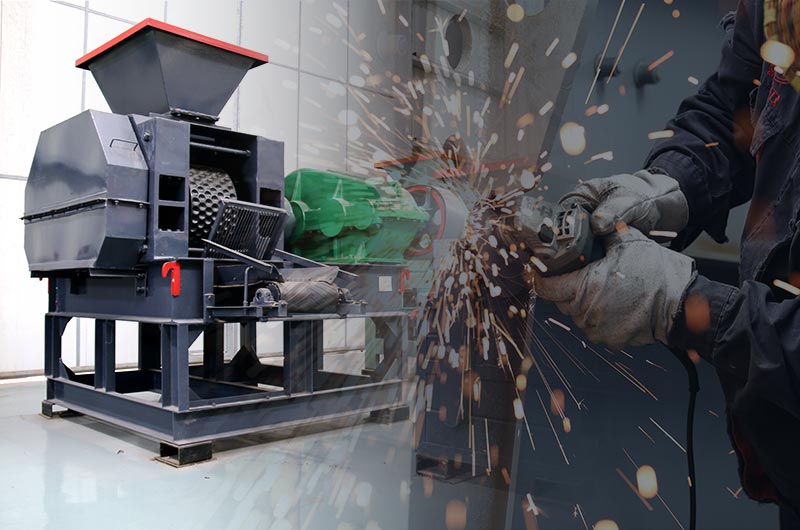

The charcoal briquette machine, also known as the charcoal extruder, is important forming equipment that can press difficult-to-form coal or charcoal powder into briquettes of different shapes.

Charcoal briquettes are small in size, which is convenient for storage, transportation, and use. They burn cleanly and create huge economic benefits, so industries such as renewable energy, barbecue (BBQ), furniture, metallurgy, transportation, and heating are willing to invest in the briquette plant.

How to make charcoal briquettes with a charcoal briquette machine?

Make charcoal briquettes in 3 easy steps. Learn about Charcoal Briquettes: Ingredients and Process.

- 1Prepare coal or charcoal powder that meets the requirements.

- 2Add accelerator (such as 10–20% wood chips), lime, and binder (such as 3–5% cornstarch), and then mix with powder evenly.

- 3The mixture is fed into a charcoal briquette machine. After continuous extrusion, briquettes of different shapes are obtained.

Although the briquette making process is simple, the briquette machine has strict requirements for materials:

- Biomass materials cannot go directly into the briquette machine. They must be carbonized before being ground into powder.

- The particle size of powdery material is controlled within 8 mm. The smaller the particle size, the easier it is to briquette.

- The powder humidity can be dried to 5–10% because it is not easy to form a ball if it is too wet or too dry.

- Do not mix iron nuggets or high-hardness massive debris in the powder, so as not to damage the rollers and shafts.

Charcoal briquette machines for sale

FTM Machiney specializes in the development and manufacturing of briquette making machines. For more than 40 years, we have continuously improved the structure and parameters of the machines to produce more market-friendly charcoal briquettes.

The structure of charcoal briquette machines

The charcoal briquette machine is a spiral extrusion molding machine, which consists of three parts: feeding, transmission, and molding.

1. Feeding part: The spiral feeding device is driven by an electromagnetic speed-regulating motor. With the help of a belt pulley and double-shaft reducer, the material is sent into the feeding hopper to realize quantitative feeding.

2. Transmission part: The machine is driven by an electric motor. The worm delivers the mixture to the rollers, and the continuous water spray prevents the mixture from sticking to the rollers. Then, the rollers do the periodic rotating and ball-forming movement to complete mass production.

3. Forming part: The mold made of 65Mn material determines the briquette shapes, such as square, round, oval, pillow, or other special shapes. As the main wearing part, the mold is assembled in combination and can be replaced after wear. After special heat treatment, its hardness can reach above 58 degrees.

The charcoal briquettes are hard and plump, with high carbon content (above 90%) and low moisture (below 5%), so they burn well.

Models and specifications of charcoal briquette machines

The smaller the ball press, the smaller the size of the product. The minimum forming size is 20–25 mm.

| Power | 5.5–90 kW |

| Roller Diameter | 290–1,000 mm |

| Capacity | 1–35 t/h |

| Output size | 20–75 mm |

For specific specifications, see the end of the article.

Why FTM Machinery charcoal briquette machines?

FTM Machinery is a high-tech enterprise integrating R&D, production, sales, and service with a large briquette production base. Our charcoal briquette machines have the following unique advantages:

- A wide range of raw materials: The machine can make full use of coal powder and various biomass wastes to produce briquettes in an energy-efficient way, thereby bringing huge economic benefits.

- Stable operation: Advanced PLC program control, stable hydraulic system and mature vibration forming technology ensure that the machine is fully automatic and runs stably.

- Convenient feeding: The unique forced feeding device of charcoal briquette machinery can ensure that each product in the mold box is full, even, and dense.

- Rapid forming: Advanced forming mold combined vibration can fully exhaust the material within 3–5 seconds to ensure the high density and high strength of the product.

