Why use mineral dryer equipment?

Mineral drying is a crucial step in the mineral processing workflow. It is primarily used to remove excess moisture from raw ores before further processing or transportation.

Mineral drying offers several advantages:

- Reduced transportation costs: Dried minerals and ores weigh less, cutting down transportation costs and improving logistics efficiency.

- Improved processing efficiency: Dried minerals flow more smoothly, reducing the risk of blockages and making them easier to grind, separate, or further process.

- Enhanced product quality: Removing moisture helps prevent clumping, mold, and degradation—preserving particle integrity and maintaining consistent product quality.

- Maintained product integrity: Over-drying causes mineral breakdown and dust issues; under-drying leads to clumping or microbial growth. Reaching optimal moisture levels is essential for both stability and usability.

One of the most effective mineral drying methods is drying equipment, widely applied in mineral drying—particularly for minerals like iron ore and potash.

This ore dryer is a rotary dryer using a drum drying process. The wet ore enters one end of the rotary drum and moves through a heated air or gas stream, where moisture is gradually evaporated.

Though similar in appearance to other industrial drying machines, the mineral dryer is engineered for ore drying. They offer higher resistance to abrasion, corrosion, and heat for reliable performance in tough conditions.

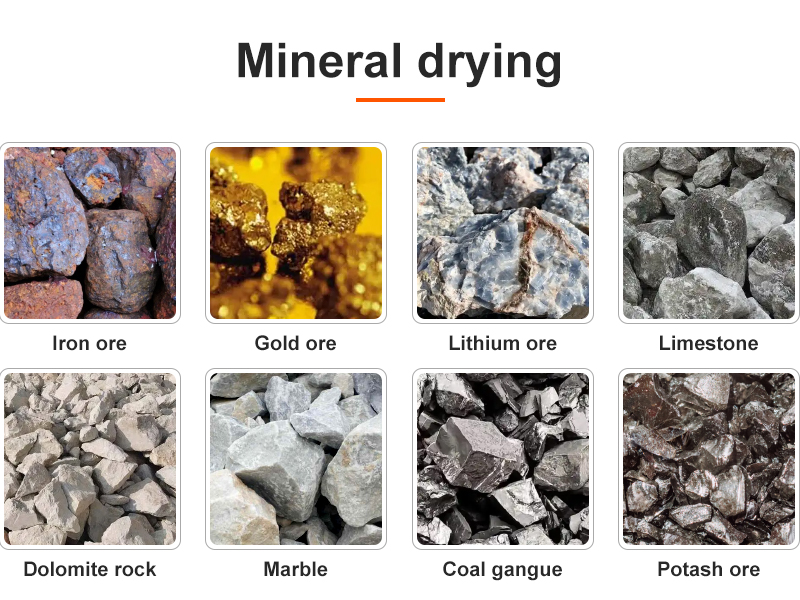

What minerals can be dried?

Due to the diversity of minerals and their processing requirements, mineral drying is often necessary at various stages—from raw ore to concentrate to finished product.

With FTM Machinery's mineral dryers, you can dry a wide range of materials, including:

- Metallic ores: Iron ore, copper ore, gold ore, bauxite, molybdenum, tungsten, and more.

- Non-metallic minerals: Limestone, clay, bentonite, kaolin, gypsum, dolomite, talc, etc.

- Salts and other minerals: Potash, phosphate rock, fluorite, and others.

- By-products and secondary minerals: Ore slurry, slag, fly ash, and other moisture-rich, fine-grain materials.

These dryer machines provide stable, efficient drying performance across various sectors including mineral beneficiation, metallurgy, fertilizers, cement, and construction materials.

FTM Machinery mineral dryer equipment for sale

As one of the leading industrial dryer manufacturers, FTM Machinery designs rotary dryers tailored for mineral applications, considering:

- Material Durability: Components are made from carefully selected materials that resist constant wear and corrosion.

- High Throughput Capacity: Designed to handle large volumes of mineral feed.

- Heavy-Duty Construction: Equipped with robust motors, gears, bearings, and structural elements to ensure long-term operational reliability.

- Custom Configuration: Drum dimensions, retention time, and airflow setup (co-current or counter-current) are tailored to the mineral's properties—avoiding over-drying or discoloration.

Thanks to the high processing capacity and consistent drying performance across variable mineral types, FTM Machinery mineral dryers are widely used in Australia, the U.S., Brazil, Russia, and beyond.

