To make the finished cement product, cement manufacture involves two main steps: manufacture of clinker followed by fine grinding of the cement clinker with gypsum and other cement grinding additives like slag, natural pozzolans.

The latter step is carried out in the cement grinding plant.

A cement grinding plant, more commonly referred to as a clinker grinding unit or finish grinding plant, is an individual grinding plant in the finished cement production.

Integrated cement manufacturing plants perform both steps, whereas cement grinding plants can grind clinker along with desired additives to make cement elsewhere.

You may wonder why the cement grinding plant is built elsewhere.

Firstly, the cement clinker is easier and cheaper to store than finished cement. If the integrated plant is far away from the urban areas where the cement is consumed, the cement quality might deteriorate because it is not easy to preserve.

Secondly, lower the transportation costs. Most of the mixing materials are waste slag produced in the city. It will increase transportation costs if they are delivered into the cement plant built near the mining area, made into cement, and then transported to the city.

Last but not least, limited budget. Some cement manufactures could not afford clinker-making machines like limestone crushers, coal mills, cement kilns, cement coolers. Some cement manufactures can't afford cement raw materials that are not available locally. Naturally, they will build a cement grinding plant to make cement by processing clinker purchased from other places.

It is for these reasons that the market for cement grinding stations has grown.

Before investing in a cement grinding unit without knowing what cement machines to equip, learn cement production equipment first.

Cement grinding circuits

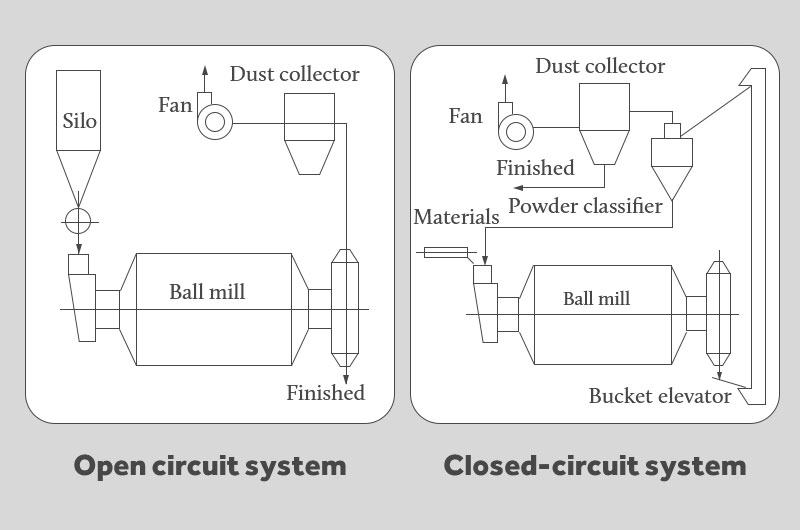

There are two types of ball mill (also called cement mill) operation systems, a closed-circuit system, and an open circuit system. We use the closed-circuit system as the standard because it is more energy-efficient and can grind different types of cement.

In an open circuit system, the material only passes through the mill once without classification and recycling oversize lumps. To ensure that the desired fineness of the products is achieved, open circuit mills are often adjusted to over-grind, and when particles are ground to a size finer than necessary, energy is wasted.

In a closed-circuit system, coarse particles are separated from the finer product and return for further grinding, making over-grinding unnecessary. What's more, the finished cement has a uniform particle size.

Equipment in cement grinding plant

Machines needed in cement grinding plant are cement mill, cement classifier, cement packing machine, dust collector, bucket elevator, etc.

Cement mill

The ball mills are still the most widely used cement mills. Clinker and 3–5% gypsum together with other additives, if necessary, are ground to extreme fineness in the it.

Cement particles average about 15 μm in diameter and approximately 85–95% of cement particles are smaller than 45 μm in diameter. Usually, the size of feeding materials is within 15 mm. If the clinker provided by customers is too coarse, crushers will be equipped accordingly.

