As the world's demand for copper continues to grow, the resources of primary copper sulfide ore that are easy to mine and beneficiate have gradually decreased. It's urgent to explore and utilize copper oxide ore resources to mitigate the shortage of copper resources. The more you know about the copper oxide ore, the bigger chance of choosing a suitable beneficiation method, which is of great significance for improving the copper recovery rate.

Characteristics and floatability of main copper oxide ores

| Mineral names | Chemical formula | Copper content | Specific gravity | Hardness | Color | Flotability |

| Malachite | Cu2CO3(OH)3 | 57.5 | 5 | 3.5-4 | emerald green | Good flotability. |

| Azurite | Cu3(CO3)2(OH)2 | 55.5 | 3.8 | 3.5-4 | dark blue | The same as above |

| Chrysocolla | Cu2–xAlx{H2-xSi2O5)(OH)4•nH2O (x<1) | 36.1 | 2.1 | 2-4 | green | Strong surface hydrophilicity. Poor flotability. |

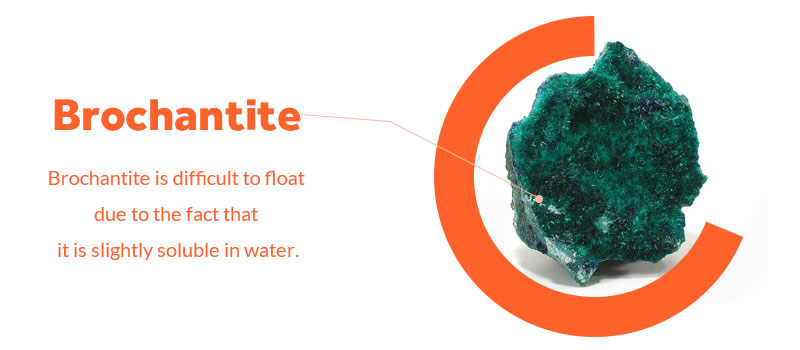

| Brochantite | Cu4SO4(OH)6 | 26.2 | 3.9 | 3.5-4 | green | Slightly soluble in water. Poor flotability. |

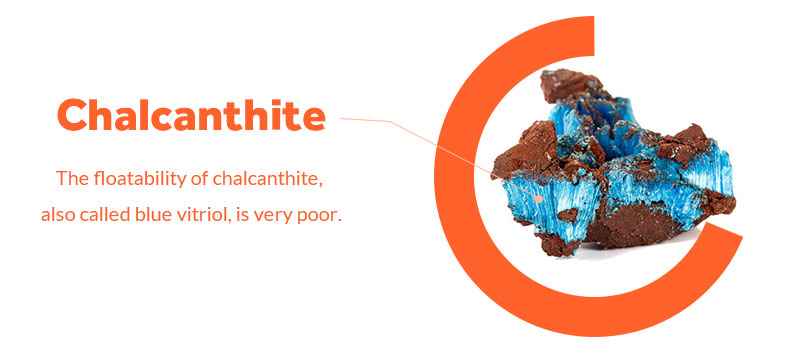

| Chalcanthite | CuSO4·5H2O | 25.5 | 3.3 | 2.5 | blue | Soluble, difficult to float |

| Cuprite | Cu2O | 88.8 | 6 | 3.5-4 | light red | Same flotability as malachite |

Copper oxide ores are mainly malachite and azurite, followed by chrysocolla and cuprite, copper sulfate and other soluble salts of copper.

Malachite Cu2CO3(OH)2

Malachite ore can be beneficiated by sulfurization floatation (vulcanization flotation). First, the surface of malachite ores is pre-sulfurized with sulfides such as sodium sulfide and ammonium sulfide, and then floated with collectors such as xanthate. If pre-vulcanization is not carried out, xanthate with no less than 5 ~ 6 carbon can also be used for flotation at a high dosage.

The direct flotation method is also suitable. That means floating malachite ores directly by using fatty acids (oleic acid, palmitic acid, etc.) as collectors. Flotation with fatty acid (salt) as a collector is only suitable for copper oxide ore with a siliceous gangue. If the gangue minerals of it contain a lot of carbonate and iron-manganese, the separation index will drop sharply.

The amine flotation method can also be used for malachite.

