What is a compound crusher?

A compound crusher, also called vertical compound sand maker, is a double-rotor primary impact crusher. The compound crusher is an ideal machine for crushing high-moisture and viscous materials, commonly used in small-scale crushing and sand production lines.

This crusher is a new type of fine crushing and coarse grinding product that FTM Machinery optimizes the main technical parameters on the basis of the PEL vertical compound crusher. It is used in mining, metallurgy, construction, and coal industries, especially for the production of clinker and aggregates in small and medium-sized cement plants.

Why choose FTM Machinery compound crushers?

The compound crusher combines the characteristics of the impact crusher and the hammer crusher and has many advantages.

- The compound crusher has primary and secondary crushing functions at the same time, with high crushing efficiency and reduced cost.

- Large crushing ratio, it can crush 100–240 mm materials into small particles smaller than 3–5 mm at one time.

- The hammer head and the impact plate gap can be adjusted to meet various granularity conditions.

- Adopting a grateless structure, even if the material contains a lot of mud, it is not easy to block.

- The long-life bearings are arranged horizontally, which can crush high-temperature materials such as cement clinker.

- The working noise is lower than 75 decibels (dB level), low noise, and less dust pollution.

- Wearing parts are made of high-hardness, high-toughness, multi-element alloy wear-resistant materials, and the service life is increased by 2–3 times.

- The screw rod or the hydraulic pressure opener is installed in the rear cavity, easy to change quick-wear parts.

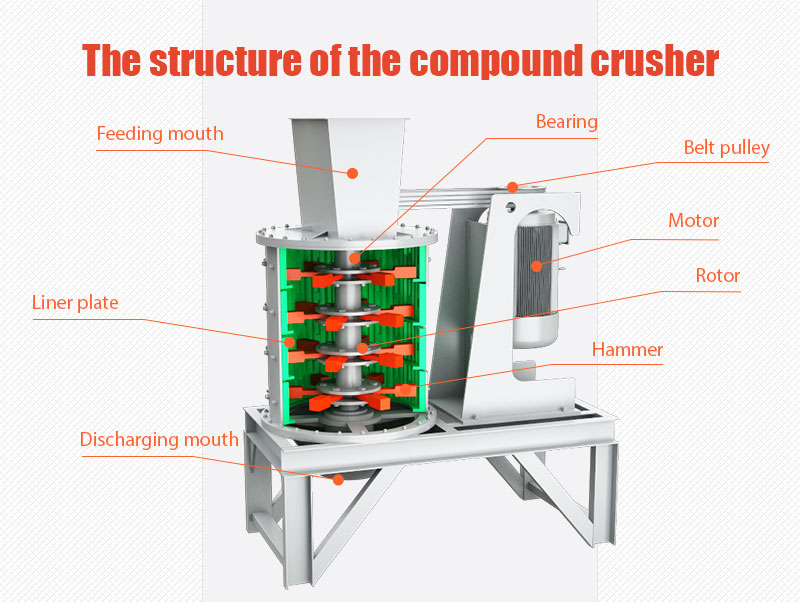

The structure of the compound crusher

The vertical compound crusher is mainly composed of the crushing system (rotor, bearing, liner, hammer), transmission system (motor, pulley), in-and-out mouths, and other parts. Among them, the crushing system is the easy-wearing component, which is mainly introduced for you.

1. Rotor

The rotor is a key part installed vertically in the crusher and is made of solid cast steel. The rotor circumference is equipped with hammers with adjustable clearance, responsible for high-speed rotation.

The rotor has a special structure that won't be worn once crushed. The speed and rotation direction of the rotor affect the crushing efficiency.

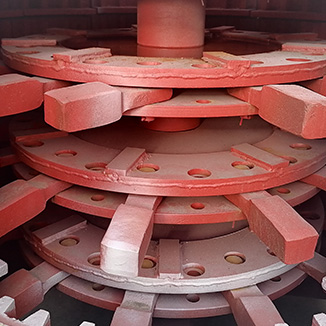

2. Hammer

The flat hammer is a vulnerable part of the crusher, installed on the rotor. They break the material by striking it repeatedly.

The hammer head is made of wear-resistant alloy steel or bimetal thermal compound material and the weight is generally between 9-36 kg.

3. Liner plate

The liner plate refers to the wear-resistant plate inside the crushing chamber, which plays the role of grinding materials and protecting the cylinder from wear.

The special casting and heat treatment process makes the liner have good impact resistance.

4. Bearing

The bearing assembly supports the rotation of the rotor and is critical to the smooth operation of the crusher.

