Wet silica sand is heavy to ship, easy to clump, and can cause product issues. But with proper sand drying, you can cut shipping costs by 15%, speed up production by 20%, and sell at a better price.

Dry silica sand is now key in glass, ceramics, fracking, and building materials. It helps you run better and sell better.

In this article, you'll learn:

- Why dry silica sand?

- Why choose a silica sand dryer?

- How to choose the right silica sand dryer for your plant?

- Case study: silica sand drying in Texas

- Conclusion: a better way to dry silica sand

Why dry silica sand?

Silica sand, also called quartz sand, is made mostly of silicon dioxide (SiO₂). It has even grain size, high purity, and heat resistance. That's why it is used in glassmaking, casting, construction, fracking, ceramics, and filtration.

Freshly mined or washed silica sand can contain up to 15% moisture. Wet sand causes several problems:

- It clumps, making feeding and transport harder

- It throws off material mix, especially in glass and mortar

- It adds weight, raising shipping costs

- It spoils more easily in storage and can freeze in cold weather

Drying the sand solves these issues. A good sand dryer helps lower costs, protect product quality, and support large-scale silica sand production.

Why choose a silica sand dryer?

When it comes to drying large amounts of silica sand, rotary sand dryers are the top choice across the industry. Here is why customers around the world trust rotary dryers from FTM Machinery:

1. High output, continuous sand drying

These machines handle from 1.9 to over 76 tons per hour, perfect for high-volume silica sand drying. The rotating drum runs 24/7, helping to break up clumps and ensure even heat distribution across all sand particles.

2. Built for fine materials like silica sand

The airflow and drum speed are adjustable to prevent over-drying or under-drying. This keeps moisture levels low—often below 0.5%—for consistent, high-quality results.

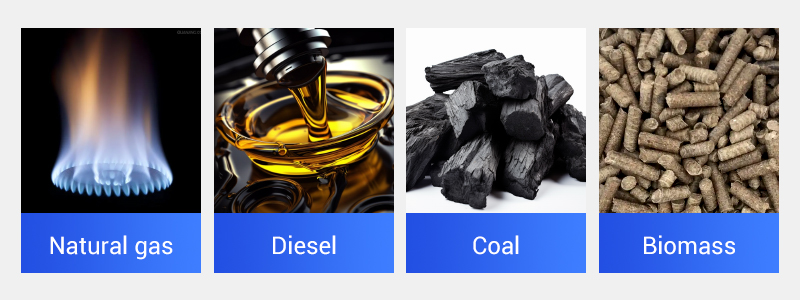

3. Flexible fuel options

Whether your facility uses natural gas, diesel, coal, or biomass, a rotary sand dryer machine can be set up to match. You can choose based on cost and local availability.

4. Strong, low-maintenance design

Made for dusty, cold, and abrasive conditions, these dryers feature wear-resistant steel and durable lifter plates. They run for years with minimal maintenance.

5. Smart control system

Each sand drying machine comes with a full PLC control system. It can monitor temperature, moisture, and rotation speed remotely—cutting labor costs and improving precision.

How to choose the right silica sand dryer for your plant?

Choosing the right sand dryer is key—not just for performance, but also for your profits.

Here are the main factors that affect your sand drying equipment setup:

| Factor | Key question | Dryer impact |

| Sand type | Coarse or fine? Any impurities? | Affects drum size and lifter design |

| Moisture level | How wet is the material before drying? | Impacts heat load and drum length |

| Drying target | What's the required final moisture? | Affects drying time and control precision |

| Hourly output | Tons per hour to be processed? | Determines dryer model and capacity |

| Fuel type | Gas, diesel, coal, or biomass? | Affects burner system and compatibility |

| Site space | Is space limited? | Impacts layout and custom design needs |

Price is important when selecting dryers, but remember: a low price doesn't always mean low cost.

Some cheap dryers may cost less upfront but lead to higher downtime, fuel, and parts expenses over time.

A reliable sand drying machine should come with:

- Installation and setup support

- Training and after-sales service

- Easy access to spare parts

- Proven results on similar materials

Here is a quick look at our best-selling models:

| Model size | Capacity (t/h) | Drum Volume (m³) |

| Small dryer | 1.9–2.4 | 9.0 |

| Medium dryer | 19.3–24.1 | 90.4 |

| Large dryer | 60.8–76.0 | 285 |

Note: Pricing varies depending on model, fuel type, and custom requirements.

Not sure what you need? Just tell us your material type and target output—we will send you a free custom recommendation. Contact us

Case study: silica sand drying in Texas

A frac sand plant in Texas was struggling with high energy costs and unstable operations. FTM Machinery provided a complete silica sand drying solution with a 100 tons/day capacity. The system included feeding, conveying, screening, dust removal, and a rotary sand dryer.

The drying equipment has run smoothly for over three years. Only one replacement of the lifter plates was needed, keeping operating costs extremely low while maintaining consistent drying quality.

Results:

- Fuel costs reduced by 18%

- Final moisture consistently below 0.3%

- 97% equipment uptime over 3 years

- Product price increased by $20 per ton

- Maintenance time under 2 hours per month

Conclusion: a better way to dry silica sand

Drying silica sand isn't just a technical step—it's a way to boost your profits. With the right rotary sand dryer, smart layout, and quality components, you can dry faster, save energy, and deliver a product your customers can trust.

If you're looking for a sand dryer for sale or need help designing a custom sand drying system, contact our engineering team today.