After the four-month proposal of cobalt-free batteries, Tesla finally faced reality and bought cobalt again.

According to the Financial Times, Tesla bought cobalt from Glencore, which it plans to use in its Shanghai and Berlin plants.

You can't help but wonder what is cobalt?

Cobalt (Co) is a silver-white ferromagnetic metal. With its 27 protons, cobalt is sandwiched between iron and nickel in the middle portion of the periodic table.

Why Cobalt

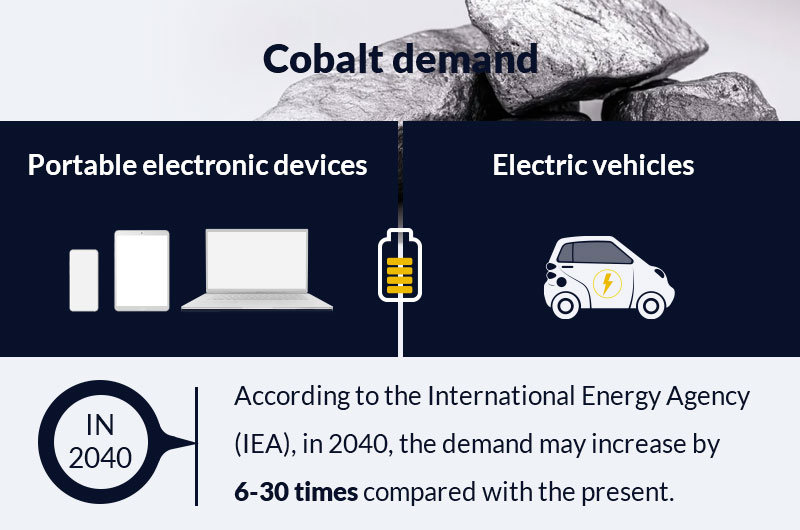

Cobalt is one of the core

materials of lithium-ion batteries. Lithium cobalt oxide battery technology is

now quite mature. In addition to being widely used in consumer-grade batteries

such as mobile phones and notebook computers, electric vehicles are the top

priority of lithium battery applications.

And cobalt is irreplaceable. In order to solve the long-standing difficulties of EV range anxiety and long charging time, lithium battery cathodes mostly use cobalt + lithium + nickel ternary polymers, such as nickel cobalt lithium manganate or nickel cobalt lithium aluminate.

The boom in EVs has spurred a surge in cobalt demand. According to the International Energy Agency (IEA), in 2040, the demand may increase by 6-30 times compared with the present.

Cobalt mine production and reserves

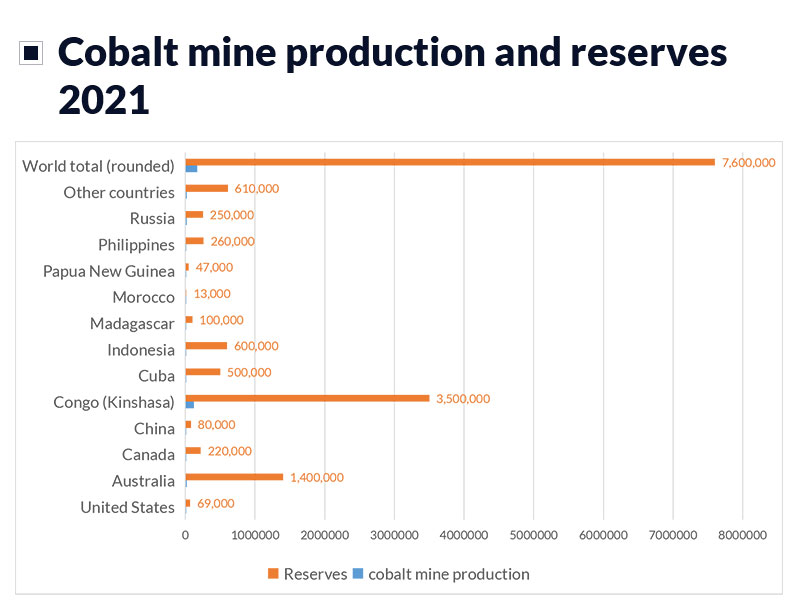

The surge in cobalt demand has raised concerns: Is our earth rich in cobalt? Can the annual cobalt production meet the demand?

Unfortunately, global cobalt resources are uneven, and world cobalt mine production is scarce. According to preliminary data released by the United States Geological Survey (USGS), global cobalt production in 2021 is about 170,000 tons and is in the hands of a few companies.

The DRC (Congo) is home to more than 50% of the world's cobalt reserves. The rest are in a handful of countries including Australia, Cuba, Zambia, Philippine, Canada, and Russia.

Congo supplies more than 70% of the world's cobalt, ranking first.

China is the largest cobalt refining and consuming country, accounting for 67% and 52%, while the output of cobalt is only about 1%.