- High-quality products: The briquettes burn long, have no smoke and odor, and can withstand 10 drops without breaking.

- Various shapes: The machine can produce different shapes and specifications of charcoal briquettes by changing the special-shaped mold.

- Personalized customization: The roller diameter and machine power can be designed according to customer requirements.

- High-strength wear-resistant material: The mold surface is made of special synthetic manganese steel material. The double-shaft reducer structure can improve roller precision. The gear adopts a hard-toothed type to improve the reducer's performance and life.

- Easy installation and maintenance: Easy replacement of propellers, molds, and bearings.

Customer cases

FTM Machinery has rich experience in making charcoal briquettes and has helped Kenya, South Africa, the Philippines, Indonesia, Zambia, Nigeria, India, Paraguay, Brazil, Malaysia, Thailand, Russia, Uganda, Ghana, Sri Lanka, and other countries produce popular charcoal briquettes products.

1. Sawdust briquette charcoal making in India

Sawdust, the fine wood particle chips during sawing process, accounts for about 12% of new residue generated at sawmills. It is the primary raw material suitable for producing briquette charcoals.

The correct sawdust density is necessary to produce high-quality briquette charcoals, generally consisting of 70% medium density and 30% heavy density hardwood.

The sawdust charcoal briquettes process is as follows:

- 1The sawdust is conveyed to a vibrating screen to remove impurities like metal, bark, pebbles, and plastics.

- 2The clean and uniform-sized sawdust is conveyed through a continuous dryer to achieve the final moisture content of 3.7%–4.5%.

- 3The dried sawdust is sent to a carbonization furnace to get burned sawdust powder.

- 4The sawdust powder is pressed by a charcoal briquette machine to make uniform round briquettes.

2. Press bamboo waste into charcoal briquettes in South Africa

The briquette making technology can utilize the wastes from bamboo processing. Not only does this help reduce pressure on wood resources, but it also helps farmers generate more income.

It is simple to press bamboo into charcoal briquettes. First, thoroughly mix the binder and charcoal. Then, immediately shape them into briquettes.

The primary bamboo charcoal briquettes contain moisture, so you must dry them under the sun for 1–2 days.

3. Coconut shell charcoal briquette making in the Philippines

The Philippines is known for its major agricultural and forestry sectors and has a large amount of biomass.

The Philippines is also a country that supplies agricultural residues to other countries that have increased the benefits of developing the country's economy.

In May 2018, a Filipino customer found FTM Machinery through the 24/7 hotline to offer him a set of coconut shell charcoal briquette machines.

Project Overview:

- Equipment capacity: 28 t/h

- Delivery date: July 15, 2018

- Address: The Philippines

- Project features: Less equipment investment, quick return results, and comprehensive benefits

- Application requirements: It turns coconut shell waste into a renewable eco-friendly coconut charcoal briquette. The briquette is an excellent alternative to charcoal fossil fuels with low ash content, high calorific value, and high combustion efficiency. So, it is often used for heating purposes in industry. In the Philippines, 92% of the industry's fuel is replaced by the highest quality charcoal briquettes, which are cheaper than coal.

- Production and installation: It took 30 days from the signing of the contract, production line design, production of a complete set of equipment, on-site installation, to final production.

In the past 5 years, the charcoal briquette machine production line performed well and brought huge benefits to our customers.

More cases of charcoal briquettes:Frequently asked questions about charcoal Briquette machines

Question 1: What equipment is necessary to start a biomass briquettes factory?

- Biomass Charcoal Briquettes refer to the charcoal of carbonized biomass briquettes. This means that you need to carbonize the biomass material first. There are two options: add a carbonization furnace or build a charcoal kiln to start a charcoal business.

- Biomass molding machines include crushers, dryers, and charcoal briquette machines. The hammer crushers can grind the material into powder. The rotary drum dryers can control powder moisture. Finally, the charcoal extruder can press the material into the shape and specification you want.

Question 2: Briquette Vs. Charcoal. Does the briquette burn longer than charcoal? Is it cheaper?

- Lump charcoal and charcoal briquettes are both used in various applications.

- Briquette is merely a lump of charcoal that has been ground up mixed with some binders and pressed into its briquette uniform shape. However, lump charcoal has different thicknesses, and it cannot burn evenly, which leads to pop, crackle, and a lot of smoke.

- The advantages of briquette are as follows:

- a. It is uniform so that you get a much more controlled burnout of these charcoal briquettes. For example, it is consistent with how long it burns and what temperature it burns at.

- b. Briquette can burn for at least 3 hours, which is actually 6 times more efficient compared to conventional firewood.

- c. Another reason why people like charcoal briquette is that it provides only heat without other odor tastes. Therefore, charcoal briquette is the best choice to barbecue.

- d. Besides, the briquette is a lot cheaper than charcoal.

Learn more about The Faults and Solutions of the Charcoal Briquette Machine.

Parameter

| Model | Roller Diameter (mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |