Coal is still an important fuel for power plants, cement factories, steel production, and other industries. To use coal efficiently, we must grind raw coal into pulverized coal powder.

That's where the coal pulverizer comes in.

What is a coal pulverizer?

A coal pulverizer, also known as a coal mill, is an industrial grinder that crushes and grinds coal into fine powder.

Pulverized coal burns more completely and efficiently than raw coal. It helps reduce fuel waste and emissions in boilers and kilns.

Modern coal pulverizer machines can process many coal types:

- Anthracite: High carbon, low moisture, used in metallurgy and high-heat applications

- Bituminous coal: Commonly used in power station boilers

- Sub-bituminous and lignite: High moisture content; need drying during grinding

- Others: Coking coal, petroleum coke, coal gangue, and fly ash

No matter the coal hardness or moisture content, we offer the right coal mill solution for efficient grinding.

Three types of coal pulverizers

In modern coal powder preparation systems, the coal pulverizer plays a key role.

The most common types of coal grinding machines include:

- Vertical coal pulverizer (Vertical roller mill)

- Air-swept coal mill

- Ball mill for coal

Vertical coal pulverizer (Vertical roller mill)

The vertical coal pulverizer is the top choice for coal powder plants, power stations, steel factories, and building materials production. It is a multi-functional coal mill that integrates drying, grinding, classifying, and conveying in a single system.

It can process wet coal (moisture content ≤15%), such as lignite and bituminous coal. The finished pulverized coal powder can reach up to 400 mesh in fineness.

Compared to traditional ball mills and air-swept coal mills, it offers lower energy consumption, smaller footprint, and finer grinding, making it suitable for energy-saving and environmentally friendly coal pulverization plants.

- Energy-saving: 30–40% lower power consumption than ball mills

- Vertical structure: Saves coal powder plant space

- High grinding precision: Over 90% of powder passes through 38μm sieve

- Capacity: 6–80 t/h

Best-selling vertical coal pulverizer models: Get a quote

| Model | Capacity (t/h) | Main motor (kW) |

| HLM1200M | 6–10 | 110–132 |

| HLM1700M | 20–30 | 280–355 |

| HLM2400M | 45–55 | 560–710 |

Air-swept coal mill

The air-swept coal mill, also called a coal pulverizing mill, uses hot air flowing through the mill to dry and grind coal at the same time.

This coal pulverizer machine can handle different types and hardness levels of coal, from lignite to anthracite. The final pulverized coal powder is about 200 mesh (75μm).

Working principle: grinding + drying in one

- 1 Feeding: Raw coal is fed into the coal pulverizer through the feeding system.

- 2 Hot air inlet: Hot air (about 300°C) enters the pulverizer mill through a special air duct.

- 3 Drying: Special lifting plates elevate the raw coal, enabling intense heat exchange with the airflow to remove moisture.

- 4 Grinding: The dried coal moves into the grinding chamber. Steel balls grind the coal into fine powder.

- 5 Separating and collecting: A draft fan pulls the coal powder and air mixture out of the mill. Oversized particles are returned to the coal grinder for re-grinding.

