Why crush slag? What can it do?

Slag is solid waste generated in producing metal, ore and building materials. It includes blast furnace, steel, copper and nickel slag, which are widely used in steel, non-ferrous metals and other industries.

What do people use slag for?

Some iron- and copper-containing smelting slags still contain metal components. These valuable metals can be recovered after crushing. It can also be reused in blast furnace, thereby achieving resource recycling and reducing environmental pollution.

Crushed slag aggregates or powders, meeting specified particle size requirements, can be used for base materials, embankments, fillers, and as aggregate in main road shoulders and hot asphalt mixtures. It can also be used as cement and concrete.

Rich in mineral elements such as calcium, magnesium and silicon, crushed slag can be widely used in agriculture for the production of new fertilizers. It can also improve soil structure, and be used for soil improvement. Some crushed metallurgical slag can be used to improve the ecological environment of farmland after harmless treatment.

Crushed slag can be recycled and reused. Choosing the right slag crusher means higher efficiency and better returns.

Need help with slag crushing? We offer reliable solutions for your plant.

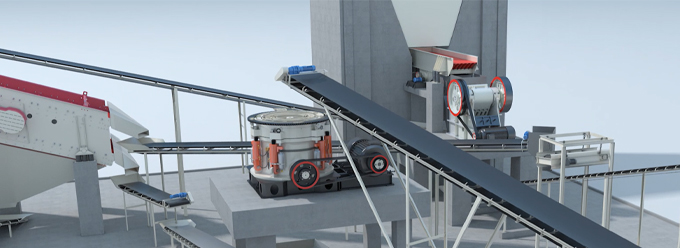

Three slag crushing machines to meet different needs

Slag crushers are widely used in steel, smelting, cement, building materials and recycling plants.

FTM Machinery, as a leading slag crusher manufacturer, dedicated to the production. We offer multiple customized models for different hardness, particle sizes and capacity, helping you build an efficient, profitable slag recycling production line.

1. Slag jaw crusher

Jaw crusher is the preferred solution for crushing hard slag.

Industrial slag such as steel slag, copper slag, or nickel slag possesses high hardness and abrasiveness, causing rapid wear on common crushers.

With high-manganese steel or alloy materials, jaw crusher's movable and fixed jaws in FTM Machinery show robust primary crushing performance and extend longer life when crushing the hardest slag.

Main benefits:

- The deep V-shaped crushing chamber provides a high crushing ratio without slag blockage.

- The large feed size allows crushing large slag below 1,200 mm generated from smelting.

- The hourly crushed slag aggregate output is 25% higher than similar crushers with a production capacity of 1,200 t/h.

- Wearing parts are easily replaceable and maintenance costs are low.

2. Slag cone crusher

After primary crushing, some slags are still large and hard that require crushing.

Cone crusher can further refine slag, especially for tough, abrasive slags like steel or copper slag.

The slag crusher offers finer particle size (3–64 mm) and outputs with a capacity of 36–1,500 t/h, meeting different scale slag recycling needs.

Main benefits:

- Its compression-style crushing results in slender, needle-shaped or flake-like slag particle.

- Equipped with an automated control system, production efficiency is increased by 15–25%.

- The main shaft, liner, and other components used in slag crushing are more robust and have lower wear rate.

- A compact structure and a small area. Low long-term investment costs for slag crushing.

3. Slag impact crusher

The impact crusher combines fine crushing and shaping of slag, making it suitable for secondary and tertiary crushing slag.

It can handle slag with a maximum feed size of 800 mm. Crushed slag aggregate is cube-shaped with smaller edges, showing better quality.

The slag crusher can handle low-to-medium hardness slag, such as aluminum slag. The capacity can be 30 t/h, 70 t/h, 400 t/h and the maximum is 2,000 t/h.

Main benefits:

- Each blow bar designed by FTM Machinery weighs 230 kg, heavier than ordinary blow bar, effectively resisting the impact and abrasion of slag.

- It can crush slag with high moisture content, achieving superior performance.

- It achieves excellent one-step crushing and shaping, ensuring crushed slag meet particle size needs, making it suitable for aggregate.

Cases of slag crushing plant

1. Indonesia: Crush slag for concrete production

A plant in Indonesia intended to recycle slag aggregate for concrete. Engineers in FTM Machinery made a suitable solution for their raw materials: a jaw crusher and an impact crusher.

- Model: PE jaw crusher, PF impact crusher

- Hardness: Medium-hard

- Capacity: 50 t/h

- Feeding size: ≤300 mm

- Discharging size: 2–5 mm, 5–10 mm, 10–20 mm

Customer feedback:

"The crushing line runs stably and continuously, producing high-quality crushed slag aggregate with excellent shapes. It has boosted production by 70% and cut labor costs by 40%, showing notable economic benefits."

2. Malaysia: Crush steel slag for road material

A steel mill in Malaysia has a large amount of industrial steel slag. They purchased jaw crusher and cone crusher from FTM Machinery, to crush and process the steel slag into road construction materials.

- Model: HD European jaw crusher, SC single-cylinder cone crusher

- Hardness: High

- Capacity: 20 t/h

- Feeding size: ≤1,000 mm

- Discharging size: 10–20 mm, 20–30 mm

Customer feedback:

"Since adopting FTM Machinery's steel slag crusher, the efficiency has doubled while energy has decreased. We have reused the steel slag and reduced waste and dust emissions, resulting in positive economic returns."

Conclusion

FTM Machinery can provide the comprehensive slag crushing solution aimed to meet various requirements.

Regardless of slag type—whether blast furnace slag, steel slag, copper slag, nickel slag, or aluminum slag—we can help you build an efficient slag crushing line tailored to your needs.

Want to learn more about slag crushers? Contact us for professional advice! Contact us