Do you know that a modern glass bottle would take 4000 years or even longer to decompose if it is in a landfill? Have you ever heard that glass bottles can be 100% recycled and reused endlessly?

Yes, it is true. That is why more and more glass recycling companies emerge nowadays. You can recycle glass not only to crush it into recycled glass sand, but also to make new glass bottles.

Which kind of waste glass products can be recycled?

We all know that there are different types of glass products like glass bottles, window glass, tempered glass, glass jars, etc., but they cannot be put together to recycle. Because window glass and tempered glass cannot be melted normally in most ordinary glass-melting furnaces and may cause quality problems for new glass products.

Waste glass bottles can be 100% recycled and reutilized endlessly without any loss in purity or quality. Glass bottles mainly include glass wine bottles, glass beverage bottles, glass jars, broken glasses, perfume bottles, and so on.

However, if you want to make recycled glass sand only, there is no limit on glass bottle colors. It is ok even if you mix and crush them together.

How to recycle glass bottles to earn more money?

There are two ways to make money from glass recycling. One is crushing glass to sand with a glass crusher to produce cheaper aggregate substitution. The other is selling your glass bottles and jars to the recycling plants for making new glass products.

If you only have bottles and do not operate a complete glass recycling plant, the first choice is more profitable than the second, and it is easy to get recycled sand.

Price comparison between waste glass bottles and recycled glass sand:

| Country | Glass bottles (USD per ton) | Recycled glass sand(USD per ton) |

| USA | 10-40 | 50-100 |

| UK | 4.9-31.6 | 55-150 |

| India | 0.21-0.3 | 13.597 |

| South Africa | 0.5-1 | 15 |

Note: Glass bottle price and other details may vary based on different product sizes and colors.

Process for making recycled glass sand

Recycled glass sand, also known as crushed glass sand, has several potential uses. Compared with the new bottle produced by used glass recycling, making recycled glass sand is much easier, and even anyone can make it at home. The following steps for turning glass bottles into recycled glass sand:

- 1 Sorting: The waste glass will be mixed with other materials or sundries, which need to be sorted first.

- 2 Cleaning: Clean the glass bottles thoroughly to remove any dirt, labels, or debris.

- 3 Crushing: Large glass bottles need to be crushed first, and then finely crushed. Crush the glass bottles into small pieces using a crusher.

- 4 Sieving: The recycled glass sand is sieved to ensure the desired size. This can be done using a vibrating screen.

Among them, crushing is the most important link. Which equipment is suitable for crushing waste glass?

Although there are many different types of crushers that can process glass bottles like jaw crushers, roll crushers, impact crushers, etc., only hammer crushers can ideally turn glass bottles into recycled glass sand.

Why hammer crusher is the best machine to make glass sand?

The difference between a hammer crusher and other glass crushing equipment is that breaker pate of a hammer mill is a continuously moving belt of manganese steel links. Used glass products are fed to the hammer points and then discharge from the grates.

Enormous crushing power can produce uniform high-quality products without the necessity of using several units to obtain the necessary production.

Hammer glass crusher is in a small footprint and inexpensive, especially suited for crushing your used glass bottles and jars at home. Besides, its simple structure and installation make an easy operation.

Recycled glass sand is often used as an aggregate or gravel substitution, which is cheaper, and thus needs no higher standards. That means you can crush all your bottles together no matter what colors they are.