Generally, double-row radial spherical roller bearings are selected, which have strong bearing capacity and good self-aligning performance.

How does a compound crusher work?

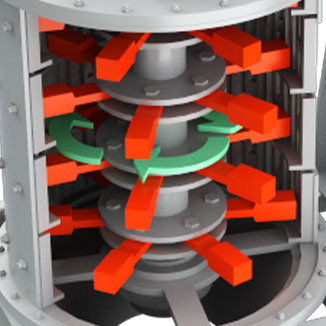

Working principle of compound crusher

Materials fall into the high-speed spinning impeller from the machine top, and under the action of high-speed centrifugal force, they bounce up with other surrounding umbrella-shaped materials at high speed and break.

After materials bounce, they repeatedly collide, rub, and crush in the eddy current between the impeller and the casing. Finally, they are discharged from the bottom of the barrel to form a closed circuit.

Customer case: Coal gangue compound crusher in Russia

Coal gangue is a kind of solid waste discharged in the process of coal mining and coal washing in coal mining plants. The accumulation of coal gangue not only pollutes the environment but also occupies a large amount of land area.

Russian customers used FTM Machinery compound crushers for processing, so the coal gangue could be utilized.

- Crushing material: Coal gangue

- Main equipment: 1750 compound crusher

- Capacity: 80–100 TPH

- Discharge particle size: ≤5 mm

- Product uses: Lightweight concrete, road construction, abandoned mine reclamation, fuel for power generation, etc.

Performance characteristics of coal gangue compound crusher

- 1The compound crusher is suitable for crushing coal gangue with high water content, which is more effective than other crushers.

- 2This crusher processes coal gangue, and it is not easy to appear the phenomenon of sticking to the inner wall.

- 3The vertical structure design reduces the footprint of the machine.

- 4The equipment can save energy by more than 40% and increase the output of coal gangue.

- 5The finished coal gangue has uniform particle size and excellent particle shape, which can meet the needs of customers.

Frequently asked questions about compound crushers

1. Vertical compound crusher VS sand making machine

- a. The working principle is different

- The compound crusher crushes the material by the impact of the blow bar and the impact plate, which is easy to cause wear. The sand-making machine crushes materials by the principle of "rock on rock" or "rock on iron", and the wear on the impact plate is almost small.

- b. Finished grain shape is different

- The finished product of the compound crusher has a uniform particle size and low over-crushing rate, which meets the construction use standards. The sand maker has a shaping effect and is more suitable for producing high-quality sand with a good grain shape.

- c. Feeding size and output are different

- The input size of the compound crusher is ≤240 mm and the output is 5–100 t/h. The input size of the sand-making machine is ≤55 mm and the output is 40–650 t/h.

- d. The price is different

- The price is affected by models, equipment manufacturers, manufacturers, etc., and there will be fluctuations. But in the current market, compared with the two crushers, the compound crusher is slightly lower.

2. How to troubleshoot common faults of compound crushers?

- a. Fault phenomenon: Fine granularity

- Reason: More hammerheads

- Solution: Reduce one or two layers of hammer head.

- b. Fault phenomenon: Coarse granularity

- Reason: Loose belt or low speed

- Solution: Tighten the belt and adjust the clearance of the impact frame.

- c. Fault phenomenon: The crusher body swings

- Reason: Unbalanced rotor centrifugal force

- Solution: Replace the hammer head with a new one, or adjust the weight of the push head.

3. Precautions for the operation of the compound crusher

- a. Before starting the machine, check whether the door of the machine is closed tightly. It is strictly forbidden to open the door during the operation.

- b. The crusher must be started when it is empty, and the material will be put in after it is in normal operation.

- c. The particle size of the material should be by the requirements of the feed size.

- d. If there is a failure during the operation of the machine, it should be stopped for inspection.

- e. Regularly add lubricant, and rotate bearing parts.

Parameter

| Specification | Capacity(t/h) | Power(kw) |

| 800 | 5-15 | 4P 30 |

| 1000 | 10-30 | 4P 55 |

| 1250 | 17-60 | 6P 132 |

| 1500 | 25-80 | 8P 160 |

| 1750 | 30-100 | 8P 200 |

| Specification | Capacity(t/h) | Power(kw) |

| 800 | 5-15 | 4P 30 |

| 1000 | 10-30 | 4P 55 |

| 1250 | 17-60 | 6P 132 |

| 1500 | 25-80 | 8P 160 |

| 1750 | 30-100 | 8P 200 |