Grinding is one of the most essential processes in mineral processing. Whether you're working with gold, iron, copper ores, or industrial materials like cement and gypsum, choosing the right grinding mill can significantly affect your productivity, energy use, and overall profits.

There are various types of mills used in the industry, and they differ in how they reduce particle size.

In this guide, we'll explore three major types of grinding mills:

- Ball Mill

- AG Mill (Autogenous Mill)

- SAG Mill (Semi-Autogenous Mill)

Definitions: What is a ball mill, AG mill, and SAG mill?

Ball mill

A ball mill is a horizontal rotating drum that uses steel or ceramic balls as grinding media. The balls are lifted and dropped to crush and grind the material inside the cylinder. Ball mills can be wet or dry, depending on whether water is added during the grinding process.

AG mill (Autogenous mill)

An AG mill (or autogenous mill) eliminates the need for grinding media. Instead, the ore itself acts as the grinding agent. These mills are best suited for moderately hard ores where the rock can break itself apart through impact and abrasion.

SAG mill (Semi-autogenous mill)

A SAG mill (short for Semi-Autogenous Grinding Mill) is a hybrid between a ball mill and an AG mill. It uses both the ore and a small percentage of added steel balls to improve grinding efficiency. SAG mills are typically used in large-scale mining operations for primary grinding.

Typical uses of grinding mills

Ball mills, AG mills, and SAG mills each offer unique advantages and are suited to specific working conditions in industrial mineral processing.

Ball Mill

Ball mills are commonly used in secondary grinding stages, following medium or fine crushing. They are widely used for fine grinding and regrinding circuits. The longer the mill runs, the finer the final product.

- Feed size: ≤25 mm

- Discharge size: 200 mesh

Typical applications include grinding the following materials:

- Cement clinker, slag, limestone, ceramics, silicates

- Non-metallic minerals such as talc, kaolin, quartz

- Fine grinding before flotation of metallic ores such as gold ore, iron ore, copper ore, lead-zinc ore

Small ball mills and large ball mills for sale Contact us now

AG Mill

AG mills are suitable for processing:

- Medium to hard ores with low clay content

- Materials that naturally generate a good grinding medium, such as iron ore and limestone

- Feed size: up to 300 mm

Advantages: AG mills can significantly simplify the crushing process by eliminating the need for medium and fine crushing stages. They are ideal for flowsheets that prioritize process simplicity.

When the ore conditions are suitable, AG mills offer better energy efficiency and lower operational costs than ball mills or SAG mills.

Autogenous mills for sale Contact us now

SAG Mill

SAG mills are the primary grinding equipment in most modern large-scale mining operations, especially suited for ores containing hard-to-grind particles, such as tough rock and pebbles.

- Feed size: up to 300 mm

- Often replaces secondary crushing and part of coarse grinding in traditional "three-stage crushing + ball milling" flowsheets

- Often combined with a ball mill to form the SAB (Semi-Autogenous + Ball Mill) circuit, this is the mainstream process for gold ore processing — particularly well-suited for medium to large-scale primary gold deposits containing medium to hard rock and sulfide minerals (such as vein-type and altered rock-type gold ores)

Semi-autogenous mills for sale Contact us now

How do these grinding mills work?

Grinding efficiency depends heavily on how each type of mill works.

