Charcoal briquettes are pellets formed by mixing binder and fine charcoal powder through briquetting technology. One of the uses of charcoal briquettes is grilling. This article will introduce in detail the production process of charcoal briquette and how to use it for barbecue.

Charcoal briquettes: pellets made by briquette machine

Why is charcoal briquette better than lump charcoal?

Charcoal, the ideal fuel for barbecue, can burn stably and cleanly. Charcoal comes in two types: lump charcoal and charcoal briquettes. The following will take you through these two types of charcoal to help you make the right choice.

Lump charcoal

Lump charcoal, also known as natural charcoal or hardwood charcoal, is charred wood formed by kiln carbonization of waste wood or branches from factories and wood companies.

Lump charcoal or natural charcoal for grilling and BBQ

Advantages:

- Fast ignition speed.

- Higher burning temperature (1400°F).

- No additives and binders (all natural).

Disadvantages:

- The size and density of lump charcoals are not uniform, so their burning temperature is not consistent, which affects cooking time.

- Faster burning and larger consumption.

- Higher price.

- The bag may contain too much dust to prevent burning.

- It is easily broken into unusable scraps.

- Not every piece is completely carbonized.

Charcoal briquettes

Charcoal briquettes, the most popular barbecue fuel currently, are mainly made by charcoal briquetting machine. Their ingredients are charcoal, a small amount of sawdust, white ash, binder, etc. Coming in different shapes, charcoal briquettes generally burn at 800 to 1000 °F.

Charcoal briquette is the most popular barbecue fuel.

Advantages:

- Longer burning time.

- Stable temperature.

- Lower price than lump charcoal.

- Lighter and more convenient.

- Great for grilling and barbecuing.

Disadvantages:

- Not easy to ignite.

- Produce chemical odor.

- Produce ash.

Even though lump charcoal has its advantages, charcoal briquettes are still the best choice in the charcoal industry. They are convenient, cheap and consistent in size.

You don't need superb grilling skills, so it is a great choice for smoking and grilling. Charcoal briquettes are strongly recommended for any level of cooks, especially for beginners.

How to make charcoal briquette?

Is charcoal briquette safe? Let's take a look at its production process. Charcoal briquettes need to be made with a reliable charcoal briquette machine. The following is briquette production process of a professional charcoal briquetting machine brand Fote:

Raw materials → carbonization → crushing and drying → briquetting → drying, packaging and warehousing.

Step 1 Preparation of raw materials

First, you need to collect raw materials.

Various raw materials can be made into charcoal briquettes, such as logs, pine, birch, oak and other trees; straw, rice husk, coconut shell, corn stalk, bamboo chips, sawdust, sorghum residue, and other agricultural wastes.

Step 2 Carbonization process

The raw materials are fed into a carbonization furnace and heated to about 1,100°F (590°C).

Then they are carbonized under anhydrous, oxygen-free, high temperature and high-pressure conditions.

Please note that the carbonization work must be done by yourself. We don't sell such furnaces.

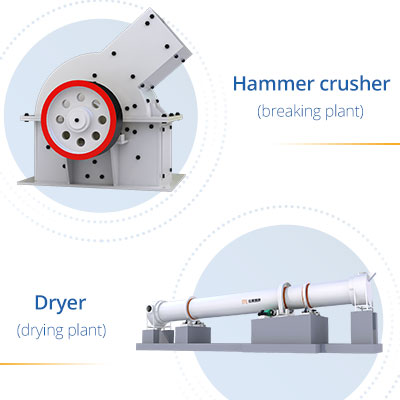

Step 3 Crushing and drying

Before briquetting, the raw materials need to be pretreated. The hammer crusher is suitable for crushing logs with a diameter of less than 200 mm. After grinding, the output diameter is 3-5 mm.

The dryer machine can reduce the moisture content of the raw materials to 12%-15%, and control the raw materials to the required state.

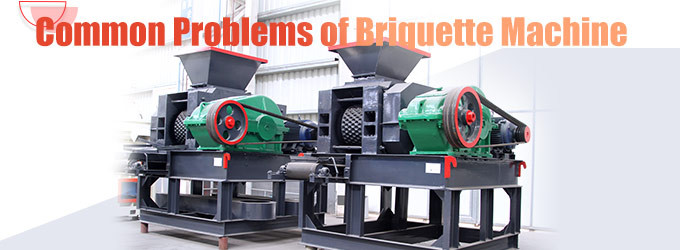

Step 4 Briquetting process

The charcoal briquetting machine is the core equipment.

Due to the combined action of moisture, binders (such as starch), temperature (about 105°F or 40°C) and roller, the briquettes can maintain their shape when they fall from the bottom of the ball press.

Step 5 Drying and packaging

Bag them for storage, transportation and sale.

Bag them for storage, transportation and sale.

For family barbecues, you can directly buy charcoal briquettes sold in bags. Don't be greedy for cheap charcoal. You should choose mechanism charcoal briquettes from regular brands as much as possible.

Of course, if you need a charcoal briquette machine, please contact us directly.

How to prepare/clean BBQ grills before grilling?

- 1Empty the ashes in the grill. Empty the ashes, used charcoal briquettes or grease at the bottom of the grill. Charcoal combustion requires oxygen, so make sure that the vents are unobstructed.

- 2Preheating. Heat the oven for at least 30 minutes to burn off the residue from the last grill.

- 3Clean the grate. Turn off the oven before starting to scrub the grill. Then use a wire brush or a damp cloth to clean the rust or residue on the grille.

How should you arrange your charcoal briquettes?

The snake method (an indirect grilling method) can control the temperature of briquettes well and extend cooking time (4-20 hours), which is a simple and effective method.

1 Lay the first row of charcoal along the inner wall of the grill. Each briquette is next to adjacent one to form a two-row wide semicircle or large C shape.

Two rows of cahrcoal briquettes in the grill

2 Lay the second row inside the first row, ensuring that the two rows of charcoal briquettes are next to each other.

3 Place another row of charcoal briquettes on top of them. It takes about 1 pound of charcoal briquettes for every pound of cooked food.

4 Several pieces of applewood can be placed above the charcoal briquettes, which can increase the flavor of meat when burning. Or place fresh wet herbs (such as rosemary, thyme or bay leaf) on charcoal.

The snake method of bbq

How to light charcoal briquettes?

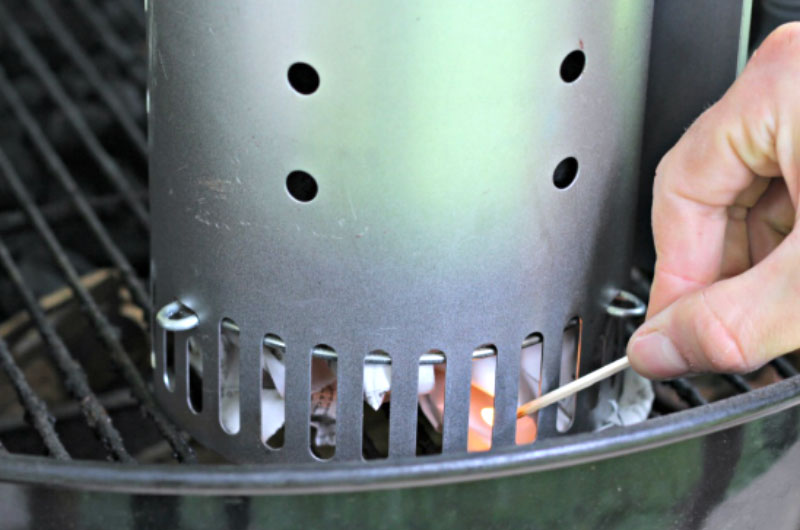

The easiest and most thorough way to ignite charcoal briquettes is to use a chimney starter.

1 Place a few crumpled newspapers at the bottom of the chimney starter, then turn it upside down to fill some charcoal briquettes.

Newspapers at the bottom of the chimney starter

2 Place the chimney lighter in the center of the charcoal grate, and light the newspaper with a long lighter or match through the hole at the bottom of it. When the newspaper burns below, the flame will light the charcoal briquettes above.

Light the newspaper

3 Keep the chimney starter in place until the charcoal is completely ignited (about 20-30 minutes). When there is a layer of white ash on the surface of charcoal, it means that it is completely ignited.

Ignite the charcoal there is a layer of white ash

4 Pour these lighted charcoal briquettes into the grill and place them on one end of the snake with tongs. This will continue to light adjacent briquettes. The gradual lighting of the charcoal provides you with a constant low and controlled temperature over a long period of time.

Lighted charcoal briquettes on one end of the snake

How do you BBQ with charcoal briquettes?

1 Place a disposable aluminum foil water pan containing half or three-quarters of hot water in the snake-shaped charcoal.

Aluminum foil water pan in the snake

2 Put the grate into the grill, open the upper and lower vents, and close the lid until the temperature reaches 250-300 degrees Fahrenheit.

3 Place the food on the grate above the water pan and close the lid. Check the thermometer every hour to keep the temperature between 250 - 300 degrees Fahrenheit. You can control the fire by opening the vents to increase the temperature, or closing the vents to lower the temperature, but never completely close the vents.

Put meat on the grate

4 Poke the meat with a fork. If the inside is pink, let it still on the grill for a while.

How to put out charcoal briquettes after grilling?

1. Cool the charcoal briquettes and grills

Cover the lid of the grill and close its top and bottom vents. Wait 48 hours until the charcoal is extinguished and the grill is completely cooled. If time is tight, you can put sand on charcoal briquettes to extinguish it and wait for it to cool.

2. Discard waste charcoal and ashes

Wrap the used charcoal and ashes in aluminum foil to eliminate the possibility of re-ignition. Throw it in a non-flammable outdoor trash can (preferably a metal container).

Discard waste charcoal and ashes

3. Clean the grills

Clean the grills, vents and chamber with a wire brush or metal scraper for next use.

Clean the grill

4. Recycle charcoal briquette

Put the unburned charcoal briquette that can be used next time back into the grill with metal tongs, or store it in a fireproof container for the second use.

All you need for a barbecue

- Charcoal grills

- A bag of charcoal briquettes

- Condiments: olive oil, salt, black pepper, etc.

- Marinated meat: pork, poultry, fish, turkey, etc.

- Probe thermometer to detect whether the food is cooked.

- Oven/BBQ thermometer

- Chimney starter

- Long lighter or match

- Long handle pliers

- Disposable foil pot or drip pan, absorbing absorb heat to keep the grill temperature stable and increasing water vapor to improve the flavor of the meat.