Slag is a byproduct of metal smelting, coal combustion and ore processing and can be recycled. It is a high-quality renewable resource containing metal oxides, minerals, impurities, and moisture.

Slag with high moisture content is not easy to store and use. A slag dryer is an industrial drying equipment designed for slag drying using advanced drum drying process.

Slag dryer for sale

FTM Machinery rotary dryer is the most commonly used type of slag dryer machine. Inside is a huge cylindrical drum filled with hot air or gas.

All the parts are designed scientifically and reasonably, with good energy-saving performance, high production efficiency, and great production benefits.

Due to their cleaning device and shovel board, slag dryers are widely used to process the dehydration of heavy wet materials.

- Blast furnace slag

- Electric furnace slag

- Steel slag

- Water slag

- Alkaline slags: Yellow feldspar, dicalcium silicate, olivine, wollastonite, etc.

- Acid slags: Pseudo-wollastonite, pyroxene, plagioclase, perovskite, titanium pyroxene, etc.

Slag dryers can also dry other industrial materials, such as coal (lignite, coke), acetylene mud, sludge, river sand, quartz sand, limestone, clay, gold ore, copper ore, dolomite, gypsum, etc.

The rotary slag dryer can dry 10 to over 1,000 tons of slag per day. FTM Machinery offers custom large slag dryers using high-temperature hot air to reduce moisture below 5%, ensuring uniform drying, low emissions, and lower costs.

| Spec./m | Capacity (t/h) | Shell Cubage (m³) | Weight (t) |

|---|---|---|---|

| 1.5×14 | 5.3–6.6 | 24.7 | 19.7 |

| 2.2×12 | 9.7–12.2 | 45.6 | 33.5 |

| 2.4×18 | 17.4–21.7 | 81.4 | 49 |

| 3.6×28 | 60.8–76.0 | 285 | 135 |

The structure and working principle of slag dryer

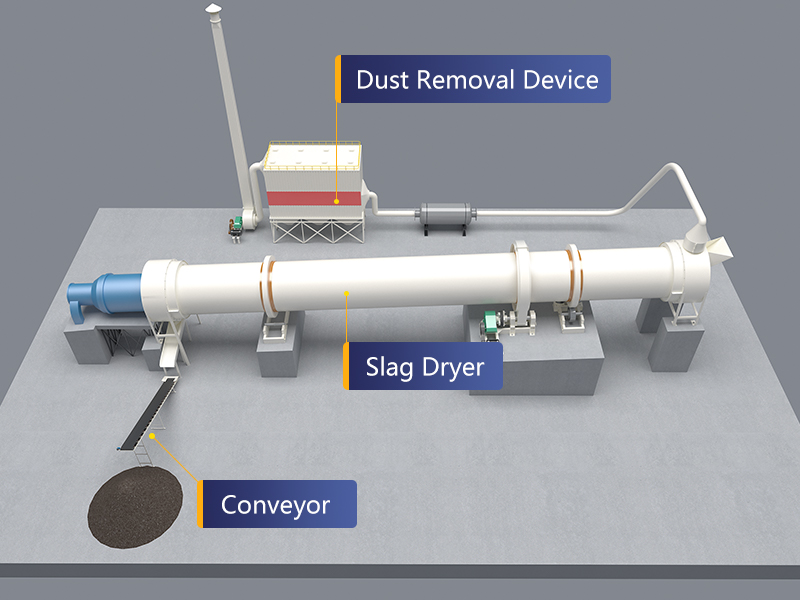

The slag dryer consists of the rotary drum, lifting plate, self-cleaning system, a transmission device, supporting device, and sealing ring. The reasonable structure and sophisticated technology make the equipment durable.

How does a slag dryer work? FTM Machinery's slag drying production line is made up of many equipment. The slag rotary dryer is the core equipment.

First, the wet slag is fed into the tilted drum dryer by a conveyor, allowing smooth entry. As the rotating drum tilts, slag moves to the lower end under the action of gravity.