Popular models of the mineral dryer machine:

| Spec./m(Dia.×Length) | Shell Cubage(m³) | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Φ1.5×12 | 21.2 | 4.5–5.7 | 700–800 |

| Φ1.8×14 | 35.6 | 7.6–9.5 | 700–800 |

| Φ2.2×14 | 53.2 | 11.4–14.2 | 700–800 |

| Φ2.4×20 | 90.4 | 19.3–24.1 | 700–800 |

| Φ3.2×25 | 201 | 42.9–53.6 | 700–800 |

| Φ3.6×28 | 285 | 60.8–76.0 | 700–800 |

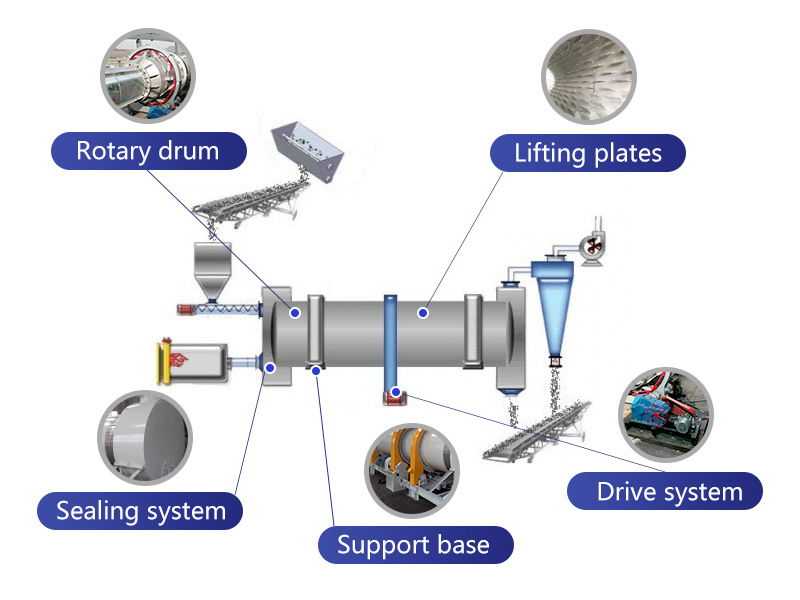

Structure and working principle of the mineral dryer

Structure overview

The mineral dryer is a horizontal rotating drum. This drum dryer diagram consists of the drum, lifting plate, transmission device, support device, and sealing ring. Its compact structure ensures stable operation and easy installation, maintenance, and use.

1. Rotary drum

The rotary drum is the core component, welded from high-temperature and corrosion-resistant alloy steel or manganese steel, with wear resistance four times higher than standard steel.

The inner wall is equipped with special coatings or linings based on material properties. The rotating motion agitates the ore, ensuring full exposure to hot air, and achieving efficient heat transfer and water evaporation.

2. Lifting plates

There are multiple sets of lifting plates evenly distributed in the cylinder, whose function is to continuously lift and throw the material so that it is evenly distributed in the airflow in the cylinder.

This design effectively increases the contact area between the mineral and the hot air, improves the drying efficiency, and avoids material agglomeration or sticking to the wall.

3. Drive system

The drum dryer is driven by an electric motor, which transmits power to the cylinder through a reducer and coupling to achieve stable rotation.

The drive system ensures smooth, efficient, and overload-protected rotation under continuous heavy-duty operation.

4. Support base

The drum is installed on two or more sets of support rollers and thrust rollers, which carry the combined weight of the drum and material load, ensuring its stability and safety during operation.

This structure is usually made of carbon steel or alloy steel, with good load-bearing capacity and fatigue resistance.

5. Sealing system

To prevent heat loss and dust leakage, an efficient sealing system is installed at both ends of the dryer cylinder.

This sealing system can maintain sealing under high temperature and rotation conditions, improve thermal efficiency, and ensure environmental protection standards.

How does a mineral dryer equipment work?

The mineral drum dryer principle is based on the continuous material agitation within a heated rotating drum. Hot air flows through the drum, making full contact with the material to evaporate moisture and preserve material quality when needed.

The slightly inclined drum uses gravity to move mineral, while rotating lifting plates lift and scatter ore for better hot air contact and heat transfer. This rolling motion also breaks up clumps and promotes even drying—resulting in uniform particle size and smoother surfaces.

Why choose FTM Machinery mineral dryer equipment?

The mineral dryer is an ideal industrial dryer machine that meets the harsh processing conditions of the industry. FTM Machinery has been committed to providing mineral drying solutions to meet the various needs of the mineral processing industry.