The cement mill is a big consumer of electricity, so in order to reduce power consumption, FTM Machinery adopted various methods to save power:

- • Replace small ball mills with big ones

- • Install roller press to reduce the particle size of the material before entering the ball mills.

- • Load cement grinding balls reasonably.

- • Add an appropriate amount of cement grinding aid.

- • Reasonably design the water spray system inside the cement mill.

Cement classifier

The essential equipment of a closed-circuit grinding system is a cement classifier, also known as a cement separator. The function of it is to select the required cement powder in time and send the much coarse cement powder back to the grinding mill for regrinding, making sure the uniform particle size.

What's more, it selects fine particles materials in time, avoiding the occurrence of material condensation, adhesion to the grinding body, reducing the over-pulverization of materials in the grinding mill.

Dust collector

The dust collector in the cement grinding plant has two main functions

1) Collect raw materials powder or finished cement products;

2) Filter out the dust, ensure that the gas emission is clean and up to standard, and ensure the safety of production equipment and the health of workers.

Therefore, the cement grinding unit designed by FTM Machinery is equipped with a dust collector with high dust removal efficiency and good sealing effect, improving working conditions and preventing air pollution. Commonly used dust collectors are electrostatic precipitators and pulse bag dust collectors.

Cement packing machine

The cement packing machine is used to complete the automatic packaging of cement and is an essential machine for cement production. FTM Machinery cement packers can load 1,200–3,000bags of cement per hour, which improves work efficiency and saves labor costs. It is a star in the medium-size cement plants and mini cement plants.

Tips: It is also used for powdery materials with good liquidity, such as fly ash and cement additives.

What can FTM Machinery provide?

Choosing a reliable supplier is halfway to a robust cement grinding plant. And FTM Machinery is the right supplier you are looking for.

- 1.FTM Machinery can provide a custom-design solution to cement manufacturing for every client.

- 2.FTM Machinery can provide perfect after-sales service, which covers equipment installation, operation, production, and maintenance. And we will send technicians for guidance and training until customers are satisfied.

- 3.FTM Machinery can provide cement grinding plants at factory prices.

- 4.Cement production starts up in three to six months.

- 5.All types of cement are possible.

How much does a cement grinding plant cost?

The cement grinding plant cost depends on changing factors like scale, location, labor, raw materials, etc. Therefore, it's impossible to nail down a perfectly accurate, one-size-fits-all answer.

As a cement grinding plant manufacturer, we'd like to lower customers' cost with cheaper and more reliable cement machines. Take a 15 TPH cement grinding station as an example, the recommended equipment and prices are as follows:

| Machines | Feeder machine | Cement mil | Dust collector | Classifier | Bucket elevator | Packing machine |

| Capacity: 15t/h | GZD-650-2300 | φ2.2×13 | ppcs96-4 | KMS-Ⅰ | NE100x25m | BHYW6C |

| Price($) | ≥1,000 | ≥7,800 | ≥3,000 | / | ≥1,000 | / |

Interested in the prices of different output cement grinding plant? Yes, I'm interested.

Price of cement clinker and finished cement

Clinker prices and cement prices are slightly different in different countries and regions. Given that China is a major cement producer and a major cement consumer, China's cement clinker prices and cement prices are selected as references.

| Types of cement/clinker | Ordinary Portland (P.O42.5) | Composite silicate (P.C32.5) | Portland slag silicate (P.S.A32.5) |

| Cement clinker | ¥360.00/t | ¥315.00/t | ¥175.00/t |

| Finished cement | ¥657.00/t | ¥560.00/t | ¥430.00/t |

Source: https://s.1688.com

Customer case—Cement grinding plant in the United Arab Emirates

Production capacity: 300,000 tons/year

Customer feedback: The customer purchased the whole set of cement production line equipment from Fote by recommendation. He said that the production line not only improved the overall output but had convenient maintenance of the entire production line without excessive worker operation and cost-saving.