Charcoal briquette is a kind of fuel made from charcoal powder. Compared with traditional fuels, charcoal briquettes can not only generate heat continuously but also produce no smoke and odor during combustion.

Therefore, it has been widely used in domestic and industrial applications in recent years and has become the most popular fuel in many countries such as Kenya, the Middle East, Uganda, India, etc.

With the increase in its economic benefits, the charcoal briquettes process has become one of the hottest processing industries. So, what are the ingredients of charcoal briquettes and how to make charcoal briquettes?

How to make charcoal briquettes?

Composition of charcoal briquettes

The charcoal briquette is mainly composed of two parts, the charcoal which is used to provide heat and the minor ingredients. Charcoal is the product of incomplete combustion of wood or wood raw materials or pyrolysis under the condition of air isolation.

Its main component is carbon, so it can be used as fuel. The minor ingredients include accelerants, white ash, and briquette binder.

Component 1: Charcoal

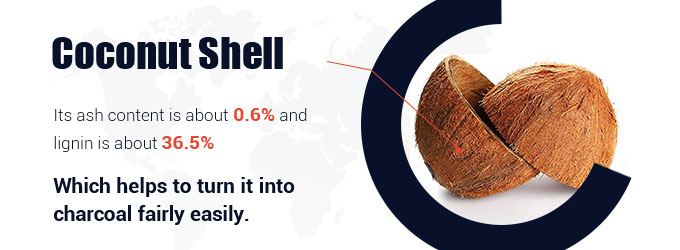

Charcoal accounts for more than 70% of the entire charcoal briquettes. As the combustion material providing heat, the raw materials for charcoal can be various woods, such as beech, birch, hard maple, pecan, and oak.

The charcoal is mainly processed by the kiln. In general, the charcoal produced and extinguished in the kiln is called black wood charcoal. It has the advantage of being easy to ignite, but it is easy to explode during burning with a short burning time and much smoke.

Black wood charcoal and white wood charcoal

While the white wood charcoal can be oxidized and generate white ash after being carbonized, removed from the kiln and quenched with wet sand. Compared with black wood charcoal, it has a harder texture.

Component 2: Accelerants

The charcoal briquette cannot fully into contact with oxygen during the combustion process, so the accelerator is needed to accelerate the combustion. The most suitable accelerator is the nitrate, which can not only provide oxygen to accelerate combustion but also heat during combustion.

However, it is too expensive. As an excellent accelerator with lower cost, 10% -20% of sawdust can be added to effectively increase the burning speed.

Sawdust is a good accelerant for charcoal briquettes

Component 3: White ash

As one of the minor ingredients, white ash accounts for only 2% -3% of the charcoal briquette. But it plays a very important role in the burning process of charcoal briquettes.

By observing the degree of turning white, we can judge the burning degree of the charcoal briquette. In addition, because the white ash is not combustible, it can effectively extend the burning time.

White ash—the sign to judge the degree of burning

Component 4: Briquette binder

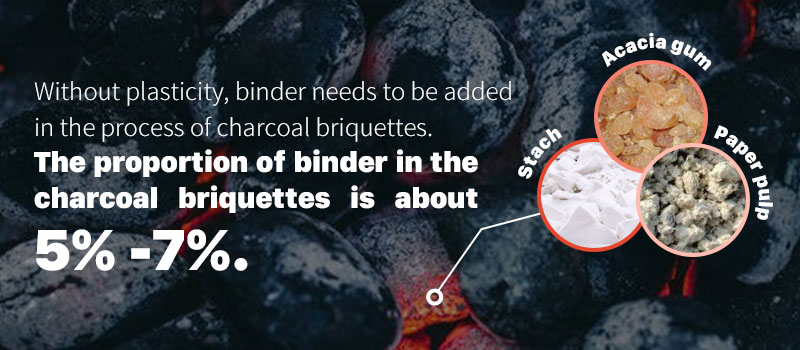

Due to the lack of plasticity, the binder needs to be added in the process of charcoal briquettes. The proportion of binder in the charcoal briquettes is about 5% - 7%.

3 types of binders for charcoal briquettes

Numerous facts show that starch has the best performance as a binding material. After it's gelatinized, a thick paste can be formed so that the charcoal powder is stuck together to facilitate the later briquette.

Another popular briquette binder is Arabic gum or acacia gum. However, considering the cost, the best choice is the waste paper pulp.

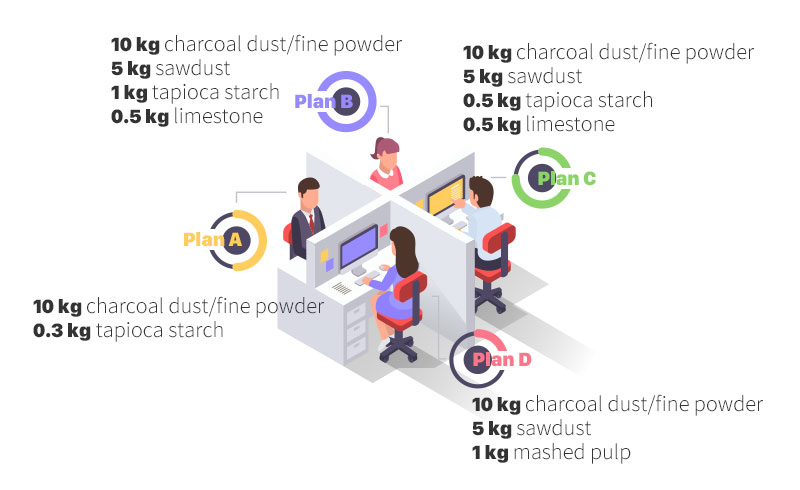

With different composition ratios, the final material produced will be different. The following are several appropriate recipes for making charcoal briquettes:

Low-cost plans for material matching

Here is an interesting video that shows a man making his briquettes at home using scrap pieces of wood and bark. Watch the video to have some fun and you can even have a try if you are interested.

Advantages of charcoal briquettes

- High combustion value (more than 80% of biomass mass)

- Longer burning time as well as a more uniform and stable burning process

- Smokeless and tasteless

- Lighter (only 1/5 to 1/3 of the original weight)

- Cheaper than lumpy charcoal

- Easy to handle, pack, transport, and use

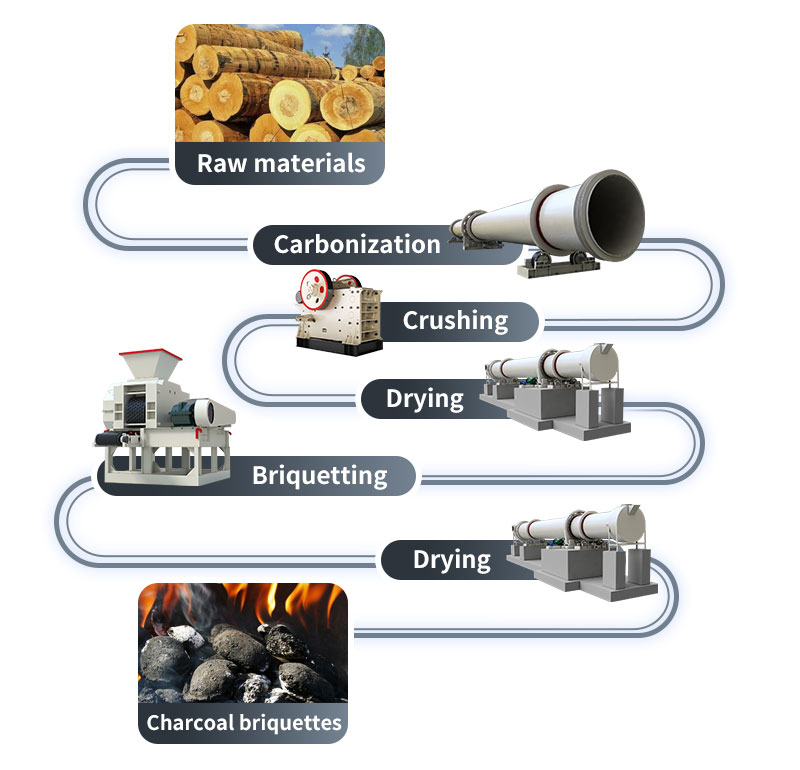

Process of making charcoal briquettes

How to produce charcoal briquettes is a question that people generally care about. The process of making charcoal briquettes can be divided into five steps:

Step 1: Carbonization

Firstly, fire the raw materials in a rotary kiln. During the one-week combustion process, the temperature needs to be maintained at approximately 840-950 °F (450-510 °C).

After the end of combustion, close the air inlet, and after one to two hours of exhaust, close the exhaust hole. After a two-week cooling period, empty the kiln and crush the carbonized wood (charcoal).

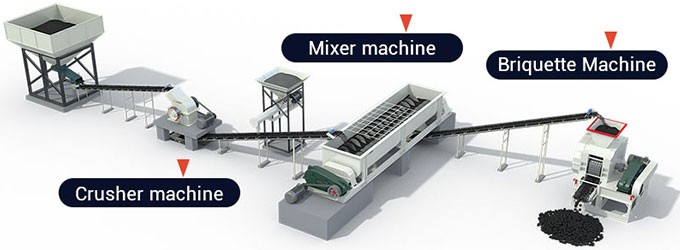

Step 2: Crushing

Use a hammer crusher or roller crusher to crush the carbonized wood. Although different types of wood such as bark, dry wood chips, and wet wood should be crushed to different sizes, generally they can be crushed into pieces of charcoal to 5mm below to make high-quality charcoal briquettes.

Step 3: Drying

Then a drying process is needed. If the water content exceeds the empirical upper limit, the temperature will rise and the volume will expand suddenly, which is easy to cause an explosion. If the moisture content is too low, it will be difficult to mold. Use a dryer to reduce its moisture content to the level required for briquette formation by about half (to about 15%).

Step 4: Briquetting

Briquetting is a key step in charcoal molding. After the raw materials enter the ball press, they will be subjected to three kinds of forces, namely the main driving force of the briquette machine, the friction force, and the centripetal force of the wall.

Due to moisture, adhesives, temperature (about 105 °F or 40 °C), and pressure of the rollers of the briquetting machine, the charcoal briquettes can maintain their shape when they fall from the bottom of the machine.

A briquetting machine can produce satisfied charcoal briquettes

Step 5: Drying

Feed the charcoal briquettes into the dryer for about three to four hours to heat them to 275 °F (135 °C) and reduce the moisture to about 5%.

After production, bag the charcoal briquettes immediately or stored them in silos. Following the above steps, charcoal briquettes will be produced at a production rate of 2200-20,000 pounds (1-9 metric tons) per hour.

5 steps for making charcoal briquettes

Successful cases of Ftmmachinery charcoal briquette making lines

Kenya 20 t/h charcoal briquette production line

20 t/h charcoal briquette production line in Kenya Get the Latest Price

| Production capacity | 20 t/h |

| Processing material | Charcoal |

| Equipment configuration |

Double-shaft mixer, liquid mixer, feeder, charcoal briquette making machine, dryer, conveyor, etc. |

| Charcoal briquette size | 50 mm (in diameter) |

| Charcoal briquette shape | Pillow |

Customer feedback:

The charcoal briquette formed by the briquette machine is more resistant to high pressure, not easy to break, and easy to transport.

.

.

Uganda 5-6 t/h charcoal briquette making line

5-6 t/h charcoal briquette making line in Uganda Get the Latest Price

| Production capacity | 5-6 t/h |

| Processing material | Charcoal |

| Equipment configuration | Screw feeder, liquid mixing tank, mixer, charcoal briquetting machine, sawdust dryer, conveyor, etc. |

| Charcoal briquette size | 30 mm (in diameter) |

| Charcoal briquette shape | Round |

Customer feedback:

The charcoal briquette formed by the briquette machine burns longer with more heat and less smoke and pollution.

Advantages of charcoal briquettes during processing

Compared with other fuels, the biggest advantage of charcoal briquette is that it has no environmental pollution during the whole process.

- No waste material: With no chemicals added during the entire processing of charcoal briquette, the required minor ingredients can be replaced with sawdust, waste paper pulp, etc. Not only there is no waste slag, but some waste can also be recycled and reused to create benefits.

- No waste liquid: The whole process does not need to be added or drained water or any liquid, so it will cause no pollution to the water source.

- No waste gas: The gas generated during the processing of charcoal briquette is only water vapor and some combustible gas which causes no air pollution. It is worth mentioning that this part of combustible gas can be recycled and used as fuel, which can reduce the cost at the same time.

Conclusion

According to the content above, it is not so difficult to process charcoal briquettes. But we need to pay attention to many details, such as component ratio, and moisture, all of which will directly affect the final quality.

Therefore, the author recommends that the users need to understand and confirm every step and detail of the charcoal briquette processing ahead. And then choose a reliable supplier for the purchase of the equipment needed in the processing, such as a rock crusher, dryer, briquette machine, etc.