Ball mills are the key equipment for grinding after the material is crushed. They are the most commonly used grinding machines in metal beneficiation, building materials, glass ceramics, and other industries.

According to different ore discharge methods, ball mill types can be divided into the grid ball mill and the overflow ball mill. How to choose the right ball mill type? This blog introduces the differences, prices, and options of these two ball mills in detail.

Differences between grid and overflow ball mill

In addition to the similar structure and working principle, the grid-type ball mill (the lattice-type) and the overflow-type ball mill are quite different.

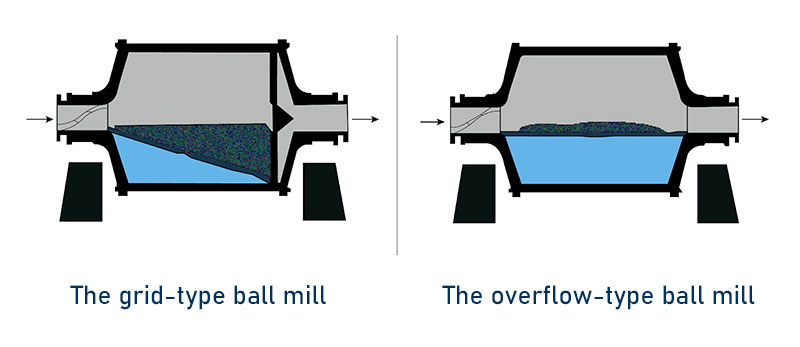

1. Different ore discharge structure

The ore discharge side of the grid-type ball mill is equipped with a grid plate, and there are many discharge holes on the grid plate. The ground pulp passes through the grating plate and is lifted by the lifting plate into the discharge spiral barrel, so that the material is discharged from the mill.

The overflow ball mill does not have a grid. But on the inner surface of the hollow journal bushing at the discharge end, there is the spiral blade with a spiral direction opposite to the mill rotation direction. The purpose is to prevent water balls or coarse mineral lumps from being discharged together with the slurry.

2. Different discharge way

The grid-type ball mill discharges the material through the sieve plate under pressure, which is a forced ore discharge. This is also the reason for the name grid ball mill.

The overflow-type ball mill overflows from the discharge pipe when the pulp in the cylinder reaches a certain height, which is a passive ore discharge. This is also the reason for the name overflow ball mill.

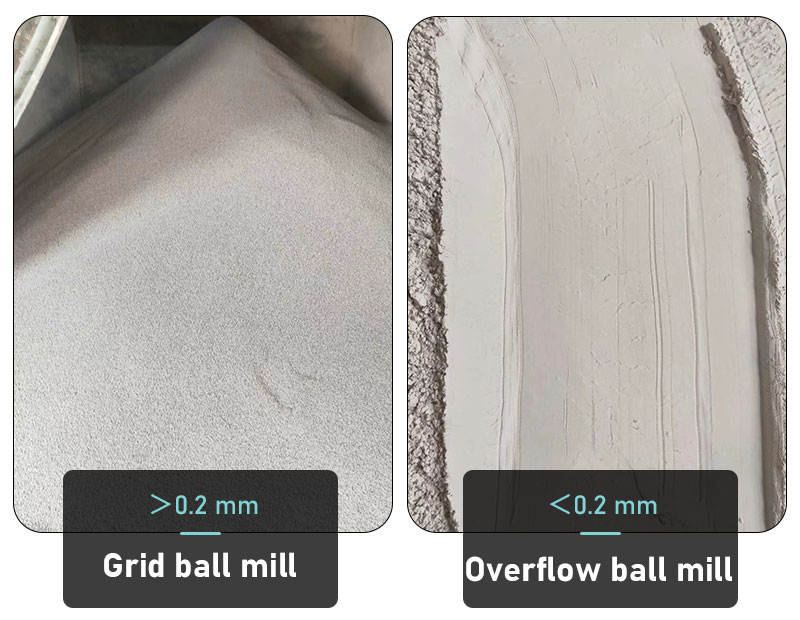

3. Different discharge granularity

In the grid ball mill, the upper limit of the particle size of grinding products is 0.2-0.3 mm, and it is often used in the first stage of the two-stage grinding process. It often forms a closed loop with a spiral classifier.

In the overflow ball mill, the particle size of grinding products is generally less than 0.2 mm, and it is often used in the second stage of grinding. It is suitable for concentrate regrinding operations and can obtain finer qualified products.

