What is a disc granulator?

A disc granulator, also known as a disc pelletizer, pan granulator, or pan pelletizer, is a versatile machine used to create granules from various materials. The particle size of the transported material is not greater than 50 mm, which is not suitable for transporting viscous and difficult-to-flow materials.

Disc granulator machines are commonly used in the chemical fertilizer industry, including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, and compound fertilizer. They also are adapted for petrochemical, pharmaceutical, mineral processing, building materials, food, ceramics, plastics recycling, and other fields.

Why do you need granulation?

The purpose of granulation mainly has the following points:

- Improve the flow performance of the powder mixture

- Reduce the possibility of material sticking and caking

- Reduce dust hazards to people and the environment

- Prevent separation of material components and the material color becomes more uniform

- Improve the quality of materials by adding plasticizer, dispersing agent, grafting agent, etc. in granulation

- Control the porosity and specific surface area of materials and improve their heat transfer, mass transfer, breathability, etc

- After granulating, the density of the material increases and its unit weight decreases, which is convenient for storage and shipment

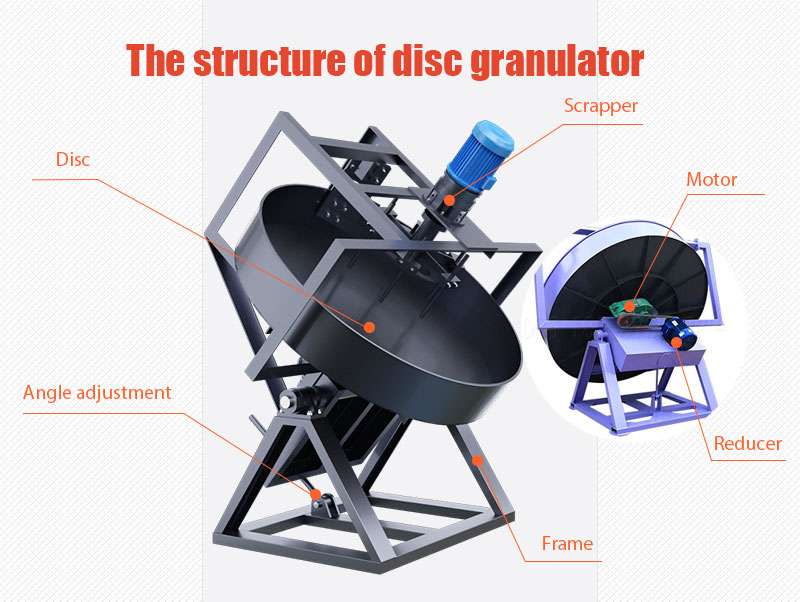

The structure of disc granulator

Disc granulator machine is composed of the disc, scraper, angle adjuster, motor, reducer, frame, base, etc. The following are the key components of the disc pelletizer that work together to facilitate the granulation process.

1. Granulating disc

The disc adopts an arc structure, installed horizontally on the rotating shaft. It is the platform for the granulation process and includes a spindle, two sets of roller bearings, and two shaft blocks. The disc bottom is reinforced with multiple heat-dissipating steel plates, which have high strength and good rigidity.

2. Scraper

The scraper system consists of a scraper and a scraper frame, and the scraper is installed on the top of the granulation disc. As the disc rotates, the scraper prevents excessive material build-up, promotes uniform mixing, and promotes particle formation.

3. Angle adjuster

Angle inclination adjuster that allows the operator to modify the angle at which the puck is positioned relative to the horizontal. By adjusting the angle 35-55°, the residence time of the material on the disc can be controlled, affecting the process of particle growth.

4. Driving part

The reducer and motor work in tandem to ensure that the disc rotates at the optimal speed for granulation. The reducer and the motor are driven by a flexible belt, which ensures a smooth start, low impact force, and longer service life of the equipment.

Why choose FTM Machinery disc granulators?

Disc pelletizers offer some outstanding advantages that make them popular choices for granulation processes in various industries.

- The granulator has a novel structure, lightweight, low height, and flexible process layout.

- The disc granulator adopts an overall arc structure, and the granulation rate can reach more than 95%.

- The inclination angle of the disc can be adjusted (35–55°). Angle spacers are used for flexible and convenient adjustment.

- 90% of the granule diameter is 3–6 mm. The effect of granulation is good, and there will be no big mud balls.

- The transmission gear, adopting high-frequency quenching treatment, has a long service life.

- It can be automatically graded according to the size of the particles and the discharged ball products are qualified.

- Brand new desilting design. The scraper device, composed of an unpowered combination scraper and corner cleaning scraper, can clean bottoms and edges, saving labor.

How does a disc granulator work?

Step 1 Send fine-grained mixture to the feeding area of the disc through the belt conveyor.

Step 2 Spray a proper amount of water from the top of the disk with a sprinkler. Due to the cohesive force of water, the bulk material becomes the cue ball.

Step 3 The material is lifted by the frictional force generated by the edge and bottom of the disk. The material rolls down when brought to a certain height.

Step 4 Cue balls of different sizes roll up and down with the disc, constantly rubbing and compacting, and grow to the prescribed size.

Step 5 Different particles are naturally graded. Small particles leave the discharge end, while large particles are concentrated at the discharge end and finally discharged through the edge of the plate.

How to improve the pelletizing rate of the disc granulator?

1 Control the water content of granules

Maintain the optimal moisture content for the material being granulated. Moisture is essential for binding particles together. Excessive moisture can lead to agglomeration or difficulties in granule formation.

2 Strictly control the quality of the powder

It is strictly forbidden to have iron blocks, stones, and wood blocks larger than 10 mm in raw material feeding and discharging.

3 Choose applicable nozzle of the pan granulator

The pan granulator generally adopts a B-type spherical screw or B1-type screw nozzle. Under the same pressure, the nozzle with the small orifice sprays a small density droplet; the nozzle with the large orifice sprays a large density droplet.

4 Change the scraper of the disc granulator

The granule will be even in size and beautiful if the scraper is good. The material of the blade must be 16M. There should be no gap between the two scrapers.

5 Operate the technique of the disc pelletizer

Carry out the technical training of the disc granulator to improve the technical quality and operation skills of the workers.

Customer cases of FTM Machinery disc granulator

FTM Machinery provides you with a variety of disc pelletizer equipment. You can choose any model you want, depending on your production conditions and capital budget.

8 TPH NPK fertilizer disc granulator in Russia

| Model | Φ2.2 m |

| Material | NPK fertilizer |

| Rotation speed | 14.25 r/min |

| Dimensions | 2.8×2.75×2.58 m |

| Equipment capacity | 4–8 t/h |

8 TPH disc granulator:Get the Latest Price

12 TPH gypsum disc granulator in Pakistan

| Model | Φ2.8 m |

| Material | Gypsum |

| Rotation speed | 11.21 r/min |

| Dimensions | 3.4×2.6×3.1 m |

| Equipment capacity | 12–16 t/h |

12 TPH disc granulator:Get the Latest Price

20 TPH coal ash disc granulator in Egypt

| Model | Φ3.6 m |

| Material | Coal ash |

| Rotation speed | 9.1 r/min |

| Dimensions | 4.3×3.1×4.0 m |

| Equipment capacity | 18–24 t/h |

20 TPH disc granulator:Get the Latest Price

In addition, if you encounter any problems or have any requirements when using disc granulators for granulation, FTM Machinery will be happy to solve them for you.

Frequently asked questions about disc granulators

1. What is generally the angle of inclination of the disc granulator?

- The angle of inclination adjustment device is in the position of the support of the pan pelletizer, which can be adjusted according to the size of the required particles.

- This angle refers to the angle at which the disc of the granulator is positioned about the horizontal plane. The suggested angle of inclination is between 40° and 50°.

2. Does the material need to be dried after granulation?

- Yes. In general, the material is added with a certain amount of water during the granulation process, which requires a dryer for drying to facilitate storage and transportation.

- If you're unsure whether drying is necessary, it's recommended to consult with FTM Machinery experts to determine the best approach.

3. What are the precautions for the disc granulator?

- a. Check whether the connection parts are firm and whether the bolts are loose before starting the machine.

- b. Pay attention to the rotation direction of the disk when starting up.

- c. The reducer must be filled with gear oil before it is used for the first time of production and it will be replaced every 4 months thereafter.

- d. The bearing shall be lubricated once per shift. The lubricating oil type is No.3 calcium base grease lubricating oil with a charge weight of 1/3–1/2 and it shall be replaced regularly.

Parameter

|

Specification

(m) |

Rotation speed

(r/min) |

Production capacity

(t/h) |

Motor

(kw) |

Adjustment range of obliquity

|

Dimensions

(m) |

Total weight

(t) |

|

Φ2.2

|

14.25

|

4-8

|

7.5

|

35-55

|

2.8×2.75×2.58

|

3.2

|

|

Φ2.5

|

11.81

|

5-10

|

7.5

|

35-55

|

3.2×2.3×3

|

3.6

|

|

Φ2.8

|

11.21

|

12-16

|

7.5

|

35-55

|

3.4×2.6×3.1

|

4.1

|

|

Φ3.0

|

11.3

|

15-18

|

11

|

35-55

|

3.7×2.7×3.3

|

4.8

|

|

Φ3.2

|

9.6

|

15-20

|

11

|

35-55

|

3.9×2.7×3.4

|

5.6

|

|

Φ3.6

|

9.1

|

18-24

|

15

|

35-55

|

4.3×3.1×4.0

|

7.2

|

|

Specification

(m) |

Rotation speed

(r/min) |

Production capacity

(t/h) |

Motor

(kw) |

|

Φ2.2

|

14.25

|

4-8

|

7.5

|

|

Φ2.5

|

11.81

|

5-10

|

7.5

|

|

Φ2.8

|

11.21

|

12-16

|

7.5

|

|

Φ3.0

|

11.3

|

15-18

|

11

|

|

Φ3.2

|

9.6

|

15-20

|

11

|

|

Φ3.6

|

9.1

|

18-24

|

15

|