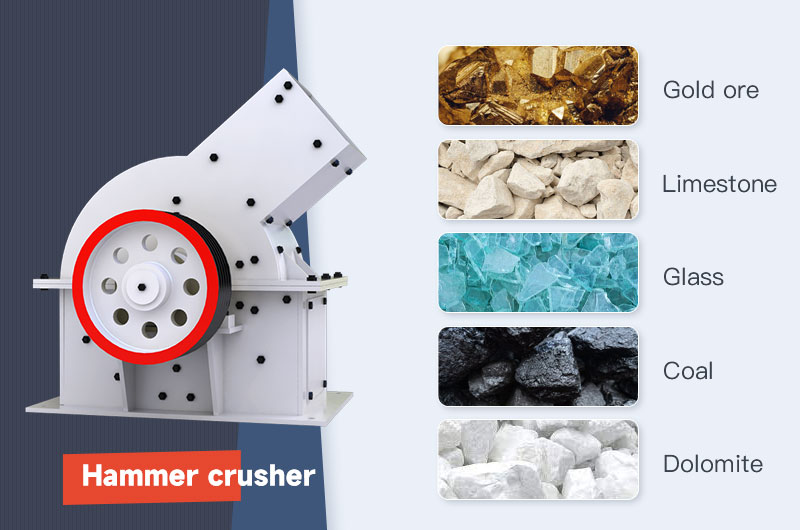

A hammer crusher is a kind of equipment for medium and fine crushing of medium hardness materials in the form of impact. It processes gold ore, limestone, glass, coal, cement, gypsum, granite, dolomite, barite, etc.

Compared with other crushers, hammer mill has the advantages of one-time crushing, high production capacity, and easy maintenance. Its feed size is 600-1800mm. The output size is 25mm or below. The maximum productivity is 3, 000 t/h. And the hammer crusher price is as low as $1680.

With a wide usage application, grasping some solutions to the common faults of the hammer mill crusher is very necessary.

1. High temperature of bearing

Reasons:

a. Lack of grease or too much grease;

b. The bearings were broken.

Solutions:

a. Regularly check the hammer mill, add grease if insufficient. Bearing greases should be 50% of the volume of its space;

b. Clean the bearings regularly and replace the bearing timely.

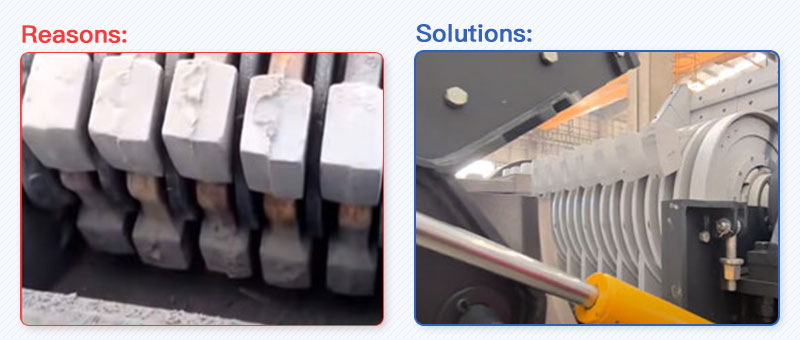

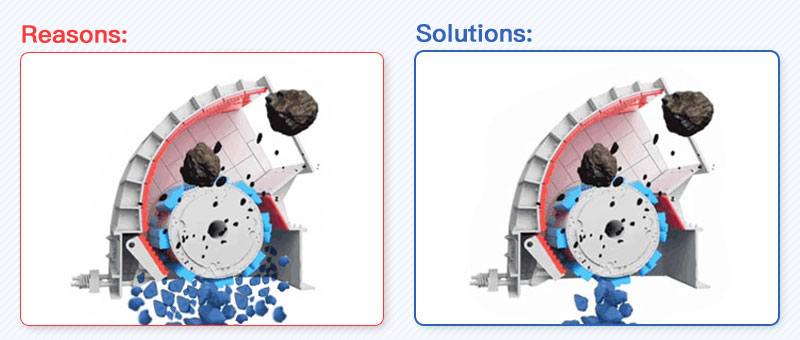

2. The discharge particle size is too large

Reasons:

a. The hammer head is seriously worn;

b. The screen bar is broken.

Solutions:

a. Replace the hammer head;

b. Replace the screen.

3. Production reduction

Reasons:

a. The hammer head is seriously worn;

b. The gap of the screen is blocked;

c. The feeding is uneven.

Solutions:

a. Regulate the operation, adjust the speed and quantity of feeding;

b. Stop and clean up the screen gap in the plug;

c. Adjust the feeding mechanism of the hammer mill.

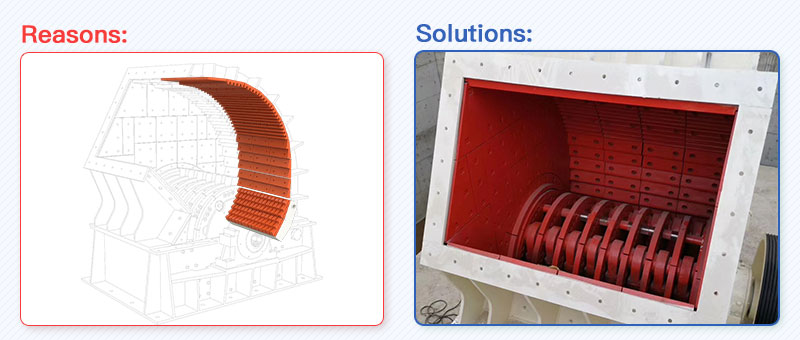

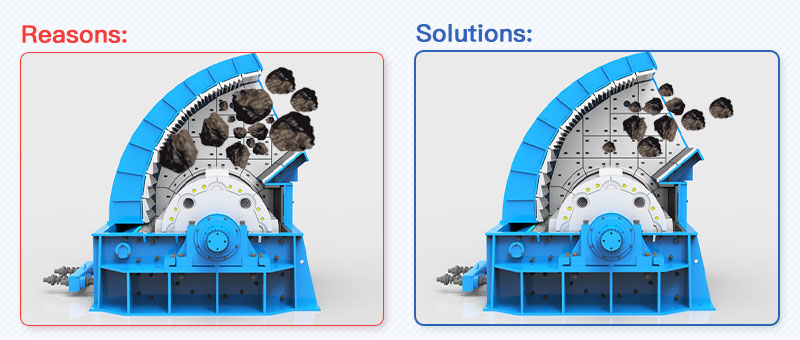

4. A knocking sound inside the machine

Reasons:

a. Non-broken materials enter the hammer mill crusher;

b. The lining fastener is loose and the hammer strikes the lining;

c. Hammer or other parts are broken.

Solutions:

a. Stop and clean up the crushing cavity;

b. Check the fastening of the lining plate and the gap between the hammer and the screen;

c. Replace the broken parts.

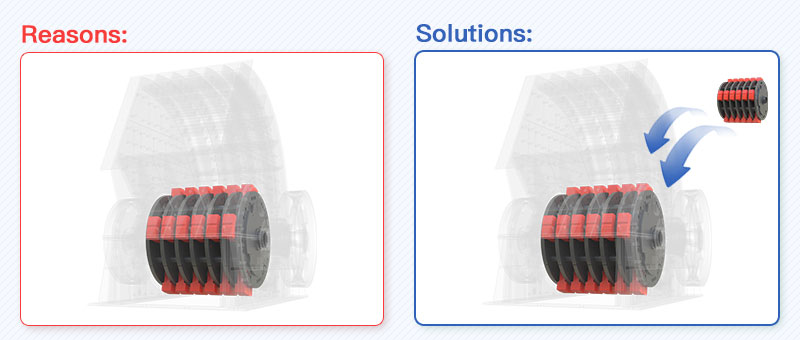

5. Hammer crusher vibration

Reasons:

a. Hammer broken, rotor imbalance;

b. Pin roll bending, broken;

c. Triangular plate or disc cracks;

d. Anchor bolt lose.

Solutions:

a. Remove the hammer head and choose hammerhead by weight, so that each of the total weight of hammer on each hammer shaft is equal to the total weight of hammer on its relative hammer shaft. That is the static balance to meet the requirements;

b. Replace the hammer and pin;

c. Welding repair or replacement;

d. Tighten the loose bolts.

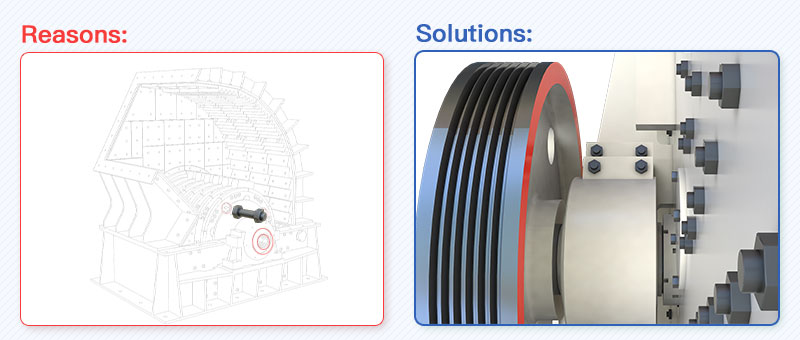

6. The elastic coupling produces a tapping sound

Reasons:

a. Loose pin shaft;

b. Elastic ring wear.

Solutions:

a. Stop the hammer mill and tighten the pin nut;

b. Replace the spring ring.

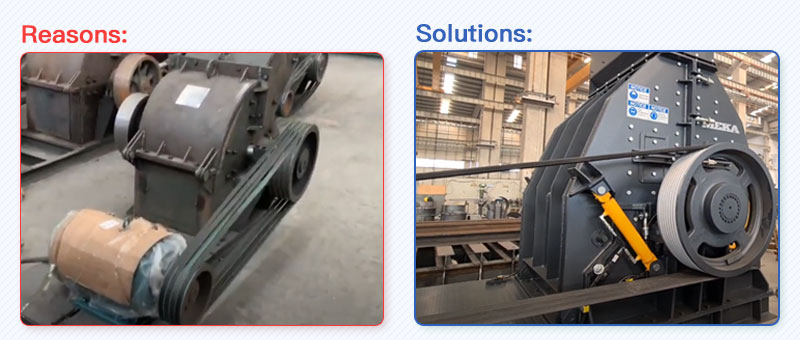

7. The hammer mill crusher host suddenly shuts down

Reasons:

a. The discharge port is blocked, causing a full cavity to block the material;

b. The V-belt driving the pulley is too loose, causing the belt to slip;

c. The eccentric shaft tightening bush is loose, causing no gap on both sides of the bearing seat of the frame, making the eccentric shaft stuck and unable to rotate;

d. The working site voltage is too low, and the host is unable to break after encountering large materials;

e. The bearing is damaged.

Solutions:

a. Clear the blockage of the discharge port, ensure that the discharge is unblocked;

b. Tighten or replace the V-belt;

c. Reinstall or replace the tightening bushing;d. Adjust the voltage at the worksite to make it meet the requirements of the host’s working voltage;

e. Replace the bearings.

8. The pulley rotates slowly, the motor vibrates, and the current is large

Reasons:

The feed is too much and uneven, the V-belt is loose, and the material is too wet, resulting in “loss of rotation”.

Solutions:

The feeding of hammer mill should be uniform and reduce the feeding. After the feeding current returns to normal, tighten the motor anchor screw, then crush the material after drying.

9. Hammer crusher V-belt layering

Reasons:

The belt will age if the tension is too tight.

Solutions:

You need to cut off the part that has dropped layers, adjust the belt tightness, and then replace the belt.

As a supplier with nearly 30 years of manufacturing experience, Ftmmachinery produces and sells various high qualified hammer crusher machines. Please feel free to contact us for more information.