Benefits of choosing FTM Machinery mineral dryer equipment:

1. High drying efficiency

Our dryers feature multiple lifting plates that maximize contact between the material and hot air, achieving thermal efficiency up to 80%. Production capacity ranges from 1.9 to 76 tons per hour.

2. Fast and consistent drying

Drying time ranges from 0.5 to 5 seconds, ensuring uniform and rapid treatment of various materials. While theoretical final moisture can reach zero, actual reduction depends on the initial moisture content.

3. Flexible temperature control

Temperature settings can be adjusted to suit different materials — from high-temperature applications like mineral sands (up to 800°C) to low-temperature materials such as sawdust and gypsum (below 300°C).

4. Durable, wear-resistant construction

The drying drum and internal lifting devices are made of wear-resistant manganese steel, offering 3–4 times the lifespan of ordinary steel plates. This ensures long-term, continuous operation.

5. Multiple heating sources are available

Choose from natural gas, coal, anthracite, biogas, diesel, methane, or biomass fuel — allowing for the most cost-effective and locally available option for your site.

6. Eco-friendly design with full automation

The fully automated drying process precisely controls temperature, time, and moisture, with an outlet temperature below 60°C for easy storage or packaging. A sealed system prevents heat loss and dust, supported by dust collectors and eco-friendly, energy-saving heat and exhaust systems.

Customer cases

1. Russia limestone drying process

The moisture content of limestone in the quarry varies greatly, ranging from 5% to 15% or even higher. It needs to go through a series of processes before it can be finally used in production. Drying is one of the most important processes.

Project background:

To ensure the quality of limestone raw materials, a cement plant in Russia is equipped with a mineral drying process system, which is specially used for limestone drying to improve the clinker production efficiency. The capacity is 10 tons per hour.

Dryer application:

We provided a high-temperature hot air drying system using indirect heating to avoid direct contact between limestone and combustion gases. It preserved the limestone's chemical stability. Multi-stage drying and a custom lifting plate design enabled uniform material movement and moisture removal.

Result:

The moisture content was reduced to 0.5%–5% depending on the final use. Drying efficiency improved significantly, increasing overall production line capacity by 20% while maintaining the chemical integrity of the limestone.

2. Australia iron ore drying process

Australia is one of the world's largest iron ore exporters. Many iron ore plants require the iron ore drying line to dry iron ore, iron ore pellets, iron powder, iron scrap, copper concentrate and refined iron ore, iron oxide, and other similar materials.

Project background:

An iron ore drying plant introduced the FTM Machinery iron dryer to improve the drying efficiency of iron ore concentrate. The feed size of the concentrate is within 30 mm, and the moisture content is 11–15%. Before entering the iron ore pelletizing process, the moisture must be dried to 0.5%–1%.

Dryer application:

The rotary drum iron ore dryer utilizes direct hot air circulation to rapidly reduce moisture. The rotating drum ensured a uniform mixing of iron concentrate and additives like bentonite, optimizing the material for the next stage. The capacity is 20 tons per hour.

Result:

The final moisture content was controlled to 0.5%–1%. With a discharge temperature below 50°C, no cooling was required. The dried iron ore could be directly fed into the iron ore pelletizing process.

Frequently asked questions about mineral dryer equipment

1. Can corrosive or easily agglomerated minerals be dried with the mineral dryer?

- Yes. FTM Machinery mineral dryers use corrosion-resistant stainless steel and specialized lifting plate designs, making them suitable for challenging materials, including:

- a. Iron ore (pyrite): Prone to oxidation and corrosion

- c. Gypsum: Contains calcium sulfate, clumps easily when wet

- d. Iron powder: Highly absorbent and prone to clumping; requires uniform heating and anti-corrosion materials

- e. Potash minerals: High salt content can corrode equipment

- f. Bauxite: May contain acidic compounds and high moisture, leading to agglomeration

- g. Coal slurry and coal powder: Risk of moisture absorption, corrosion, and explosion—requires proper ventilation and explosion-proof design

2. Does mineral dryer equipment consume a lot of energy? How to reduce energy consumption?

- Mineral drying process consumes a lot of energy, mainly in heat source and mechanical operation. The energy consumption can be reduced through:

- a. Efficient heat exchangers to improve thermal utilization

- b. Optimized airflow and material flow paths to shorten drying time

- c. Waste heat recovery systems

- d. Energy-saving motors and drives

- e. Automated control systems to precisely regulate temperature and airflow, avoiding over-drying