Best-selling air-swept coal mill models: Get a quote

| Model | Capacity (t/h) | Main motor (kW) |

| Φ1.7×2.5 | 3–5 | 95 |

| Φ2.6×(5.25+2.25) | 13–14 | 400 |

| Φ3.2×(6.75+2) | 25–30 | 710 |

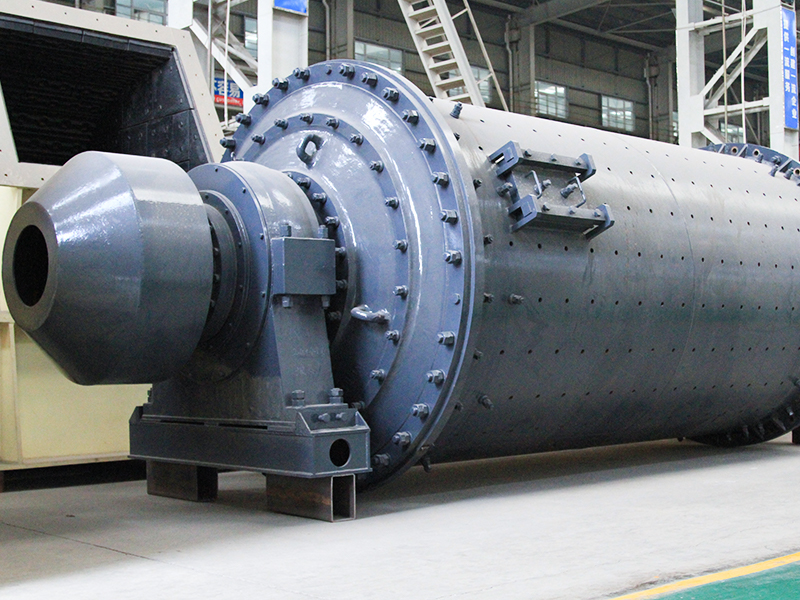

Coal ball mill

A ball mill is a traditional coal pulverizer used to grind both dry and slightly wet coal (moisture ≤6%). It can handle hard coals like anthracite and bituminous coal.

This coal grinder is ideal for large-scale coal powder plants that need to run 24/7. It offers continuous, high-capacity performance with output ranging from 1 to 600 tons per hour.

When used with an efficient separator, the coal ball mill allows for precise control over the final pulverized coal powder size.

- Separator capacity: 25–300 t/h

- Classification efficiency: Over 92%

- Adjustable fineness: Simply adjust the airflow speed—higher airflow = finer powder, lower airflow = coarser powder

Best-selling coal ball mill models: Get a quote

| Model | Capacity (t/h) | Main motor (kW) |

| Φ2100×3000 | 6.5–36 | 155 |

| Φ2400×4500 | 8.5–60 | 320 |

| Φ2700×4500 | 26–90 | 480 |

Note: While a coal ball mill is effective for grinding, it does not include a built-in drying system. If the coal has high moisture content, additional drying equipment is needed. This results in a longer process, higher energy use, and more system investment.

That's why many modern pulverizer mill systems now prefer air-swept coal mills or vertical coal mills, which combine drying and grinding in one unit.

Pulverized coal production line solution — From raw coal to boiler fuel

A typical configuration for a coal powder production plant includes:

1. Coal crusher

Crushes raw coal into ideal particle size for feeding into the coal mill.

2. Feeding system

Automatically delivers crushed coal to the grinding mill, ensuring continuous and stable operation.

3. Coal grinding system

The core part of the production line. Optional solutions include:

- Air-swept coal mill: Suitable for simultaneous drying and grinding.

- Vertical coal mill: Ideal for high-moisture coal; energy-saving and stable.

- Coal ball mill: large output

4. Classifier & dust collection

Fine coal powder is separated and collected. Coarse particles are returned for further grinding.

5. Powder storage & transport system

The pulverized coal is transported to silos for use in industrial boilers, kilns, or furnaces.

Why choose FTM Machinery's coal mills?

- Efficient coal powder grinding performance

- Suitable for all coal types, including high-moisture coal

- Ideal for power plant applications

- Lower energy use, reduced maintenance, longer service life

Talk to our coal grinding experts

Whether building a new plant or upgrading an existing system, our team helps you choose the right coal mill — including vertical mills, air-swept mills, or ball mills — based on your needs.

FAQs

1. What is the need for coal pulverization?

- 1. Improves combustion efficiency: Fine coal powder has a larger surface area, making it burn more completely.

- 2. Reduces energy waste: Pulverized coal releases heat more effectively, lowering overall energy consumption.

- 3. Meets boiler requirements: Modern industrial and power plant boilers require fine coal for stable and efficient burning.

- 4. Supports environmental goals: Complete combustion of fine coal reduces smoke, CO, and unburned carbon emissions.

2. How to choose the right coal mill?

- When selecting a coal mill, consider the following:

- 1. Coal type: For high-moisture coal, a vertical coal mill is recommended as it offers good drying performance.

- 2. Capacity: For small output, choose an air-swept coal mill. For larger capacity, go with a vertical mill or ball mill.

- 3. Required fineness: For boiler use, coal powder should typically pass 200 mesh ≥75%. A classifier can be added to improve fineness control.

- 4. Energy use & maintenance: For long-term use, choose mills with high efficiency and low maintenance, such as vertical coal mills.