Just like other stone crusher machines, jaw crusher also needs a regular repair and maintenance after a certain time of working, or it will get decreased service life because of severe wear of important parts.

What will cause if you do not make a regular maintenance?

Jaw dies wears so much that must be changed

So many customers have common misconception that jaw plates only need repair when appearing flat, holes, cracks. Actually if jaw plates wears badly, it is not only hard to repair but seriously affects the normal working of other parts, which then will take a great sum of money to change a jaw plate and maintain other parts.

hole, flat, cracks on jaw crusher plate

Pitman bearing broken

Although the main crushing process is complemented by jaw plates, the crucial parts that give a motion to the moveable jaw plate are toggle plate, pitman bearing and flywheel.

The pitman drives the moveable jaw dies to push stone material towards stationary jaws, which would create strong pressing forces to both jaw dies. Therefore, if the pitman cannot get lubrication in time, it will be broken under the high pressure of material and interrupt the whole work.

How to correctly check and maintain a jaw crusher?

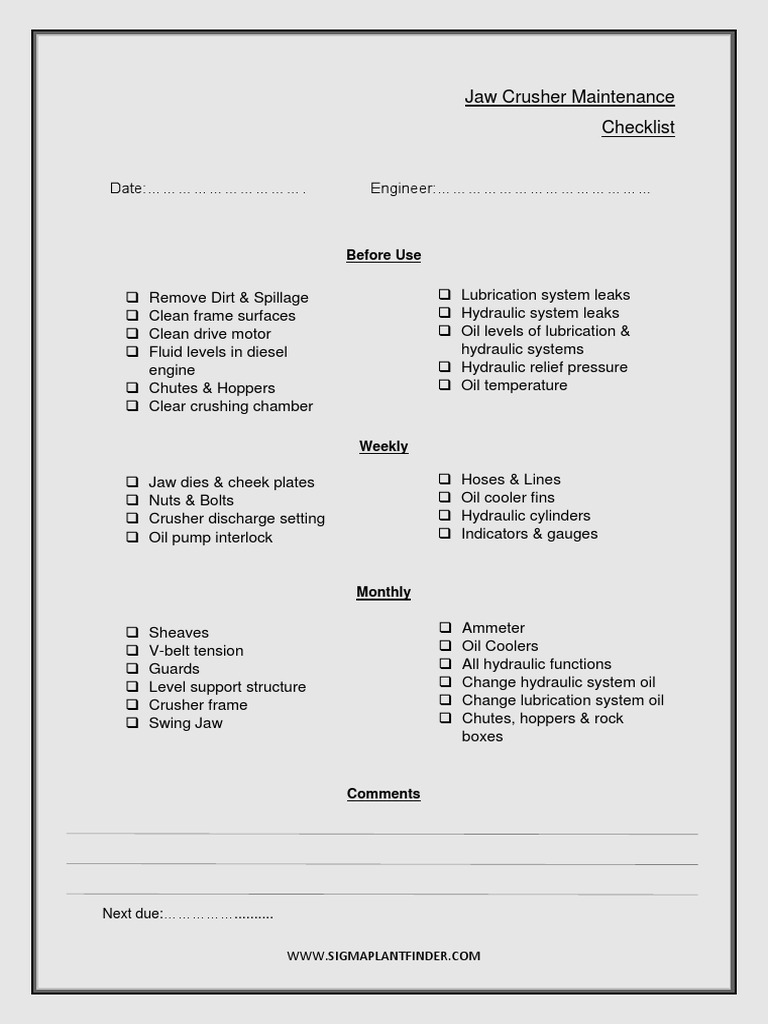

1.Make a checklist

Proper plan and preparation make the whole repair and maintenance ordered and effective, which helps operators save time, cost, and enhance their safety. You can make a checklist just like the following chart in which you can list need-checked jaw crusher parts with a different period then making a mark if you are done with them. This not only prevents missed inspections, but also makes the arrangement clear, and saves a lot of time.

a template of jaw crusher checklist

2.Do the lubrication job well

The lubrication of the interface between the parts of the jaw crusher is very important. It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life.

Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil. When using grease, there may be several different ways to inject it into the necessary lubrication points. It can be operated manually with a grease gun, an oiler or metering pump.

Video of automatic lubrication system of a jaw crusher

Which parts need to be lubricated?

Eccentric shaft (pitman bearing): It is behind the moveable jaw plate, and together with flywheel with toggle plate to create a motion. So, the most important thing you must do is keeping a regular lubrication to eccentric shaft, or you will spend more than four hours in changing a new one when it is broken.

Main shaft To keep the main shaft in good lubricating situation, you need to guarantee enough geese between thrust plate.The grease added to the bearing box needs to occupy about 50% of its space and be replaced every 3-6 months. When changing the engine oil, please use clean gasoline or kerosene to clean the roller bearing raceways.

3.How to maintain and replace jaw plates?

There are different jaw plates material in the market, and some of them suits for hard stone while other is not. Therefore, you have to choose the right jaw plate for your crusher. For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production.

It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance.

- 1Check whether the tooth peak to tooth valley is match with each other.

- 2Regularly check whether the bolts and nuts have been tightened so you must ensure that they will not loosen during work.

- 3Check whether the jaw surface appears flat, hole, crack, if it does, do some adjustment or change new ones.

- 4If more than 80% of the jaw plate is found to be worn during the inspection, you need to replace the jaw plate in time for not affecting the overall performance of the machine.

- 5If you don't know whether to replace it, contact the jaw crusher manufacturer, and they will give you the most professional advice according to the real situation of jaw plate.

How to replace jaw crusher plates?

Inspection and maintenance of other parts

- Check whether the discharge port is blocked, remove the blockage in time, and keep the discharge unobstructed.

- Check whether the V-belt is loose. If it is too loose, you need tight it because loose belt will cause slippage.

- Whether the eccentric shaft is blocked. The main reason is that if bush of the eccentric shaft is loose, there is no gap on both sides of the bearing box of the frame. At this time, the bush should be reinstalled or replaced.

- Check whether the position of the wedge of the flywheel is offset and correct it in time.

Common problems during inspection and repair of jaw crusher

How to tell when pitman bearings are bad on a jaw crusher?

- 1The internal contamination of the bearing is too high, which is mainly reflected in the increase in oil and grease. Such as, iron content is higher than 150ppm, copper over 200ppm, silicon dioxide over 150mmp, and moisture content is greater than 0.5mmp.

- 2The bearing temperature is abnormal. Look at the swing jaw bearing box and the mainframe bearing box separately to see whether the temperature difference between both is too large. If temperature difference over 15 – 20 OF, it is sure that the bearing got some problem.

- 3There is noise inside the bearing. Noise also indicates that issues on connecting rod bearing.

How to adjust the toggle plate of the jaw crusher?

The function of toggle plate is to adjust the outlet of the jaw crusher to the desired size. There are two specific methods: one is to replace the support pad between the toggle plate and the body frame, and the other is to adjust the two wedges between the toggle and the body frame.

Fote Company has more than 40-year manufacturing experience, mainly engineering different types of jaw crushers including PE jaw crusher, Dodge jaw crusher, Blake type jaw crusher(double toggle jaw crushers), single toggle jaw cruhser, etc., and all of them can be customized.