Exploring the world of wolframite

Wolframite, an iron-manganese tungsten oxide mineral, is commonly found associated with tin ores in granite and quartz mines.

Wolframite is one of the primary ores for extracting tungsten, drawing attention for its rich tungsten content.

Unique properties of wolframite

- Category: Oxide minerals

- Formula: (Fe,Mn)WO4

- Crystal system: Monoclinic

- Color: Grayish to brownish black

- Mohs scale hardness: 4–4.5

- Luster: Submetallic to resinous

- Streak: Reddish brown

- Diaphaneity: Opaque

- Specific gravity: 7–7.5

- Magnetism: Weak magnetism

- High melting point: 3,410℃ (6,170℉)

Extremely uneven distribution of tungsten resources

Tungsten resources are primarily concentrated in a handful of countries worldwide, notably China, Vietnam, and Russia. Among these nations, China holds the largest reserves and production of tungsten.

Here are the main country-wise figures for global tungsten mine production and reserves in 2023:

| Country | Mine production | Reserves |

|---|---|---|

| Australia | 800 | 570,000 |

| Austria | 910 | 10,000 |

| Bolivia | 1,500 | NA |

| China | 63,000 | 2,300,000 |

| Korea, North | 1,700 | 29,000 |

| Portugal | 500 | 4,000 |

| Russia | 2,000 | 400,000 |

| Rwanda | 1,400 | NA |

| Spain | 1,500 | 66,000 |

| Vietnam | 3,500 | 74,000 |

| Other countries | 1,100 | 950,000 |

Data from the United States Geological Survey (USGS)

From the data in the table, it is evident that China holds a significant lead in both tungsten mine production and reserves, asserting its dominant position in the global tungsten market.

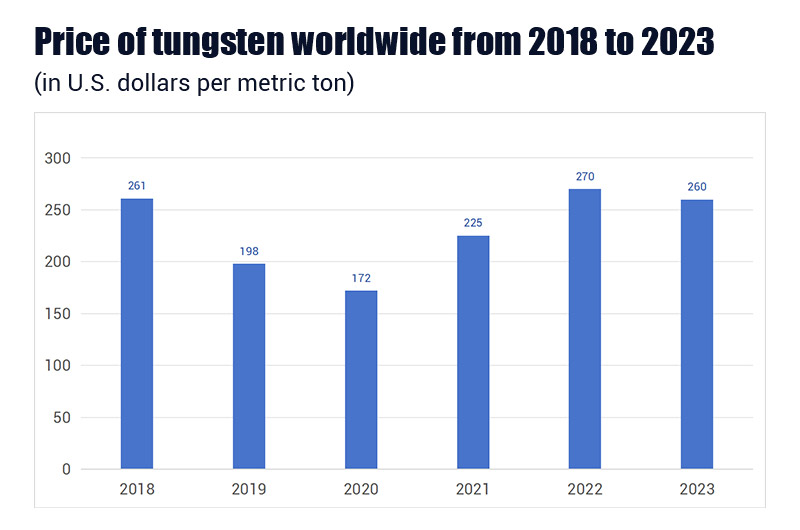

Tungsten Price

According to Statista, the average price of tungsten in 2022 rose by 20% to about $270 per metric ton of tungsten trioxide but saw a slight decline in 2023 to around $260 per metric ton.

The global COVID-19 pandemic severely impacted tungsten demand and production.

However, with major industries gradually resuming operations, demand for tungsten products in sectors like metallurgy, electronics, and automotive manufacturing has been steadily increasing, leading to a rise in tungsten prices and eventual stabilization.

Exploring the mysteries of wolframite processing

Only scheelite and wolframite among over twenty tungsten minerals found in nature have industrial mining value. Even more surprising is that the useful tungsten content in most tungsten minerals is below 1.5%.

Wolframite ores are complex and commonly undergo a combined process of gravity separation, flotation, and magnetic separation. However, recovering tungsten concentrate through gravity separation is challenging, particularly with fine-grained ores.

We once assisted a wolframite ore processing plant in Son La province, Vietnam in configuring processing equipment.

The wolframite ore here contains small amounts of cassiterite, pyrite, magnetite, quartz, feldspar, and others. Tungsten mineral phase analysis shows a WO3 content of 1.55% in the ore.

After multiple exploratory experiments, we have determined a process for the plant involving crushing, grinding, flotation, and three magnetic separation to recover tungsten concentrate along with valuable minerals like sulfur and iron concentrates.