Cobalt mining and processing

In nature, cobalt is mostly associated with minerals such as copper, nickel, and iron. Basically, there is no independent cobalt deposit. As a result, cobalt is primarily a by-product of copper and nickel extraction.

Given that Congo is the biggest cobalt supplier, I will briefly share several efficient cobalt processing methods widely used in the cobalt mines located in the Katanga copper-cobalt ore belt as an example.

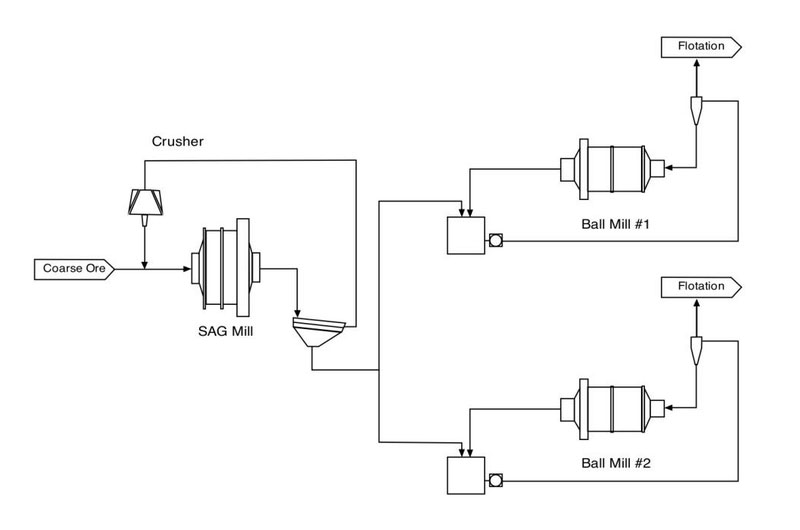

Crushing process

Severe sliming is a distinctive feature of copper oxide ore. The local rainy season (November to March) has heavy rainfall. That makes the ore high in water content and more viscous.

Considering factors such as ore properties, natural conditions, and production stability, in recent years, the crushing process of newly built concentrators in Congo (DRC) generally adopts the Semi-Autogenous Ball Mill Crushing Circuit (SABC).

- Crusher: Jaw crusher, Cone crusher

- SAG mill: Ball mill

Advantages:

- 1.Only one section of coarse crushing is required, minimizing the crushing stages. Shorter flowchart, less equipment. And that means less blockage of equipment.

- 2.With less equipment, the cobalt processing plant occupies a smaller area, reducing the cost of land acquisition.

- 3.Simple operation requires fewer workers, lowering labor costs.

At present, this crushing process is widely used in the new cobalt beneficiation plants in Congo (DRC).

Cobalt extraction process

The Katanga copper-cobalt ore belt in Congo (DRC), with a length of 300km and a width of 100-150km, runs from Kolwezi in the northwest to Lubumbashi in the southeast to the Zambian border.

The cobalt mines of this belt are quite different in terms of carbon content, mud content, oxidation rate, copper and cobalt grade, and main gangue composition.

To reasonably develop and utilize copper-cobalt ore resources and improve the metal recovery rate, it is necessary to continuously improve the beneficiation process. The typical sorting processes used in the recent large-scale mining projects mainly include the following.

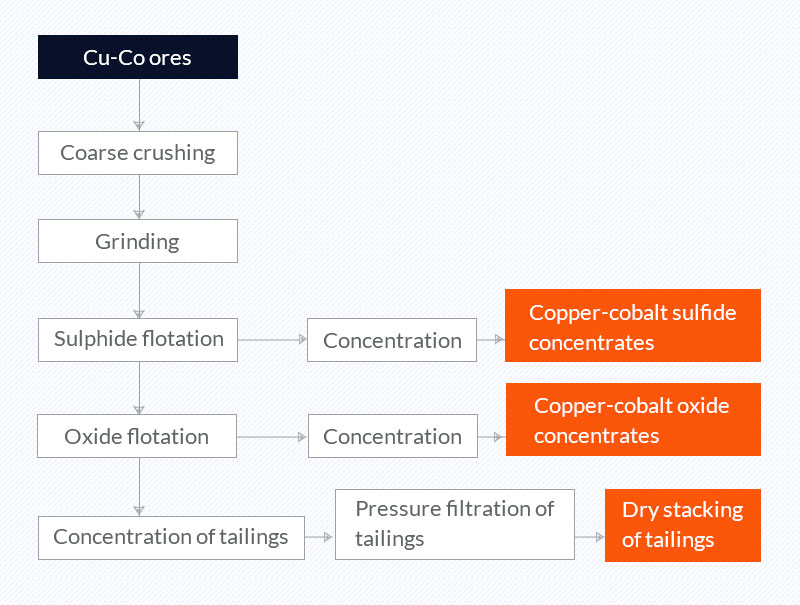

1. cobalt processing flowchart: single flotation of sulfur before oxygen

- Flotation equipment: Flotation machine

- Concentration equipment: High Efficiency Concentrator

- Flotation reagent: Sodium Silicate, Sodium Hydrosulfide, Bxanthate, Pentaxanthate and Foaming Agent

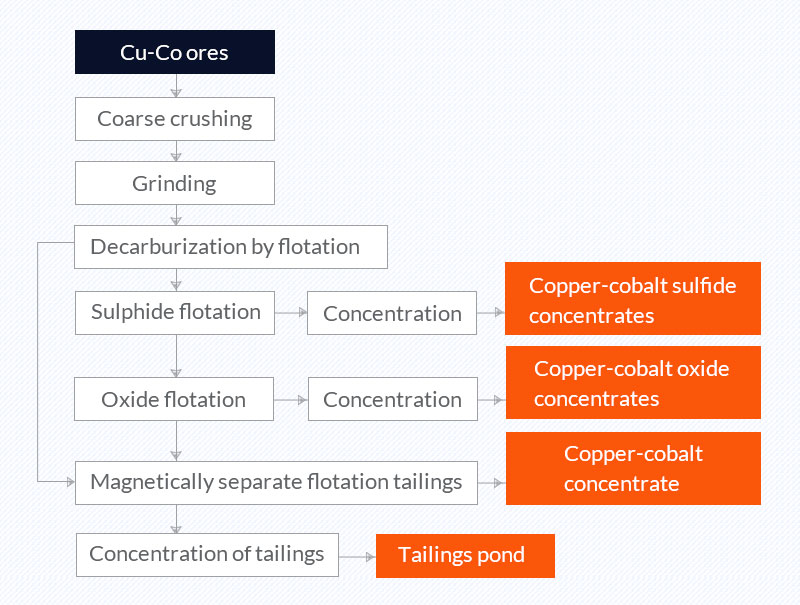

2. cobalt processing flowchart: dicarbon-flotation of sulfur before oxygen-flotation tail magnetic separation

- Desliming equipment: Double spiral washing machine or cylinder washing machine

- Flotation equipment: Flotation machine

- Magnetic separation equipment: Magnetic separator

- Concentration equipment: High Efficiency Concentrator

- Flotation reagents: The flotation reagents for sulfide ore are MIBC, NaHS, and xanthate; the reagents for treating oxidized ores and mixed ores include MIBC, NaHS, ammonium sulfate, ethionine, amyl xanthate, and CMC.

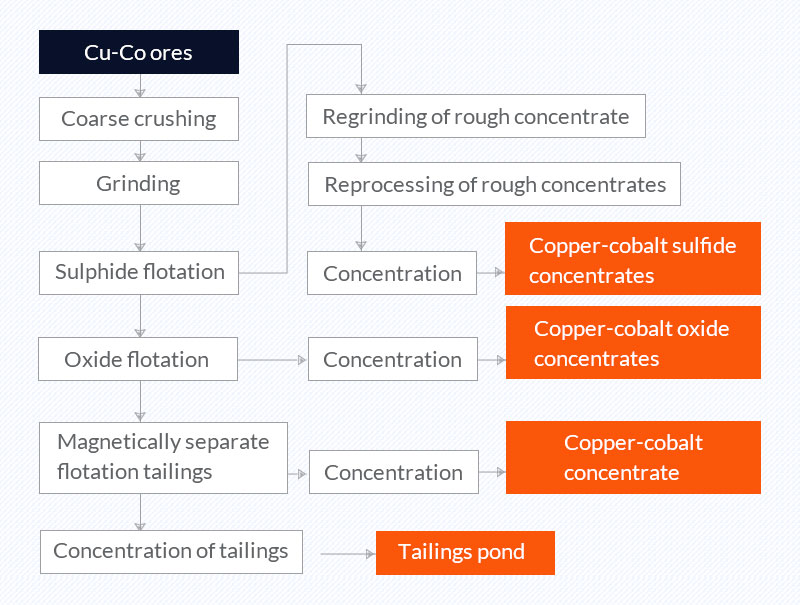

3. cobalt processing flowchart: sulfur before oxygen-floating regrinding and cleaning of copper sulfide coarse concentrate-tail magnetic separation

- Flotation equipment: Flotation machine

- Magnetic separation equipment: Magnetic separator

- Concentration equipment: High Efficiency Concentrator

- Flotation reagent: sodium hexametaphosphate, sodium hydrosulfide, butyl xanthate, pentaxanthate and foaming agent.

The obtained copper-cobalt sulfide concentrate and copper-cobalt oxide concentrate are further refined by corresponding methods.

Conclusion

The Katanga copper-cobalt ore belt of the Congo has huge reserves of copper and cobalt resources. Continuous optimization of cobalt mining and processing methods can improve resource utilization, reduce investment and production costs, ensure global cobalt supply, which is a scarce and vital strategic mineral resource.

The typical cobalt mining and processing methods described above have been successfully put into operation and achieved good production indicators, which can provide certain conditions for the green and efficient development of other similar copper-cobalt ore resources in Congo of reference.