Application fields of fine crushers

The fine crusher is mainly suitable for grinding and processing in metallurgy, building materials, chemical, mining, railway, water conservancy and other industries. It is used before the ball mill to increase the production efficiency of the ball mill by 50%.

It is especially suitable for fine and medium crushing of materials with hardness below 9 such as quartz, feldspar, calcite, marble, ceramics, iron ore, copper ore, gangue, phosphate rock, granite, basalt, silicon carbide, corundum, insulation materials and other brittle materials.

Performance advantages of fine crushers

Performance advantages of fine crushers

- 1 High crushing efficiency. The use of grate plate, rigid hard extrusion crushing and solid rotor body greatly improve the crushing efficiency.

- 2 Good crushing effect. The fine crusher can arbitrarily control the discharging size of materials, so the required material size can reach more than 95% and ideal material size control and classification can be realized.

- 3 Small wear parts wearing. Compared with hammer crushers and impact crushers, it only wears the hammerhead, while the wheel core and hammer frame have no wear.

- 4 Simple installation. It is light in weight, diverse in installation (removable installation) and easy to operate.

- 5 Convenient maintenance. It only needs to lift the upper case and open the lowercase during maintenance. A person can complete a comprehensive inspection and maintenance of the whole machine within 20 minutes with a wrench.

- 6 Timely discharging. Three discharging channels are adopted to discharge qualified materials in time.

- 7 Adjustable discharging. The discharging granularity of the fine crusher can be adjusted, and the adjusting plate can be turned over at both ends.

Structure of the fine crusher

The fine crusher is mainly composed of the rotary part, guard plate and box part.

Some non-overlapping hammer carriers are arranged on the wheel core of the rotary part. The hammer head, whose width is larger than the hammer carrier and the wheel hub, is fixed on the hammer carrier. The wheel core is composed of several wheel hubs, which are fixed on the main shaft. The two ends of the main shaft are supported on the frame with rolling bearing seats.

Structure of the fine crusher

The guard plate is fixed on the box body in several pieces to protect the box body from wear and form different types of impact crushing cavity.

The box body is divided into upper and lower parts, which are connected by bolts for easy disassembly and maintenance.

The working principle of fine crusher

The material is sent to the cavity from the inlet and falls on the high-speed rotating hammer head. The material is initially crushed between the hammer and the impact plate.

The working principle of fine crusher

After the material is repeatedly hammered and impacted with high frequency, it forms a pile on the median septum, then falls on the material plate of the high-speed rotating lower rotor. Finally, it is thrown to the impact plate at high speed to be impacted, crushed and ground by the mobile plate hammer.

Therefore, the material undergoes multiple compound pulverization, scouring and grinding in the process of falling by its own weight to achieve an ultra-fine effect, and then is discharged through the discharging port.

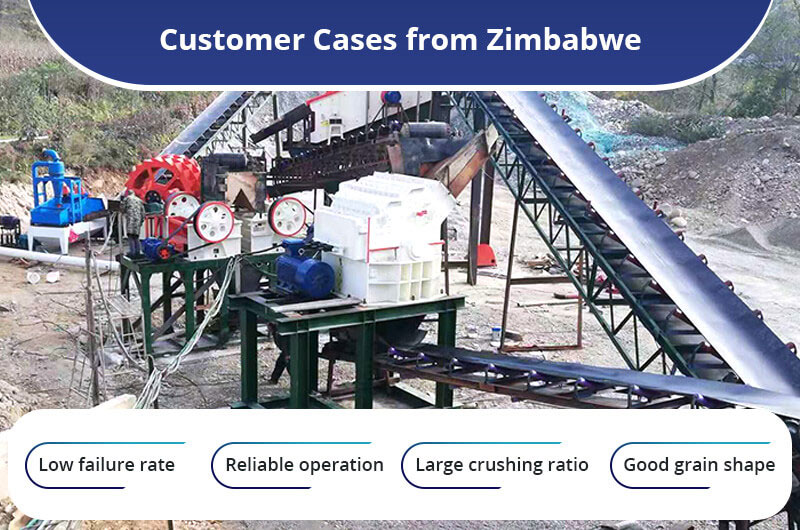

Customer case—fine crusher for sale in Zimbabwe

FTM Machinery designed a 40 tons per hour river pebble sand production line for Mr. Moyo from Zimbabwe, which meets the standard of building sand. It has the characteristics of low failure rate, reliable operation, large crushing ratio, long service life of the vulnerable parts hammer, small particle size and good grain shape.

FTM Machinery fine crusher for sale in Zimbabwe

It is reported that the customer has got his lost within three months of production and started to make money in the fourth month.

| Materials | River pebble |

| Capacity | 40 t/h |

| Feeding size | ≤15 mm |

| Finished products | 0–5 mm |

| Equipment configuration | Silo, YTS1500×6000 trommel screen, PXJ1010 fine crusher, KS2900 sand washing machine, conveyors |

Parameter

| Model | PXJ0804 | PXJ0806 | PXJ0808 | PXJ1010 | PXJ1212 | PXJ1414 | PXJ1616 | PXJ1818 |

| Rotor diameter×width(mm) | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Limestone(t/h) | 5-45 | 7-55 | 10-65 | 15-75 | 20-110 | 25-150 | 30-200 | 40-260 |

| Power(kW) | 37 | 45 | 45 | 55 | 110 | 160 | 250 | 315 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Rotor diameter×width(mm) | Limestone(t/h) | Power(kW) |

| PXJ0804 | 800×400 | 5-45 | 37 |

| PXJ0806 | 800×600 | 7-55 | 45 |

| PXJ0808 | 800×800 | 10-65 | 45 |

| PXJ1010 | 1010×1010 | 15-75 | 55 |

| PXJ1212 | 1200×1200 | 20-110 | 110 |

| PXJ1414 | 1400×1400 | 25-150 | 160 |

| PXJ1616 | 1600×1600 | 30-200 | 250 |

| PXJ1818 | 1800×1800 | 40-260 | 315 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.