Glass hammer crusher price: Get Latest Price

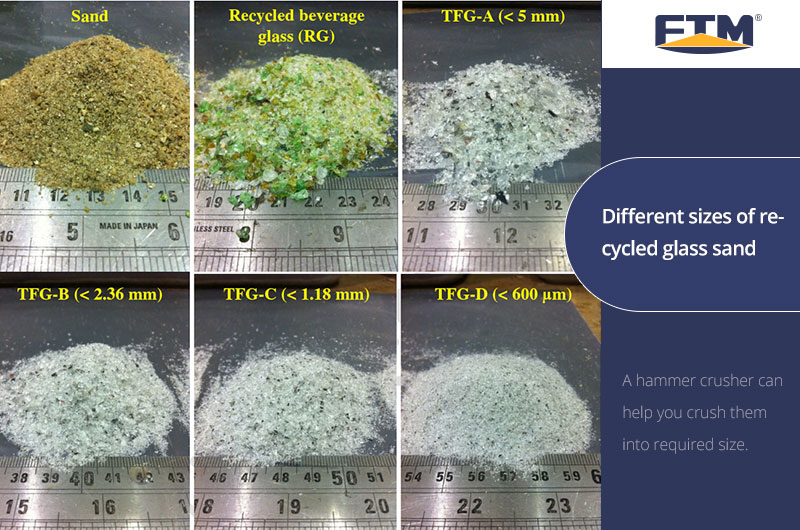

Common sizes of recycled glass sand

Waste glass comes in a variety of sizes, from a fine powder and sand grain pieces to small and larger aggregates. Due to different requirements on particle sizes, you can adjust this equipment from minimum size to maximum size.

| Glass sand types | Particle size |

| Glass Sand | 0.1-0.3 mm |

| Recycled beverage glass (RG) | 0.5-1.5 mm |

| TFG-A | 5 mm |

| TFG-B | 2.36 mm |

| TFG-C | 1.18 mm |

| TFG-D | 600 μm |

What can recycled glass sand be used for?

Glass bottles are crushed and separated for use in various projects, and recycled glass sand is one of the best aggregates.

Wide applications of recycled glass sand

- Construction (3-5 mm coarse sand): Recycled glass sand can be used as a substitute for traditional construction materials, such as sand or gravel.

- Glass aggregate (<2 mm): It can be used to create concrete and asphalt or as a bedding material for utilities.

- Glass decoration: Used as a decorative landscaping material for pathways, driveways, and gardens.

- Sand blasting media: Used as an abrasive material for blasting applications, such as cleaning surfaces for painting or coating.

- Glass manufacturing: Used in the manufacturing of new glass products, such as bottles, jars, and other containers.

- Coastal restoration: Crushed glass is considered as a partial replacement for the sand on Florida's eroding beaches.

- Filtration: Used as a replacement for traditional filtration media, such as a filtration material for water and wastewater treatment.

Why is recycled glass sand one of the best aggregates?

- 1It is cheaper than aggregates made of stone but also performs well in the same applications.

- 2Using glass sand can save natural aggregate resources like natural sand.

- 3Greater coverage per ton because it has lower bulk density than sharp sand.

- 4It is non-toxic and inert thus no harm to the environment.

- 5It can be used in poor weather conditions.

How to make new bottles from used glass bottles?

Compared with the recycled glass sand making process, turning waste glass into new glass products is more complicated because it needs at least 6 processes.

- 1Color sorting: Generally, there are three colors needed by a recycled plant, flint (clear), amber (brown), and green. They are the most common colors used for new glass bottles.

- 2Cleaning: The sorted glass is cleaned to remove impurities, such as metals, bags, boxes, cans, labels, caps, non-ferrous aluminum ceramic, and other contaminants.

- 3Crushing: The glass then is fed into a crusher to break into small pieces.

- 4Melting: Calcine the crushed glass in a furnace at around 1500 degrees.

- 5Reshaping: Reshape the liquid glass to make new bottles using specialized equipment, such as molds and blowers.

- 6Cooling: The newly-formed glass bottles are then cooled and undergo additional finishing processes, such as labeling and packaging.

Conclusion

No matter which way you choose to recycle your glass, they are all profitable and only different in how much profit you can get. Which way and which glass crusher suits my project?

If you are running a glass recycling plant, the optimal choice is to produce new glass bottles. Because you have a wealth of raw glass materials and complete facilities.

If you are an aggregate supplier or want to crush your glass bottles at home, only a glass hammer crusher would be your best choice. Because it can not only reduce your cost but produce profitable glass sand.