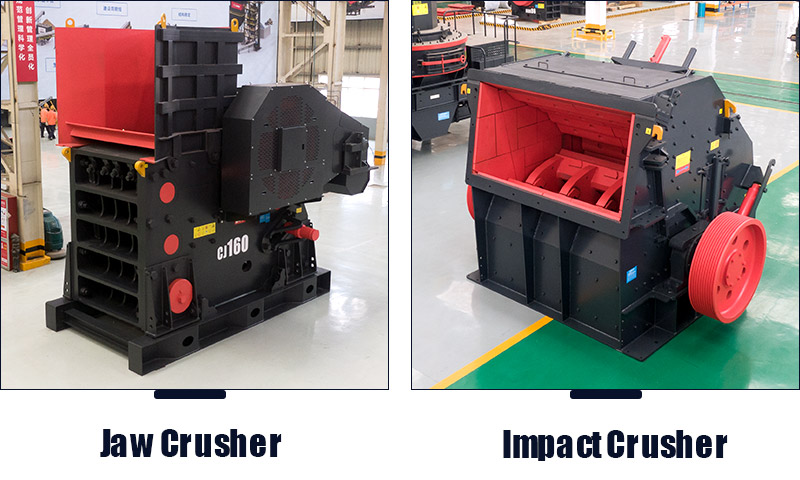

1. Wolframite Ore Crushing

The tungsten ore is successfully crushed to below 15 mm through coarse crushing with a jaw crusher and fine crushing with an impact crusher after mining.

2. Wolframite Ore Grinding

Wolframite is brittle and easily crushed, leading to the production of tungsten slimes during the crushing and grinding process. A rod mill is a great choice in this case, as it ensures uniform particle size and prevents over-crushing.

As the fineness of grinding increases, the amount of tungsten slimes produced during the grinding process gradually increases, leading to potential losses in tailings and a decrease in tungsten recovery rates.

To maintain high tungsten recovery rates, we determined that a grinding fineness of -74 μm with a content of 46% is the most suitable option.

3. Strong Magnetic Roughing

Wolframite is a weakly magnetic mineral, and the magnetic field intensity is a crucial factor affecting the grade and recovery rate of wolframite during magnetic separation.

When the magnetic field intensity of the strong magnetic separator is set at 1.3 T, the magnetic separation recovery indicators are optimal, with the WO3 recovery rate reaching its maximum value in the concentrate.

4. Flotation Desulfurization

With the help of two flotation machines, after three stages of flotation—roughing, scavenging, and concentration under -74 µm fineness with an 80% content—and using 10 g/t of butyl xanthate as a collector, we obtained sulfur concentrate with an S content of 33.37% and a recovery rate of 36.41%.

5. Weak Magnetic Iron Separation

The weak magnetic separator is utilized for iron separation. Of course, before this, demagnetization treatment is required for the desulfurized tungsten concentrate.

Finally, we obtained iron concentrate with an Fe grade of 65.18% and an iron recovery rate of 78.03%.

6. Strong Magnetic Tungsten Separation Feel free to consult

The tungsten concentrate after iron removal mainly consists of wolframite and vein minerals. Therefore, we employed strong magnetic separator once again for wolframite concentration to enhance the recovery of tungsten slimes.

Through strong magnetic separation, we obtained a tungsten concentrate with a WO3 grade of 60.76% and a recovery rate of 91.42%.

In addition to obtaining tungsten from wolframite ore, valuable tungsten components can also be recovered from scrap tungsten through mechanical crushing, zinc smelting, electrolysis, and other methods.

The tungsten content in scrap tungsten is rich. Recycling scrap tungsten can reduce natural resource extraction, lower production costs for businesses, effectively reduce landfill waste, and save valuable raw resources.

What is tungsten used for?

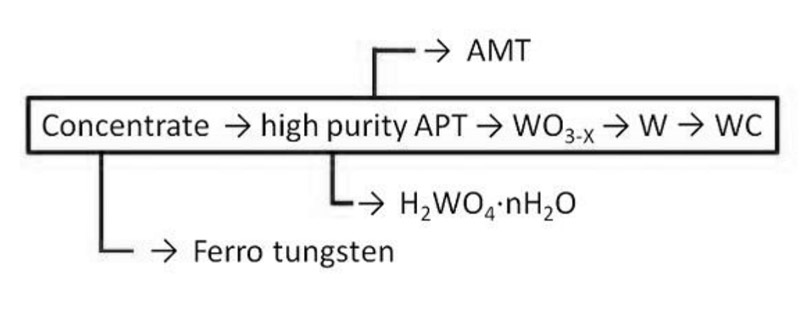

Most tungsten concentrates are purchased by secondary processing companies after production, primarily converting them into Ammonium Paratungstate (APT), which is the most common form for trading tungsten.

APT is then refined and converted into tungsten powder (W), which is used by third-party manufacturers to make downstream metals and alloys.

Tungsten extracted from scheelite has a high melting point, high density, high strength, as well as good electrical and thermal conductivity, making it an important strategic metal.

- Manufacture of hard alloys: Tungsten carbide is a key raw material in the manufacture of hard alloys. Hard alloys, known for their high hardness and wear resistance, are widely used in crafting cutting tools, drill bits, planer blades, grinding tools, and more.

- Manufacture of high-temperature alloys: Tungsten's high melting point makes it ideal for crafting components for aerospace engines, nuclear reactors, and other high-temperature applications.

- Electronics industry: Tungsten is also used in the manufacturing of filaments, electrodes, electronic devices, vacuum tubes, light-emitting diodes (LEDs), and more.

- Radiation shielding materials: Tungsten has good absorption capabilities for X-rays and gamma rays, making it useful as a radiation shielding material in medical and nuclear industries.

- Chemical catalysts: Tungsten compounds are also used as components in chemical catalysts for organic synthesis and other fields.