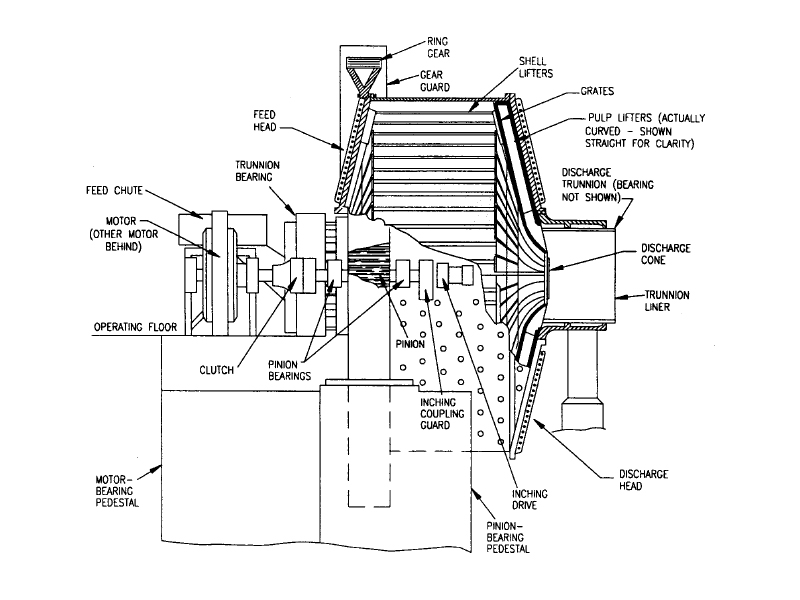

Ball mill working principle

When the drum rotates, the grinding media is lifted along the side of the shell and then dropped onto the material at the bottom. This process repeats continuously, generating strong impact and attrition forces that reduce the ore size.

Watch the video: Ball mill grinding in action

The material enters continuously through the feeding end and is gradually crushed by the repeated impact and grinding of the steel balls.

The particles that meet the particle size requirements are discharged through the grating plate or overflow weir at the discharging end, and the coarse particles continue to be ground.

AG mill working principle

As the mill rotates, larger rocks are lifted and dropped, crushing smaller particles below. Meanwhile, friction and impact between ore fragments further break down the material.

Watch the video: AG mill operating with self-grinding ore

The raw ore—often a mix of coarse and fine particles—is fed directly into the drum. The lifting liners inside the mill help raise and drop the larger pieces for grinding action. Fine particles are discharged through the outlet, while oversized material remains in the mill for continued processing.

SAG mill working principle

SAG mill uses the ore itself for primary grinding, just like an AG mill, but also includes a small percentage of steel balls (typically 3%–15% of the mill volume) to improve performance.

This setup helps crush "critical size particles"—those that are too hard to break down naturally but too big to be discharged. By adding grinding media, SAG mills maintain throughput and enhance grind quality.

Watch the video: SAG mill crushing hard-to-grind particles

The ore and grinding balls are loaded together. As the mill rotates, ore-on-ore and ball-on-ore interactions occur, creating a dual-action grinding environment that maximizes efficiency.

Core structural differences

Understanding the internal structure of different types of mills, especially SAG mills, ball mills and AG mills, is essential to choosing the right grinding solution.

1. Drum size

| Mill type | Drum dimensions | Purpose |

| Ball mill | Long and narrow (high length-to-diameter ratio) | Ideal for fine grinding, where longer retention time enhances grindability |

| AG mill / SAG mill | Short and wide (large diameter) | Allows for handling large feed sizes, suitable for coarse grinding |

Ball mills are compact in diameter but longer in length. This elongated design supports gradual reduction in particle size during continuous ball mill grinding.

In contrast, SAG mills and AG mills are engineered with massive diameters—often over 12 meters—to lift large ore chunks to greater heights for impactful collisions.

2. Liner materials

Ball mill liners

Ball mills use a variety of liner types to suit different grinding conditions and operating environments.

- High manganese steel liners: Known for high hardness and good wear resistance, ideal for grinding hard and abrasive ores.

- Rubber liners: Best suited for wet grinding, noise reduction, and corrosive environments. However, they may not perform well under high impact or high-temperature conditions.

- Alumina (Ceramic) liners: Designed for ultrafine grinding. These liners are highly wear-resistant and chemically inert, ensuring product purity and minimal contamination.

AG/SAG mill liners

AG and SAG mills typically use liners made from high chrome iron (HCI) or alloy steel. These materials offer exceptional hardness and abrasion resistance, capable of withstanding the high-impact forces and severe wear caused by large ore chunks.

A key structural feature of SAG and AG mill liners is the presence of tall, robust lifters. These lifters are critical components of the liner system, designed to lift and cascade the ore (and grinding media in SAG mills) during rotation to maximize grinding efficiency.

3. Drive system

Ball mills, AG mills, and SAG mills all rely on high-power electric motors to drive the rotating drum. However, their transmission structures and power requirements differ significantly.

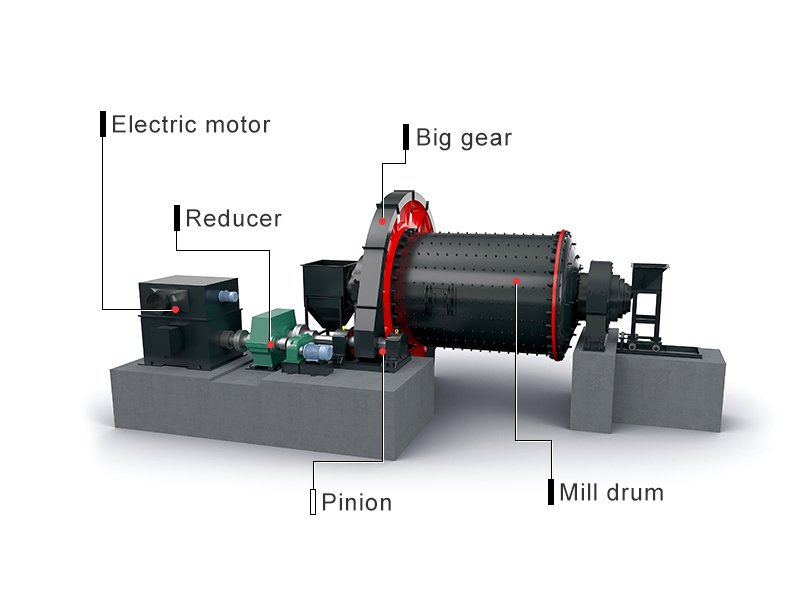

Ball mill drive system

Ball mill transmission typically uses a gear drive configuration, where the electric motor powers the drum through a step-down mechanism.

Electric motor → Reducer → Pinion → Girth gear → Mill drum

- This setup is common in medium-sized ball mills and small ball mills.

- The power of small and medium-sized ball mills ranges from hundreds of kilowatts to several megawatts (MW), and large multi-bin ball mills can reach more than 10 MW (such as large raw material mills in the cement industry).

AG/SAG mill drive systems

There are two primary drive configurations used in autogenous (AG) mills and semi-autogenous (SAG) mills:

- Gearless ring motor (GRM): The most widely adopted solution. The motor rotor is directly mounted onto the mill shell, eliminating the need for gear transmission. This system delivers extremely high starting torque and improved mechanical simplicity.

- Dual pinion drive: High-power variable frequency motors (VFDs) drive the ring gear through two independent pinion gear sets. This configuration distributes load and enhances system reliability under heavy-duty conditions.

The power requirements for autogenous (AG) and semi-autogenous (SAG) mills are generally greater than 10 MW, with large-scale projects typically equipped with over 20 MW (the maximum has exceeded 40 MW). Variable Frequency Drives (VFDs) and dedicated braking systems are required to handle high impact loads and ensure safe shutdown.

Note: Grinding mill drives account for over 50% of total energy consumption in a mineral processing plant, making them one of the most critical energy-intensive components.

Summary: Comparison of the three grinding mills

| Feature | Ball mill | AG mill | SAG mill |

| Grinding media | Steel balls / Ceramic balls | Ore itself as media | Ore + Steel balls |

| Grinding mechanism | Impact + attrition | Primarily high-drop impact | High-drop impact + steel ball impact |

| Feed / discharge size | Feed ≤25 mm, Discharge 0.074–0.89 mm | Feed up to 300 mm, Discharge 0.5–5 mm | Feed up to 250 mm, Discharge 1–3 mm |

| Energy consumption | Medium | Low | High |

| Equipment cost | Low | Medium–high | High |

| Maintenance complexity | Low | Medium | High |

| Typical applications | Cement, coal powder, ceramics | Medium-hard homogeneous ores | Gold, copper, large-scale mining |

Which mill is right for You?

- Choose a Ball Mill if the feed size is small (≤25 mm), the required product size is 0.074–0.089 mm, or the process must accommodate a wide range of ore types.

- Choose an AG Mill if your ore is suitable for autogenous grinding (medium-hard, low clay content) and you want to minimize operating costs (no media consumption).

- Choose a SAG Mill if you're processing complex or hard ores and are willing to invest more upfront to simplify the overall flowsheet.

Need help choosing the right mill?

Our experts at FTM Machinery are here to help you find the best-fit grinding solution, optimize your mill sizing, and support you from design to production. Let's talk about your project. Consult our engineer