What is fly ash?

Fly ash is a fine powdery by-product generated from coal combustion in power plants. It is carried by flue gas and collected by dust removal systems such as electrostatic precipitators or bag filters.

Its main components include silica (SiO₂), alumina (Al₂O₃), iron oxide (Fe₂O₃), and calcium oxide (CaO), along with a small amount of unburned carbon.

Based on the collection method, fly ash can be divided into two main types:

- Dry fly ash: Collected by electrostatic or bag filters. It has low moisture content and is easy to handle.

- Pond ash (Wet fly ash): Transported with water and settled in ash ponds. It has high moisture content and must be dewatered and dried before reuse.

Each type of fly ash requires a different handling process for efficient reuse.

Fly ash drying

Fly ash drying is a necessary step before grinding, pelletizing, beneficiation, or mixing with cement.

Many types of fly ash, especially pond ash, contain 15–60% moisture. Drying reduces moisture to below 5%, improving storage, transport, and processing efficiency.

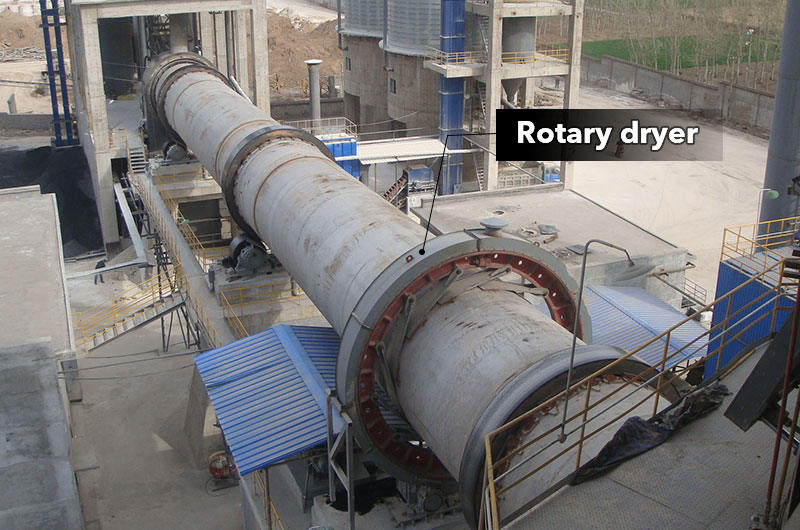

A rotary drum dryer is the most reliable and widely used equipment for fly ash drying. It can operate with direct or indirect heating and supports capacities from 2 to 70 tons per hour.

Advantages of rotary dryers: Get a quote

- Suitable for fly ash, bottom ash, pond ash, and industrial residues

- Final moisture can be as low as 1% or fully dried.

- High fuel efficiency; drying completed within several minutes

- 30–40% lower energy consumption than traditional systems

- Fully sealed feeding and discharging ports to minimize dust and heat loss

Fly ash grinding

Grinding increases the fineness and surface area of fly ash. In the cement industry, fly ash is often used to replace 10–30% of Portland cement, improving concrete performance and reducing production costs.

Common fly ash grinding machines: Get a quote

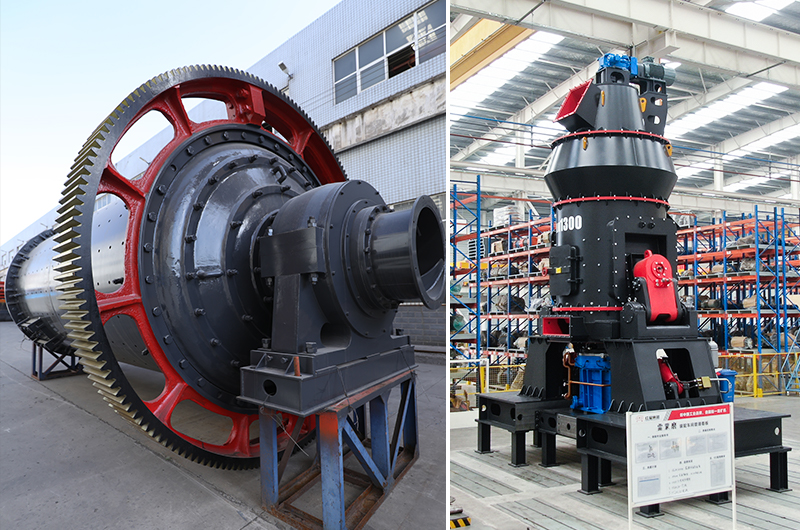

- Ball mill: A traditional grinding option with a simple structure, suitable for large feed sizes and small to medium-scale production.

- Vertical grinding mill: Suitable for large-scale production. It combines grinding, drying, and classification, supports continuous operation, and consumes less energy per ton.

With hydraulic and drying systems, the vertical roller mill offers higher capacity and finer output compared to a ball mill, while reducing energy consumption by 30–50%.

| Equipment | Capacity (t/h) | Fineness (mesh) |

| Ball mill | 2–280 | 20–200 |

| Vertical grinding mill | 8–420 | 375–1250 |

If you run a small or medium plant, a ball mill and a classifier setup is more cost-effective. For large continuous plants, the vertical mill is the preferred choice due to higher capacity and lower power cost.

Fly ash pelletizing

Fly ash pellets are made from about 85% fly ash, mixed with lime, gypsum, and binders. These fine powders are agglomerated into 2–10 mm particles using a disc pelletizer.

Fly ash pellets are light, strong, corrosion-resistant, heat-insulating, and frost-resistant. They are commonly used for:

- Lightweight concrete aggregate

- Building bricks and blocks

- Insulation materials or fuel balls

The disc granulator is suitable for small to medium production, and the pellet size can be adjusted by changing the speed and angle.

Fly ash beneficiation (Deep processing)

For industries requiring high-purity and highly active fly ash, wet beneficiation and modification processes can be applied.

1. Slurry preparation and carbon removal

Mix dry fly ash with water to form a slurry. Add a frothing agent and perform flotation to remove unburned carbon, reducing carbon content to below 1%.

2. Magnetic separation

Use a wet magnetic separator to remove iron-rich and magnetic particles, significantly improving the whiteness and chemical purity of the product.

3. Wet grinding

Apply a ball mill to reduce particle size below 325 mesh, increasing surface area and pozzolanic activity.

4. Surface modification and dying

Add lime or dispersants during grinding to coat the particle surface and improve reactivity. Finally, dry the product at low temperature to obtain fine, high-purity fly ash.

Processed fly ash with these methods is carbon-free, iron-free, and ultra-fine—suitable for high-performance concrete, ceramics, catalysts, and premium mineral fillers.

| Category | Core process | Typical product | Suitable clients |

| Basic treatment | Drying + Grinding | Standard fly ash additive | Cement & building material plants |

| Resource utilization | Drying + Pelletizing | Fly ash bricks, blocks | Construction material plants |

| Advanced purification | Flotation + Magnetic Separation + Wet Grinding + Drying | Pozzolanic material, industrial filler | New material companies, research institutes |

Start your fly ash processing project

Looking to build a complete fly ash processing line? FTM Machinery provides professional solutions for drying, grinding, and beneficiation systems.

Contact our engineers today for a customized design and quotation.