Not all gold ores are the same. Some are hard rock deposits locked in quartz veins, others are alluvial (placer) gold found in riverbeds, and many are oxidized gold ores that require special treatment.

Gold mining is not just about digging—it's about efficient grinding and processing to maximize recovery.

Why grinding is critical in gold mining

Once the gold ore is crushed, it must be ground into fine particles so that recovery methods like flotation, gravity separation, or cyanidation can work effectively.

- Finer grinding = higher gold recovery

- Different ores are suitable for different gold mills

- Bad equipment will cause gold losses and high energy use

This is why choosing the right gold mill is essential for your project's success.

Among all options, the two most popular solutions are the gold ball mill and the gold wet pan mill—each designed for specific mine types, capacities, and budgets.

Gold ball mill

The powerful grinding capacity of the gold ball mill makes it widely used not only in large and medium-sized gold mining companies in the United States and Australia, but also in major gold-producing regions of Africa, such as South Africa and Ghana.

It can process 1–615 tons of gold ore per hour, with a final output size of 20–200 mesh (0.074–0.089 mm). Gold ball mill is especially suitable for fine grinding of hard rock gold ore before chemical extraction.

The gold ball mill can grind almost all common types of gold ores, including:

- Quartz vein gold ore – hard and fine-grained, requires fine grinding.

- Oxidized gold ore – brittle, grinding improves leaching efficiency.

- Sulphide gold ore (pyrite, arsenopyrite, etc.) – needs grinding for gold liberation.

- Alluvial / black sand gold ore – grinding helps separate gold from other minerals.

- Mixed-type gold ore – contains both oxide and sulphide, requires stable grinding performance.

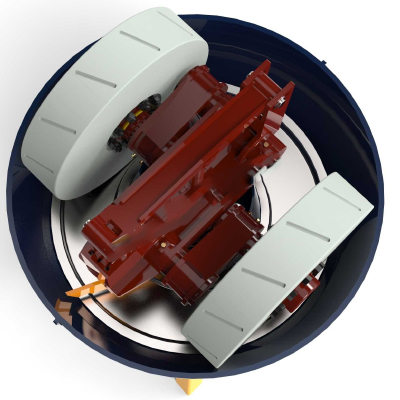

Working principle: The gold ball mill is driven by a motor that rotates the cylinder. Steel balls inside are lifted and dropped, producing impact and grinding force to crush the ore into fine powder. Qualified material is discharged, while oversized particles are returned for further grinding.

Gold ball mill advantages:

- Suitable for continuous gold ore grinding in different scales

- Stable fine grinding performance, improving gold recovery

- Strong cylinder, wear-resistant liner, long service life

- Rolling bearings reduce energy consumption by 15–20%

- Closed system design, less dust, more eco-friendly

We offer large, medium, and small gold ball mill machines. Get a quote

| Model | Capacity (t/h) | Main motor (kW) |

| Φ1500×5700 | 3.5–6 | 130 |

| Φ2200×7000 | 15–28 | 380 |

| Φ2700×4500 | 26–90 | 480 |

Gold wet pan mill

The gold wet pan mill, also called wet grinding mill, is mainly used for secondary grinding after the first crushing of gold ore. Its capacity is 1–50 tons per hour, and it can grind gold ore to 100–150 mesh (0.100–0.147 mm).

The mining mill is very popular in small and medium-sized mines in Tanzania, Kenya, Peru, Philippines and Indonesia. Thanks to its simple structure and low price, it is especially suitable for oxidized gold ore and alluvial gold deposits with lower production.

Working principle: The gold wet pan mill is driven by a motor that makes the round grinding pan rotate slowly. Two heavy rollers inside the pan repeatedly crush and grind the ore while mixing it with water into slurry. During this process, the gold ore becomes finer and more uniform. If mercury is added, the mill can grind and amalgamate gold at the same time, improving recovery with a simple operation.

Gold wet pan mill advantages:

- Easy to operate, only basic training needed

- High-manganese steel grinding rings for minimal gold loss

- Energy-saving, works well even in areas with limited electricity

- Can complete grinding and amalgamation in one step

Popular models of gold wet pan mill: Get a quote

| Model | Speed (r/min) | Power (kW) |

| Φ1100 | 17–19 | 7.5 |

| Φ1500 | 19–21 | 22 |

Customer case: gold ball mill application in a Zimbabawe gold mine

In a medium-sized gold mine in Zimbabawe, the customer adopted a crushing–ball mill–mineral processing production line:

- 1 Primary crushing: Jaw crusher breaks large gold ore into pieces smaller than 150 mm.

- 2 Secondary crushing: Cone crusher further crushes the ore to below 20 mm for ball mill feed.

- 3 Grinding: The ore enters the Ф2200×7000 gold ball mill, processing 25 tons per hour, with the final particle size reaching 0.074 mm.

- 4 Mineral processing: The ground slurry enters gravity separation and cyanidation circuits, significantly improving gold recovery.

After actual operation, the gold ball mill showed stable performance, low energy consumption, and easy maintenance. The customer reported a 15% increase in final gold recovery, meeting the requirements for continuous production.

Customized solutions for gold ore grinding machines

We offer small, medium, and large gold ball mills and wet pan mills, with customized solutions based on gold ore type and production capacity.

- 40+ years in gold ore grinding machine manufacturing

- Exported globally to Africa, South America and Southeast Asia

- Full range of models for small to large gold mines

- Reliable after-sales support

For a quote or technical solution, please contact our sales team. Contact us

FAQs

1. What is the price of a gold grinding mill?

- The gold ball mill price usually ranges from a few thousand to over one hundred thousand USD, depending on capacity, model, and motor power. It has higher efficiency, longer service life, and better grinding performance. For customers who need stable production and higher gold recovery, the ball mill is the best choice.

- The gold wet pan mill price is much cheaper, usually only a few thousand to tens of thousands USD. However, compared with the gold ball mill, its capacity and grinding fineness are very limited.

2. Can I use a gold ball mill and a gold wet pan mill together?

- Yes. You can use a wet pan mill for initial grinding and then a gold ball mill for finer grinding. This combination improves efficiency and increases gold recovery, suitable for both small and large mining operations.