4. Different production capacity

Due to the fast discharge speed of the grid ball mill, the grinding time of the material in the cylinder is relatively short. The production capacity is high, but the product particle size is coarse.

Compared with the grid ball mill of the same specification, the productivity of the overflow ball mill is about 10%-15% lower, but the grinding product is finer.

5. Different over-grinding degree

The unique grid plate of the grid ball mill and the lifting bucket in the fan-shaped room realize low-level forced ore discharge. The finely ground ore particles stay in the ball mill for a short time and are discharged in time, which reduces the over-crushing phenomenon of gravel.

The overflow type ball mill belongs to the non-forced high material level ore discharge, and the discharge speed is slow. The mineral material stays in the machine for a long time, so its over-grinding phenomenon is serious.

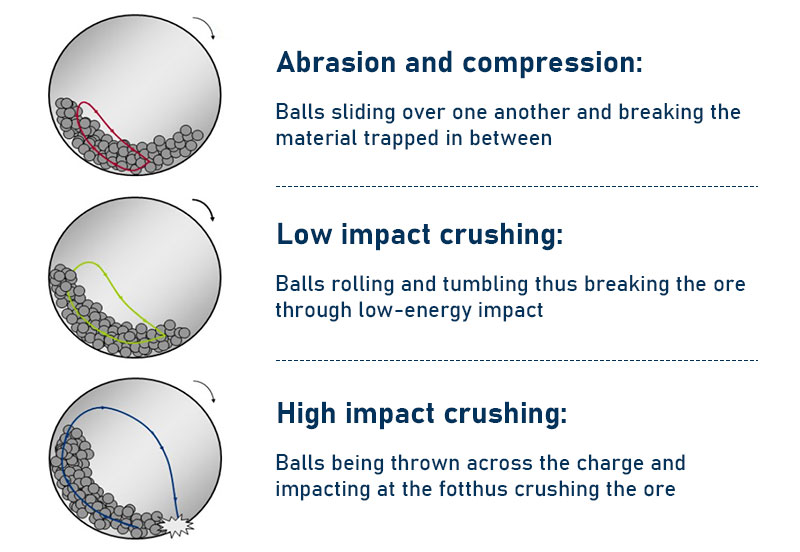

6. Different motion state of the steel ball

The speed of the grid-type ball mill is high, and the steel balls are dropped. Relatively low slurry surface, the ball has a greater drop height. The main force is impact, supplemented by grinding, and the grinding effect is better.

The speed of the overflow ball mill is low, and the steel balls rise to a certain height and then fall continuously. The main force is grinding, supplemented by impact.

7. Different maintenance difficulty

Due to the structure of the ore-discharging plate of the grid-type ball mill, the gap between the grate seam and the compartment plate is easily blocked by the ore slurry. This increases the difficulty of maintenance and inconvenient maintenance.

In contrast, the overflow ball mill has a simple structure and easy maintenance because it has no grid plate configuration.

Read ball mill repair: How to Solve Ball Mill Problems?

The price of ball mills

FTM Machinery is a well-known ball mill manufacturer, with a wide range of grid and overflow ball mill models. However, each model corresponds to different parameters such as output, power, cylinder speed, ball loading, feed particle size, and discharge particle size. Know the Model of Ball Mills.

Different types of ball mills have different prices. Generally speaking, grid ball mills of the same specification are heavier and more expensive than overflow ball mills. Users can make a reasonable choice according to their own needs!

Grid and overflow ball mills: Get the Price and Model

How to choose a ball mill?

Grid and overflow ball mills each have unique features and applications that make them popular choices for different grinding requirements. When buying a ball mill, how to choose between the two ball mills? FTM Machinery makes the summary for you:

In the following situations, it is better to choose a grid-type ball mill:

- When it is necessary to grind the material into coarse products (about 48-65 mesh);

- When performing two-stage grinding, the first stage uses a grid ball mill;

- When the production scale is large and the capacity requirements are large;

- When the requirements for the discharge fineness are not high;

- When the material grinding effect is required to be good;

- When the budget to buy a ball mill is sufficient.

In the following situations, it is better to choose an overflow-type ball mill:

- When it is necessary to grind the material into fine products (about 150-200 mesh);

- When performing two-stage grinding, the second stage uses an overflow ball mill;

- When the production scale of the mineral processing plant is small;

- When coarse concentrate regrinding is required;

- When it is convenient to check and maintain the machine.

In short, users should clarify the specific production requirements of the mineral processing plants to choose the most suitable type of ball mill. You can also contact us, ball mills with an output of 0.65-615 tons per hour are available.