crusher should be emptied in time.

- 2After the crusher is stuck due to large blocks or materials, the crusher should be shut down and cleaned according to the power failure locking procedure. You should never open the cover during operation.

- 3Hydraulic couplings must be filled with medium water of the specified grade, and the volume is 11.7 liters.

- 4The filling medium water must be pure and free of impurities, and softening water should be used if necessary.

- 5The hoisting of the reducer must be correctly installed according to the requirements, and it is strictly prohibited to use the stretching shaft hoisting method.

- 6Grease the bearing of the crusher once a day.

- 7Before the normal stop, the feed should be stopped first, and only after the material in the crushing chamber is removed can the stop be made.

- 8When the machine is running, operators should be one meter away from the crusher.

- 9Never do any adjustment, cleaning and maintenance during the operation of the crusher to avoid danger.

- 10In winter, you should pay more attention to the thermal insulation work of hydraulic coupler to prevent frostbite.

Parameter

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing capacity(t/h) | 3-10 | 5-20 | 10-30 | 15-40 | 20-50 | 25-70 | 30-110 |

| Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

| Model | Input Size (mm) |

Processing capacity (t/h) |

| 2PG0425 | ≤25 | 3-10 |

| 2PG0640 | ≤25 | 5-20 |

| 2PG0740 | ≤25 | 10-30 |

| 2PG0850 | ≤25 | 15-40 |

| 2PG1060 | ≤30 | 20-50 |

| 2PG1260 | ≤30 | 25-70 |

| 2PG1560 | ≤30 | 30-110 |