Next, the hot air enters from the other end of the drum and meets or flows in the same direction as the material. During the rotation, the material is continuously thrown up by the lifting plate and fully contact with the hot air or gas, thus accelerating the drying.

The drying process can be automatically controlled, and the final moisture content is less than 2%. The dried material is discharged from the end of the drying drum, and the exhaust gas is discharged after being treated by the dust removal device.

Why choose FTM Machinery slag dryers?

As one of the world's leading slag drying equipment manufacturers, FTM Machinery has five major advantages:

1. Good drying effect

The drying drum is equipped with lifting plates of multiple shapes, which increases the contact surface between the material and the hot air flow, dries evenly, eliminates adhesion, and improves the drying effect.

2. High drying efficiency

The use of wear-resistant and high-temperature resistant materials increases the drying efficiency by more than 60%. High output, low fuel consumption, and low drying cost bring more economic benefits to the slag recycling plant.

3. Use a variety of fuels

Our industrial dryers support various heat sources, including natural gas, fuel oil, coal, biomass, and mixed fuels.

4. High feeding and discharging performance

The new cleaning device, feeding port and discharging port are adopted to effectively prevent blockage, material returning, and uneven feeding. In addition, a good sealing system can effectively reduce heat loss.

5. Stable operating state

The slag dryer adopts a new drying drum structure to make it more suitable for materials. It improves the wear resistance and production efficiency, so the dryer machine operates more reliably.

Slag dryer's applications

The dried slag has a wide range of uses. It can bring many business opportunities to the construction, cement, agriculture and other industries in various countries.

- China: Mainly used in the cement industry, it can produce coarse aggregates for concrete, concrete additives, slag cement, and slag bricks.

- Japan and Australia: Used in highway construction, it can produce road base materials, railway track materials, etc.

- South Korea: Used in blast furnaces and sintering processes to produce steel, slag wool and other insulation materials.

- European countries: Blast furnace slag and steelmaking slag are used as phosphate fertilizers in agriculture, and are used for soil improvement and blast furnace processes.

Customer cases about slag dryers

1. FTM Machinery slag dryer in the United States

FTM Machinery slag dryer in the United States

Customer feedback:

We chose FTM Machinery after comparing several rotary drum dryer manufacturers. The slag dryer we purchased is very profitable, recycling our plant's slag waste. The utilization rate of the dried slag is high, bringing us strong economic returns.

2. FTM Machinery slag dryer in Russia

FTM Machinery slag dryer in Russia

Customer feedback:

FTM Machinery is a large-scale company with attentive customer service. Thanks for helping me design my drying diagram, and install and test my slag dryer—it runs efficiently, saves costs, and has attracted many partners.

Frequently asked questions about slag dryers

1. Slag dryer maintenance tips

- Regular maintenance is key to extending the slag dryer machine's service life.

- a. Check the drum and liner every 6–8 hours during operation.

- b. Monitor equipment regularly and train operators in advance.

- c. After 6 months, inspect and clean the main engine, transmission system, and bearing.

- d. Use clean, well-sealed lubricant—bearings carry the load and need proper lubrication.

- e. Ensure stable operation. Keep bearing temperature under 50°C and tighten all parts after 30 minutes.

2. Why is the feeding port blocked in production?

- The slag has a certain humidity and uneven particle size, which can easily cause the lifting plate to be blocked or even burnt. There are two tips to solve this problem:

- a. Operators should check the feeding situation frequently to avoid the bulk of slags entering the slag dryer.

- b. Thermocouples should be installed at the flue pipe to monitor the temperature.

3. What should I do if the dried material cannot meet the humidity requirement?

- First, please control the feeding volume. Second, check the internal condition of the dryer. Finally, increase the heat supply.

4. Why is there a crackling sound inside the slag dryer?

- There are two reasons: one is that the material in the dryer is blocked; the other is that the temperature of the dryer is too high, causing the equipment to burn inside.

- When the material is blocked, we must immediately stop the machine and clean it. When the temperature of the dryer is too high, we must reduce the fuel supply to lower the temperature of the equipment to meet production requirements.