Azurite Cu3(CO3)2(OH)2

The flotation conditions of azurite are basically the same as malachite. When using fatty acids and their salts to float azurite, the flotation effect is better than that of malachite; when applying sulfidation flotation, azurite requires a longer vulcanization time.

Chrysocolla Cu2–xAlx{H2-xSi2O5)(OH)4•nH2O (x<1)

Chrysocolla, also called silicon malachite, has a strong surface hydrophilicity. It is difficult to beneficiate Chrysocolla because it is not easy to be vulcanized. When applying the vulcanization flotation method with Xanthate as a collector, its PH value and good activation need to be controlled strictly.

Brochantite Cu4SO4(OH)6

Brochantite is a mineral that is slightly soluble in water and is difficult to float. Generally, it is lost in tailings.

Chalcanthite CuSO4·5H2O

Chalcanthite, also called blue vitriol, is a soluble mineral. It is easily soluble in the slurry during flotation. The dissolution of it will increase the concentration of copper ions in the slurry, destroy the selectivity of the flotation process, and increase the consumption of reagents.

Factors affecting the beneficiability of copper oxide ore

The beneficiability (separability) of copper oxide ores is closely related to the types of copper oxide ore, gangue minerals, the symbiosis relationship between minerals and gangue, and the mud content.

Characteristics and beneficiability of different copper oxide ores

According to the different copper oxide minerals contained in the ores, copper oxide ores can be divided into seven types, and the separability of different copper oxide ores varies greatly.

Malachite type copper oxide ore

Its main mineral is malachite, and the content of other minerals is low. It is an easy-to-beneficiate ore and can be separated by sulfidation flotation.

Chrysocolla type copper oxide ore

The main mineral of it is chrysocolla. It is a refractory ore and can be separated by the chemical beneficiation method.

Cuprite type copper oxide ore

Cuprite-type copper oxide ore is dominated by cuprite and malachite, with high copper grade. No matter what type of gangue, it can be processed by flotation.

Brochantite type copper oxide ore.

Brochantite type copper oxide ore is dominated by copper alum minerals. It is a middle-difficult-to-beneficiate copper oxide ore. Flotation and chemical beneficiation can be used to recover copper. And the combined method shall be used if the gangue mineral is carbonate.

Native copper oxide ore

The mineral composition of it is mainly natural copper, cuprite, and malachite, with a small amount of azurite, black copper ore and combined copper ore, and a few secondary sulfides such as chalcocite and bornite. The gangue minerals are mainly limonite, silicate minerals, and carbonate minerals. It is an easy-to-beneficiate ore. The flotation method is commonly used to separate copper.

Combined type copper oxide ore.

Combined copper oxide minerals are wrapped by limonite or mud in very fine granular form. If the gangue mineral is silicate, it is difficult to beneficiate. If it is carbonate, it is more difficult to beneficiate. Commonly used beneficiation methods include chemical beneficiation and segregation-flotation method.

Mixed type copper oxide ore.

There are copper oxides and copper sulfides in the mixed-type copper oxide ore. The composition is complex and the particle size is slightly coarse. If the gangue is silicate, it can be treated by flotation-chemical beneficiation method.

Free copper oxide and bonded copper oxide

Free copper oxide minerals are copper oxide minerals that exist in independent forms. They can all be dissolved in the cyanide solution. The copper contained in it is free copper oxide and can be beneficiated easily.

While the copper in the bonded copper oxide minerals is often combined with the oxides of elements such as silicon, aluminum, calcium, magnesium, and manganese to form an aggregate that is difficult to dissociate into copper ion monomers and has low beneficiability.

The copper in the bonded copper oxide minerals is called bonded copper, and its percentage in the total amount of copper contained in the bound copper oxide mineral is called binding ratio, and its calculation formula is:

Binding ration= (bonded copper oxide amount / total copper oxide amount) × 100%

There are three ways to combine copper oxide and gangue: (1) It is mechanically dispersed in the gangue to become finely dispersed inclusions. (2) Become an isomorphism in a chemical way. (3) Become adsorbed impurities.

The influence of the gangue minerals on the beneficiability

The main gangue minerals of copper oxide ore are dolomite, quartz, calcite, clay, and limonite. Gangue types have a great impact on the floatability of copper oxide ore. Copper oxide ore containing siliceous gangue is easy to separate; copper oxide ore containing silicate gangue is difficult to separate; copper oxide ore containing iron hydroxide and clay sludge is extremely difficult to select.