What is an iron Powder Briquetting Machine?

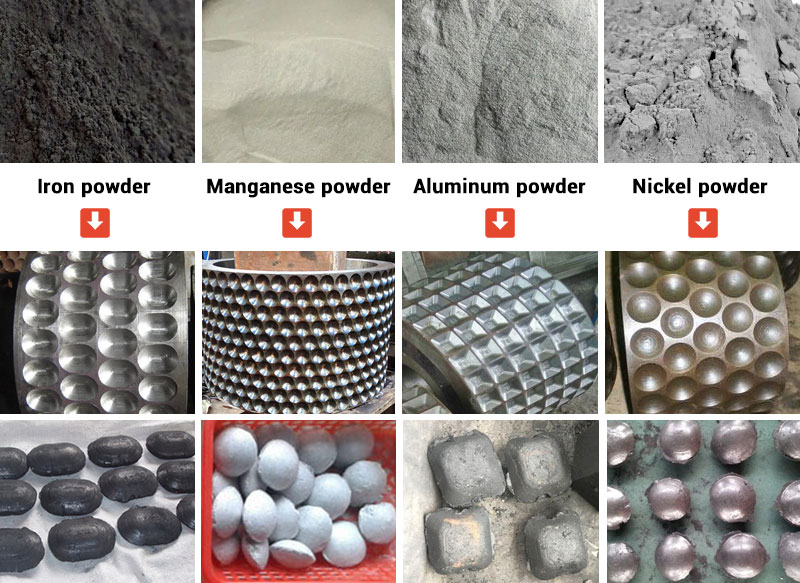

FTM Machinery iron powder briquetting machine, also known as metal powder briquette press machine, is a kind of briquetting machine for processing metal ore powders and recovering slag. With the help of high-pressure rollers, it can easily press the dry powder into balls of various shapes and sizes.

The finished briquettes (such as aluminum briquettes) can be designed into the shapes of oval, round, square, and pillow. Each briquette has a complete shape and high strength and is highly praised in the metallurgical and chemical industries.

The structure of iron powder briquetting machine

The iron powder briquetting machine has a simple structure and short technological process. It is mainly composed of a feeding part, a transmission part, and a forming part. The whole machine is rigid and has the following unique parts design:

- The pressure roller is forged from wear-resistant alloy.

- The bearing adopts rolling mill bearing series, which has been quenched and tempered.

- The steel plate is sprayed with four painting layers of paint for waterproof, acid-proof, powder-proof, and sun-proof. This feature makes the machine durable in use.

How does an iron powder briquetting machine work?

The iron powder briquetting press is suitable for pressing high-strength materials. It consists of two counter-rotating rollers held under pressure, which use force to compress the material into the shape you specify. Roll pocket designs are customizable to meet your size and shape specifications.

A feed screw mounted above the rollers pre-compacts the fine feed material while providing de-aeration if necessary and delivering a consistent feed stream to the briquette press.

Roll timing is adjusted at the factory to precisely align the roll pockets to produce a consistent briquette, pellet, or customized shape.

Why FTM Machinery iron powder briquetting machines?

- Maximum recovery of metal powder and slag, reducing waste of resources

- Fully automatic PLC control system, realize easy and efficient briquetting work

- Briquettes are extremely tough and unbreakable

- Easy to replace grinding tools and adjust the shape of briquettes

- Energy saving and environmental protection, no risk of dust spillage

- Emergency safety system

Customer cases

1.Iron powder briquetting plant in America

The resources of metal ores in America are abundant. To improve the comprehensive utilization rate of metal powders and slag, users will choose the iron briquetting presses to improve their use-value.

In January 2022, a hematite processing plant in America asked us to provide a complete iron powder briquette production line. After mineral testing, FTM Machinery engineers designed a briquetting process, including crushing, grinding, beneficiation, adding binders, mixing, briquetting, and drying.

- Equipment capacity: 18 t/h

- Delivery date: October 4, 2022

- Address: America

- Project features: Low equipment investment with high profit and excellent finished products.

- Production and installation: It took about 30 days from signing the contract to designing the entire production line, producing a complete set of production equipment, on-site installation, and finally putting it into production.

So far, the iron powder briquetting production line is running well, bringing huge economic and social benefits to our customers. He is very satisfied with our product.

2.Chrome ore fines briquetting plant in South Africa

A chromite ore fines processing plant in South Africa asked FTM Machinery to provide a high-efficiency chromite briquetting machine. This can achieve optimal and efficient utilization of furnace capacity, as well as facilitate transportation and storage.

- The particle size of raw chrome ore powder is controlled between 0–5 mm.

- Remove excess impurities, especially large metals, such as nails, iron stones, stones, etc., which are likely to damage the roller.

- Mix dry chrome powder, suitable binders (such as molasses) and lime powder.

- Send the mixture into the chrome ore briquetting machine.

Finally, the entire chrome ore powder briquette production line feeds smoothly and evenly. The workload of the briquetting machine is stable and the production efficiency is high, which solves the problem of the low utilization rate of chrome ore powder.

Frequently asked question about iron powder briquetting machines

Does the iron powder briquetting machine have to use a binder?

- Yes, it does. To obtain briquettes of the desired quality, we must use a binder. These binders hold the coal particles together. The types of binders include Portland cement, asphalt, asphalt, water glass, clay, plastic, sulfur liquid, lime, bentonite, tar, molasses, etc.

Parameter

| Model | Roller Diameter (mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |