India, as a great agricultural country, 80% of its population depends on agriculture for a living, so a large number of agricultural residues are generated.

However, these fuels are not fully utilized, not only cannot meet people's needs, but also cause serious environmental pollution.

Therefore, it is imminent to replace fossil fuels with charcoal briquettes. Charcoal briquettes are made by charcoal powder with a briquette making machine, which can be widely used in households, commerce, industry, agriculture and other fields.

Status of energy use in India

Heavy dependence on imported oil

Over the past 25 years, India has imported more than 119.2 million tons of crude oil and petroleum annually, even as the use of conventional energy sources such as petroleum, coal and electricity has greatly increased among the ASEAN economies.

The heavy dependence on imported oil has led to economic and social uncertainty.

Heavy dependence on imported oil in India

Currently, India has a strong interest in developing renewable energy technologies for both environmental (pollutant release and depletion of fossil reserves) and economic reasons.

Wide use range of biofuels

Due to the high cost of non-biofuels such as coal and natural gas, households in rural India are highly dependent on available biofuel sources such as firewood, manure cakes and agricultural residues as their primary energy source.

Wide use range of biofuels in India

It is estimated that about 96% of rural households are using biofuels. These fuels predominate in the home and are used mainly for cooking.

The following table shows the consumption of firewood, manure cakes and agricultural residues in India:

| Energy | Usage (ton) | Per capita consumption (kg) |

| Firewood | 252.1 million | 250 |

| Manure cakes | 106.9 million | 50 |

| Agricultural residues | 99.20 million | 134 |

Low utilization efficiency

India produces a lot of agricultural residues including rice husks, coffee husks, coconut husks, jute sticks, peanut husks, sawdust, etc., but they are not used properly and the utilization efficiency is low.

There are many disadvantages to using unprocessed agricultural residues as energy sources, such as:

- The calorific value is relatively low.

- The burning rate is difficult to control.

- It is difficult to mechanize continuous feeding.

- Large volume is required for storage.

Severe air pollution

In addition to the problems of transportation, storage and utilization, the direct combustion of bulk biomass results in very low thermal efficiency and extensive air pollution.

When the particulate matter (PM) emission in the flue gas exceeds 3000 mg/Nm2, the conversion efficiency is as low as 40%.

In addition, a large amount of unburned soot will be produced. As far as rice husk is concerned, carbon ash accounts for more than 40% of rice husk combustion. If about 2000 tons of rice husk are burned every day, about 800 tons of rice husk ash will be produced.

What is charcoal?

Charcoal is a dark brown or black porous solid fuel that remains after incomplete combustion of wood or wood materials or pyrolysis in the absence of air.

Common raw materials for making charcoal

Common raw materials for making charcoal:

- Various trees: beech, birch, oak, Castanopsis sclerophylla, elm, maple, poplar, linden, willow, masson pine, red pine, spruce, etc.

- Wood materials: coconut shell, sawdust, rice husk, bamboo chips, corn stalk, chestnut shell, walnuts, straw, sorghum residue, and other agricultural wastes.

Note that the carbonization of the biomass materials must be done by yourself. Then you can turn to us for crushing, grinding and briquetting.

What are charcoal briquettes?

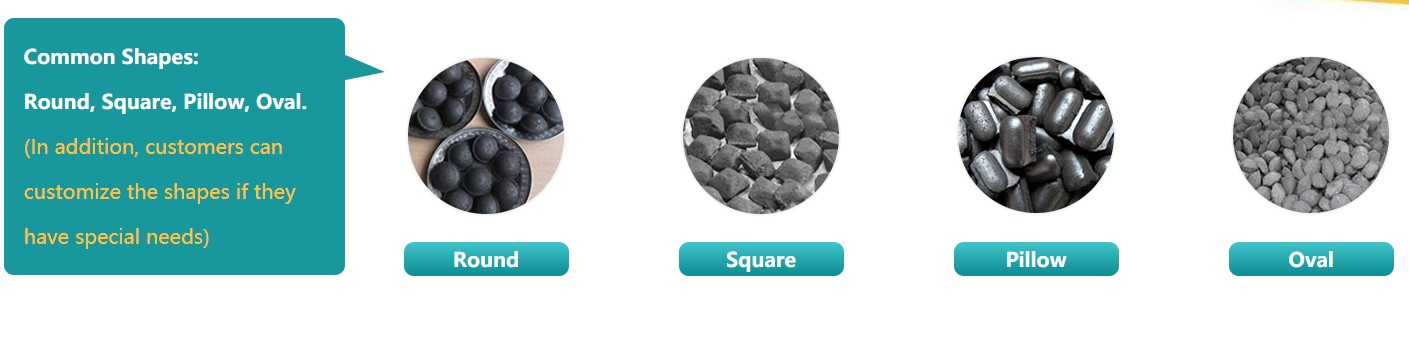

Charcoal briquettes are made from charcoal powder mixed with adhesives (starch, lime, etc.). They are pressed by a charcoal briquette machine into various shapes, such as round, square, pillow, and oval.

Different shapes of charcoal briquettes

What conventional fuels can charcoal briquettes replace?

- Diesel oil

- Kerosene

- Furnace oil

- Lignite

- Coal

- Firewood

What is the price of charcoal briquettes in India?

| Types | Price (USD/Kg) |

| Charcoal | 0.57-0.7 |

| Firewood | 0.24 |

| Charcoal briquettes | 0.2-0.4 |

The Dheeraj family from India originally used firewood as a household fuel. On the recommendation of their neighbors, they tried to use charcoal briquettes instead of firewood.

After a while, they were satisfied, "Charcoal briquettes can burn for a longer time, and the price is cheaper," Dheeraj said.

The following is a comparison of the weekly expenses of the Dheeraj family using firewood and charcoal briquettes:

| Types | Usage/ Weekly | Costs |

| Firewood | 4 bundles | $3.42 |

| Charcoal briquettes | 3 Kg | $0.64 |

His wife Nandana said, "When I cook with wood, a lot of smoke will irritate my eyes and give me a headache. This is not the case with charcoal briquettes.”

What are the advantages of charcoal briquettes?

- Charcoal briquettes are cheaper than petroleum, coal or lignite and are renewable resources.

- There is no sulfur in charcoal briquettes and no fly ash when burned, so it will not pollute the environment.

- Charcoal briquettes have a high calorific value (about 6592.52 Kcal/Kg).

- Charcoal pellets have a much lower ash content (2-10% compared to 20-40% of coal).

- Unified size and mass and more uniform combustion, without odor.

- Easy to handle, store and transport.

- Due to low moisture and high density, the boiler efficiency of charcoal briquettes is much higher.

- Charcoal briquettes ignite easily.

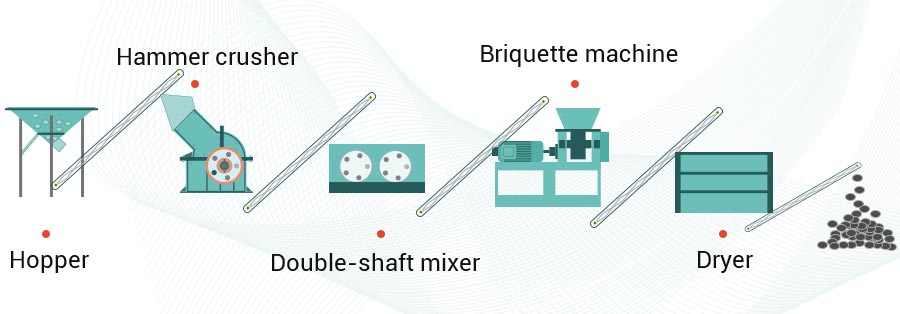

How to produce charcoal briquettes?

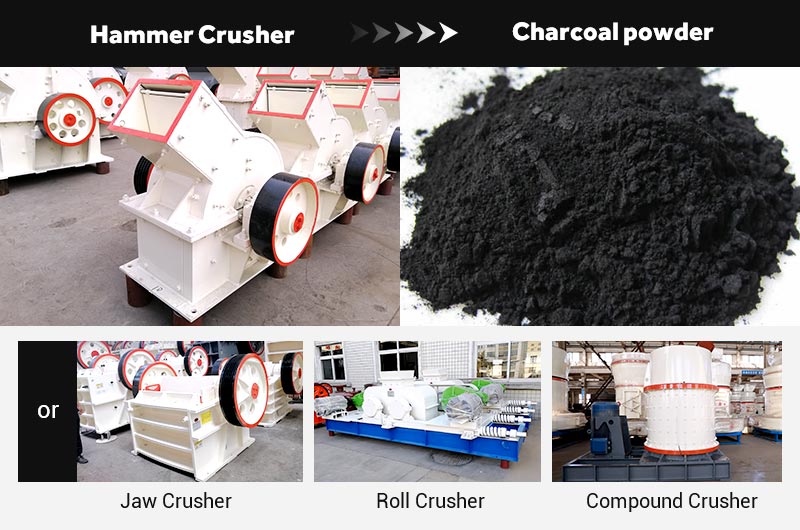

Step 1: Charcoal crushing

Crush the charcoal by a crusher to about 5 mm of charcoal powder. The smaller the particle size, the easier it is to be pressed into charcoal briquettes, and the higher the quality of charcoal briquettes.

Fote crushers to crush charcoal

Step 2: Add binders

It is often necessary to add binders before briquetting the charcoal powder to ensure the density, strength, hardness, and integrity of the charcoal briquettes during transportation.

There are three types of binders used in the production of charcoal pellets, namely inorganic binders, organic binders and composite binders.

Inorganic binders

clay, lime, cement, gypsum, water glass, etc.

Advantages: The process of making charcoal briquettes with the inorganic binder is relatively simple and the produced charcoal briquettes have higher compressive strength, compaction ratio and hydrophobicity.

Disadvantages: But due to the high ash content of inorganic raw materials, the ash content of the briquettes is slightly higher.

Organic binders

biomass binders (such as starch, cassava pulp, waste paper pulp, molasses, cow dung), tar, bitumen, lignosulfonate binders and polymer binders.

Advantages: The briquettes made by the organic binder have low ash content.

Disadvantages: poor thermal strength.

Composite binder

The composite binder is composed of two or more kinds of organic and inorganic binders.

Advantages: The briquettes have low temperature, hot strength and low ash content.

Disadvantages: The preparation process is more complicated, and the cost is relatively high.

Step 3: Stir and mix

The charcoal can be sent to the briquetting machine for molding after being mixed in the mixer. The more fully stirred, the higher the quality of briquettes produced.

Step 4: Dry in the dryer

The materials should generally be fed into the dryer evenly and continuously before the briquette is pressed. The main body of the dryer is a slightly inclined and rotatable cylinder.

The hot air generated by the hot blast stove or steam boiler is passed into the dryer to contact the wet charcoal.

Fote rotary drum dryer for drying charcoal

The cleaning device inside the dryer, crushing and dispersing device, etc., turns over, pushes and strengthens the heat exchange of wet charcoal. Finally, it can be dried into a loose product with the moisture of less than 12%.

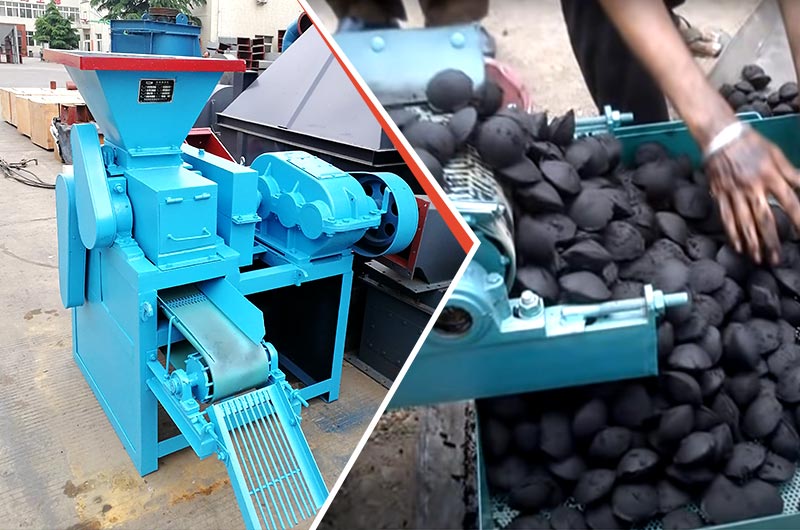

Step 5: Briquette making

The mixed materials are fed into the briquetting machine. It has a pair of cylindrical wheels with axes parallel to each other, the same diameter, that rotates at the same speed and in opposite directions.

There are many hemispherical sockets of the same shape and size regularly arranged on the wheels.

Fote briquettes making machine with favorable price

The material falls between the two wheels. Driven by the motor, the sockets are gradually closed. Under the action of high temperature and high pressure, the material in sockets is pressed into briquettes.

Then the sockets are gradually separated, and the compressed charcoal briquettes fall off smoothly.

The information of charcoal briquetting machine is shown in the following table:

| Raw material size (mm) | ≤5 |

| Moisture content of raw materials | <12% |

| Size of briquettes | Adjustable |

| Capacity (TPH) | 1-50 |

| Capacity of charcoal briquettes production line (TPH) | ≤100 |

| Shapes of briquettes | Square, oval, pillow, etc. |

| Working environment | Dust-free |

Step 6: Packaging

Pack and sell the compressed charcoal briquettes in sealed plastic bags.

Charcoal briquettes making plant

What are the uses of charcoal briquettes?

Household

Charcoal briquettes can be used not only for boiling water, cooking, family barbecue, heating, but also for deodorization, dehumidification, garden composting and so on.

Business

Catering institutions such as restaurants, canteens, bakeries, wineries, etc. can use charcoal briquettes to boil water, cook and grill.

Charcoal briquettes can also be used for baking tobacco, tea, oil and so on.

Industry

- Used for making tiles, firing pots and ceramics, etc.

- Used as a special filler for construction concrete, insulating material, refractory material, etc.

- Used as fuel for industrial boilers, gasifiers, etc., to generate heat and steam.

- Used as a carburizing agent for smelting high quality nonferrous metals, cast iron and machinery parts.

Agriculture

Charcoal briquettes can improve soil temperature, pH value, maintain soil moisture, and absorb harmful metals, or be used as a slow-release agent for organic fertilizers.

Animal husbandry

Charcoal briquettes can be used as fuel for hatching chicks, as well as feed additives and deodorants.

Is it profitable to invest in charcoal briquettes projects?

The main costs of investing in a charcoal briquettes project are as follows:

| Fixed costs | Equipment investment |

| Venue rental | |

| Labor cost | |

| Variable costs | Raw material investment |

| Electric charge | |

| Maintenance and repair costs | |

| Transportation cost | |

An Indian charcoal briquettes producer produces 960 tons of charcoal briquettes per year. The following table shows his costs and benefits:

| Items | Value (USD/Yr.) |

| Fixed costs | 6000 |

| Variable costs | 17000 |

| Total investment | 25000 |

| Gross annual income | 40000 |

| Payback period | Within 8 months |

Conclusion

Agricultural by-products not only cause waste of resources, but also cause serious environmental pollution.

Charcoal briquettes with both economic benefits as well as social benefits

Using these agricultural by-products to make charcoal and then make charcoal briquettes is an economically viable and environmentally friendly solution for an agricultural country like India, which produces a large number of agricultural wastes every year.

Investing in the production line of charcoal briquettes can bring economic benefits as well as social benefits.