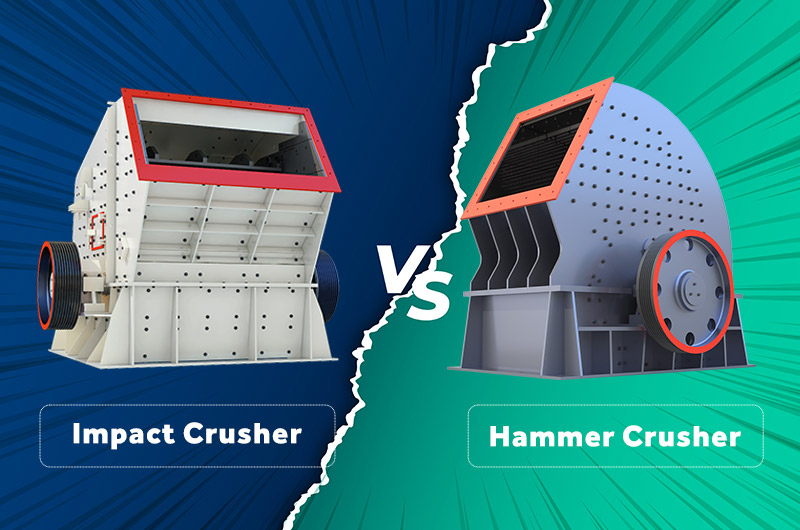

The impact crusher and hammer crusher both use the impact principle to crush materials, and the product has an excellent grain shape. They look similar, but are different in many ways. So, which is better?

This blog will compare them in materials, price, structure, output, grain shape, wear parts, etc.

1. Different in materials

The impact crusher is designed for the crushing of hard and high-moisture materials. It is very suitable for highway, water conservancy, railway, airport, and other industries.

The hammer crusher is used for the large-scale and high-yield production lines. It is simple and efficient by crushing and forming at one time.

| Types | Impact crusher | Hammer crusher |

| Material hardness | Medium-hard materials with low toughness and high brittleness | Medium-hard and brittle materials |

| Material with high moisture content | Applicable |

Unapplicable (Water content should not exceed 10%) |

| Compressive strength of materials | ≤ 350 MPa | ≤ 200 MPa |

| Feed size | ≤ 800 mm | ≤ 1800 mm |

| Common materials | Granite, concrete asphalt, construction waste, gypsum, dolomite, clay, river pebble, etc. | Glass recycling, limestone, quartz, slag, coal, etc. |

Not sure whether your materials can be processed or not? Free Sample Testing!Contact us.

2. Different in price

Impact crusher price: $1, 000 (the lowest price).

It is mostly used as the secondary crushing equipment, so a coarse crusher is also needed in the crushing. It crushes small materials that discharge from the jaw crusher.

Hammer crusher price: It has many models with the lowest price of $976. Among them, the heavy hammer crusher has a larger granularity and is sold $5, 000-$180, 000.

Hammer crusher can form a single production line to achieve one-time molding, which can simplify the crushing process and save 40% of the cost.

3. Different in structure

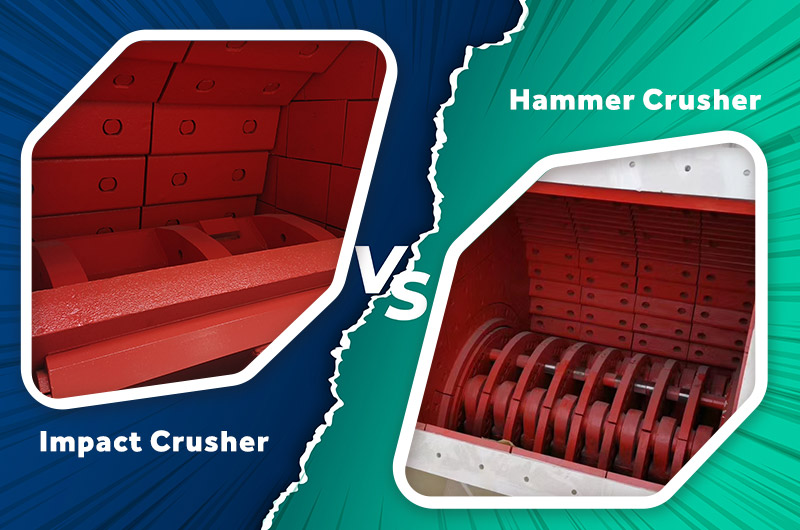

| Structure design | Impact crusher | Hammer crusher |

| Crushing cavity |

2 or 3 large crushing cavities. Advantage: the crushing is more sufficient. |

1 small crushing cavity. Advantage: good sealing, solve dust leakage. |

| Direction of plate hammer/hammer head | The plate hammer moves from the bottom to the top to crush, then it throws material onto the upper impact plate. | The hammer head strikes and crushes along the direction in which the material falls. |

| Rotor link |

The plate hammer is fixed on the rotor. Feature: large speed and kinetic energy. |

The hammer head hangs in the air and crushes materials individually. Feature: limited speed and kinetic energy. |

| Output size adjustment |

Adjust the rotor speed; Adjust the rotor diameter; Adjust the opening size of the distributor; Adjust the gap of the grinding chamber. |

Adjust the screen gap of the sieve plate. |

4. Material blockage

Impact crusher: It is not easy to cause material blockage.

Reasons:

- It can be equipped with a heating device to prevent blockage due to adhesion.

- There is no grate at the bottom. The product size is determined by the gap between the impact plate and plate hammer. Therefore, it can process high-moisture materials.

Hammer crusher: It is equipped with a bottom sieve plate, which increases the possibility of material blockage.

5. Different in output

Impact crusher: Although the grain shape is more rounded after 2-3 shaping processes, multiple impacts seriously affect the output (productivity).Hammer crusher: It has a higher output, up to 3 times that of an impact crusher. Therefore, it is often used in large-scale and high-yield production lines.

6. Different in grain shape

Impact crusher: The crushing ratio is above 50. The discharge is cubic, with uniform particle size, without tension and cracks. And the fine powder and dust content are low.

So, the impact crusher is the final crusher to produce concrete aggregate for the antiskid pavement of the high-grade highway.

Hammer crusher: The crushing ratio is large (generally 10-25, even to 50). The output size is 25 mm or less. The product contains more needles, flakes, and powders.

7. Different in wear of wear parts

Whether for the impact crusher or hammer crusher, the plate hammer and hammer head are the main wear parts.

Impact crusher: It wears little during the crushing, as the wear occurs only appears on the side of the material, and its metal utilization rate can reach 45%-48%.

When crushing limestone, the plate hammer is not seriously worn. However, when crushing granite with high hardness, it needs to be replaced constantly.

Hammer crusher: Due to the hanging state of hammer head, the wear occurs at the top, front, back, and side. Compared with the plate hammer, the hammer head is more seriously worn, and its metal utilization rate is 35%.

Besides, the rotor of hammer mill may also be worn. The bottom screen plate can be severely worn so you need to replace all the grids, which is very complicated.

8. Equipment maintenance

How to maintain the impact crusher?

- Only 6 plate hammers are installed on the rotor. The plate hammer is easy to replace, and it only takes one shift to replace one set.

- Replacing the grinding rod only takes a few minutes, which can save you more time and cost.

- Due to the large hammer head and strong vibration force during operation, its balance needs to be calibrated during installation in case of any danger.

How to maintain the hammer crusher?

- There are more than 100 hammer heads. Replacing a set of hammer heads requires a lot of time and labor. And the maintenance cost is high.

- Replacing the bottom sieve plate of hammer mill is also extremely troublesome.

9 Faults and Solutions of Hammer Crusher

Conclusion

How to choose between the impact crusher and hammer crusher? You should choose according to the actual production situation.

| Types | Impact crusher | Hammer crusher |

| Hard materials | √ | |

| High requirement for final grain shape | √ | |

| High demand for output | √ |

Ftmmachinery has been engaged in the production of crushing equipment for nearly 40 years. Contact us to customize your best crushing plant !Contact us