Gold rarely occurs in its pure, metallic form — it is usually locked within hard rock and minerals. To extract it, mining companies use rock crushers (also known as gold ore crushers or ore crushing machines) to break large chunks of ore into smaller, manageable pieces for further processing.

In hard rock gold mining, a portable rock crusher brings the crushing operation directly to the ore source, eliminating the need for costly material hauling.

Why portable rock crushers are essential for gold mining

Gold deposits are often found in remote, rugged terrains. Traditional fixed crushing plants require hauling ore over long distances, increasing fuel costs, labor, and processing time.

Portable rock crushers solve this by bringing the crushing plant directly to the mining site.

Key advantages of using portable rock crushers for gold mining:

- Lower transportation costs & fuel savings — crush ore where it is mined.

- Faster turnaround from extraction to processing — reduces delays and speeds up gold recovery.

- Mobility between pits or mining sites — ideal for multi-site operations.

- Scalable capacity — from small-scale pilot plants to large-scale hard rock gold processing plants.

Our crushing stations can be equipped with different primary and secondary crushers — jaw, cone, or impact — to match your ore characteristics and production goals.

Whether you need a portable rock crusher for gold mining, or a crusher for a hard rock gold processing plant, we design equipment that delivers reliability, efficiency, and maximum recovery.

Types of rock crushers for portable platforms

Our portable rock crushers for gold mining come in two chassis types: track-mounted and wheel-mounted. You can choose the option that best fits your mining site.

Once the chassis is selected, you can equip the platform with different types of gold crushers depending on ore characteristics and production requirements.

1. Portable jaw rock crusher

A robust primary crusher designed for the first stage of gold ore processing. The jaw crusher excels at handling large, hard rock gold ore, ensuring reliable reduction before secondary crushing.

Common jaw crusher models: HD86, HD98, HD110, HD125

Capacity: 85–650 t/h

Maximum feed size: ≤800 mm

Output size: 50–225 mm

Portable jaw rock crushers for sale Get a quote

2. Portable cone rock crusher

Designed for secondary and tertiary crushing, the cone crusher produces finely crushed, uniform material ideal for milling or leaching in gold processing plants.

Portable cone crushers are often paired with jaw crushers in two-stage crushing setups. Available in single-cylinder, multi-cylinder, and fully hydraulic configurations to meet varying production demands.

Common cone crusher models: HPM200, HPM300, SC250

Capacity: 90–400 t/h

Maximum feed size: ≤250 mm

Output size: 3–40 mm

Portable cone rock crushers for sale Get a quote

3. Portable impact rock crusher

This gold crusher is used to make even, cube-shaped stones from medium-hard to hard gold ore. It works best with ores that have low silica content.

It is very good for making material for heap leaching or for direct processing, with less fine powder.

Common impact crusher models: PF1214, PF1315, HD1110, HD1315

Maximum feed size: ≤700 mm

Capacity: 70–280 t/h

Weight: 39–62 t

Portable impact rock crushers for sale Get a quote

Additional options and features

Closed-circuit screening

Portable rock crushers can be combined with vibrating screens to precisely control the output size, making the material suitable for heap leaching, milling, or further processing.

Maintenance and wear parts

Key wear parts such as jaw plates, cone liners, and impact hammers are easy to replace, reducing downtime and keeping production on track.

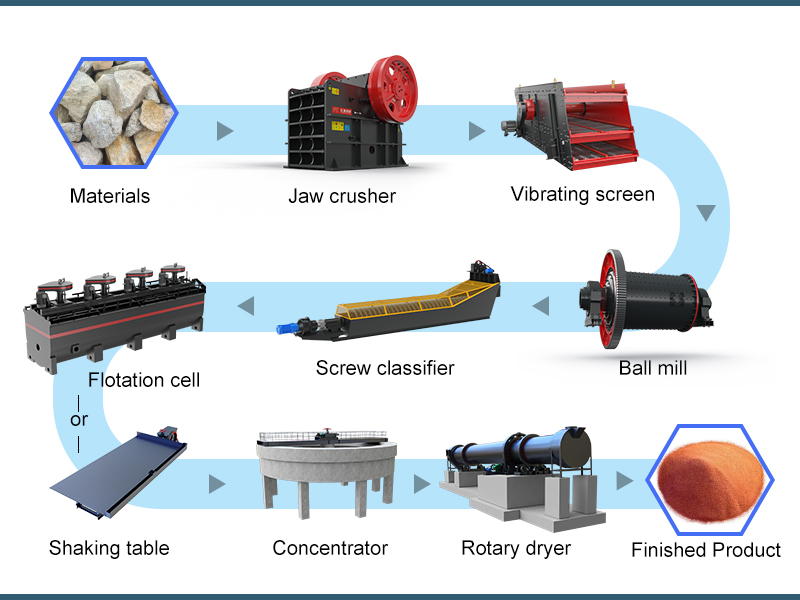

Working with hard rock gold processing plants

A portable rock crusher for gold mining is usually the first step in a complete hard rock gold processing plant. After crushing, the material can be sent to gravity separators, shaking tables, or flotation systems for further gold recovery.

- Gravity separation – using shaking tables or centrifugal concentrators to recover coarse gold.

- Flotation – ideal for gold ores with high sulfide content.

- CIP/CIL (Carbon in Pulp / Carbon in Leach) – for fine, disseminated gold, combining leaching and adsorption in one process.

Our engineering team can design a complete hard rock gold processing plant, integrating portable crushing equipment with screening, grinding, beneficiation, and recovery systems — all tailored to your mine.

Contact us today to discuss your gold processing needs and get the right solution for your operation.

Portable rock crusher buying guide

When investing in a gold crusher for gold mining, choosing the right machine for your site and ore type is critical for efficiency and long-term performance.

Here's what you should evaluate before making a purchase:

1. Ore type & hardness

Different gold ores vary in hardness, abrasiveness, and silica content. Select a crusher type and strength that matches your ore:

- Hard rock gold ores (e.g., quartz veins) require heavy-duty jaw or cone crushers.

- Medium-hard ores can be processed efficiently with impact crushers.

2. Production capacity

Estimate your required throughput in TPH (tons per hour). Oversizing can waste fuel and increase costs, while undersizing can limit your gold recovery potential.

3. Wheeled and tracked types

- Wheeled portable crushers – easier to move on roads between sites, lower initial cost.

- Tracked portable crushers – better traction and maneuverability on uneven or muddy terrain, ideal for remote gold mining areas.

4. Power source

Choose the power option that suits your site's infrastructure:

- Diesel engine – best for remote mining locations with no access to the electrical grid.

- Electric motor – efficient and cost-effective in areas with stable electricity supply.

- Hybrid systems – combine diesel and electric for flexibility and fuel savings.