In today's fast-paced construction, mining, and recycling industries, mobile crushing has emerged as a powerful alternative to traditional stationary or fixed rock crushing machines. With the ability to move between crushing sites, mobile crusher plants are transforming the way rock and mineral materials are processed.

Whether you are looking for a mobile jaw crusher, a mobile rock crusher, or a portable rock crusher for a remote mining site, mobile crushing offers flexibility, speed, and cost savings.

What is mobile crushing?

The mobile crushing equipment is the rock crushing equipment that is mounted on wheels or tracks and can be moved freely on the job site. The device is designed to crush large rocks, stones, and ores into smaller particles.

FTM Machinery's mobile crushing station combines feeding, crushing, screening, and conveying into one system, widely used in mining, aggregates, and waste treatment for crushing, shaping, and sand processing.

Advantages of mobile crushing plant

As a group of large crushing stations, mobile crushing is equivalent to a crushing production line. Choosing a mobile crushing plant over a stationary rock crusher plant comes with several significant benefits:

1. Portability and flexibility

Mobile rock crushers are easy to install, dismantle, and transport. This mobility is especially valuable when materials need to be processed at multiple or remote locations. Job sites with changing requirements benefit greatly from this flexibility.

2. Modular design

Modern mobile stone crushers are built with modular systems. A single chassis can accommodate different types of crushers, such as jaw, cone, and impact crushers. This allows for easy upgrades or changes in the processing setup depending on project demands.

3. Cost-efficiency

A mobile crusher for sale typically requires less infrastructure and installation time. It helps reduce transportation and labor costs by processing material at the source, eliminating the need to move raw materials to a central crushing facility.

4. Reduced environmental impact

By crushing materials on-site, mobile crusher plants minimize dust emissions and truck traffic, making them a more sustainable option. Their energy-efficient engines and dust suppression systems further enhance environmental friendliness.

When to use a mobile crushing equipment?

When you encounter the following situations, don't hesitate and use the mobile crushing equipment directly:

- Temporary crushing projects

- Short-term construction and mining operations

- Multiple job sites using similar materials at different times

- Urban areas where space and environmental regulations are strict

- Projects in remote locations where transporting raw materials is expensive or impractical

If your project involves seasonal or mobile work or operates on a tight timeline, investing in a mobile crushing plant may be the optimal choice.

Applications of mobile crushing equipment

A mobile rock crushing machine can be used to crush hard and medium-hard rocks, stones, minerals, construction waste, concrete, and other aggregates:

- Natural stone: Granite, basalt, marble, sandstone, limestone, bluestone, diabase, andesite, sandstone, etc.

- Minerals: Dolomite, iron ore, copper ore, coal, quartz, pebbles, molybdenum ore, limestone, coal, etc.

- Waste: Slag, coal gangue, tailings, etc.

- Recycled materials: Concrete, construction waste, bricks, glass, ceramics

These industries require a lot of mobile crushing plants:

- Mining: Crushing and processing of ores

- Construction: Producing aggregates for concrete and asphalt

- Recycling: Recycling demolition and construction waste (C&D waste)

- Quarrying: Crushing rock into crushed stone, gravel, or stone chips

- Infrastructure: Crushing materials for infrastructure projects such as highways, railways, roads, etc.

Types of mobile crushing equipment

There are several types of mobile crushing equipment. According to their walking method, the mobile crushing equipment is divided into the mobile crusher and portable crusher.

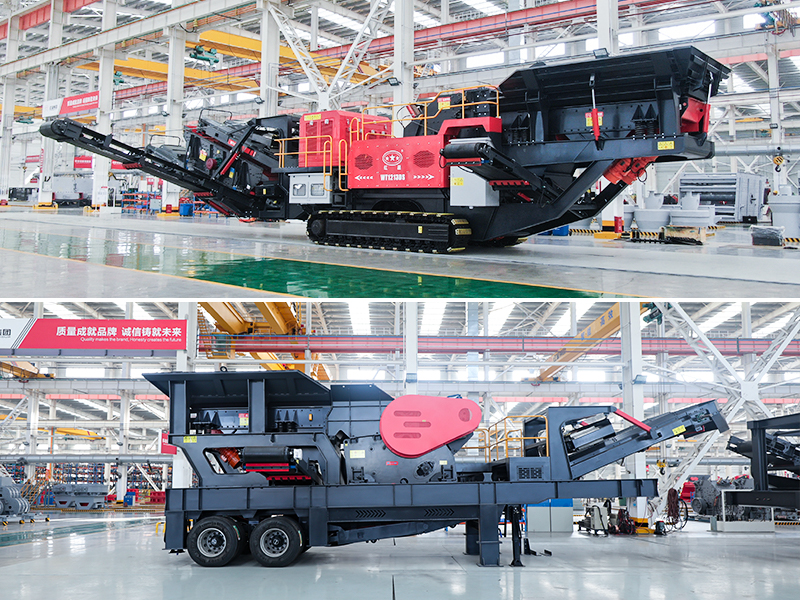

1. Mobile crusher

Mobile crusher, also called tracked crusher or crawler crusher. It moves by itself through hydraulically driven tracks, and can easily cope with terrains, slopes, and remote locations. They are often used in mining and rugged construction sites.

A mobile crushing station is a crushing line. It can be configured with mobile rock crushers and screens according to the crushing requirements.

- Types of crusher: Mobile jaw crusher, mobile cone crusher, mobile impact crusher, mobile sand crusher (sand maker)

- Feed size: 185–700 mm

- Capacity: 60–500 tons per hour

- Weight: 32–60 t

- Power system: Full hydraulic, D-type hybrid, E-type external power supply, etc. Customers can choose according to actual conditions such as fuel cost and operating cost.

- Adopt the advanced hydraulic power system and dust and noise reduction technology, environmental protection and energy saving.

- The installation cycle is short and can be installed in 4 to 6 hours.

- Easy to operate and maintain—requires only 1–2 workers with one-click start or stop for fast movement and crushing.

2. Portable crusher

A portable crusher, also called a wheeled crusher or tire type crusher, is semi-mobile and typically towed by trucks. This rock crusher is ideal for urban construction, roadwork, and building demolition.

Specifications:

- Types of crusher: Portable jaw crusher, portable cone crusher, portable impact crusher, and portable hammer crusher

- Feed size: 300–800 mm

- Capacity: 50–300 tons per hour

- Weight: 31–65 t

- Power: Uses mains electricity or diesel generator, can operate smoothly even when there is a power outage or no electricity in the suburbs.

- Equipped with a vehicle-mounted belt drive and independent control system, it requires no disassembly for transport and is ready for quick setup on site.

- No foundation needed—outrigger track plate unit can quickly setup on-site and folds for easy transport, reducing base investment. The entire installation takes 2 to 3 days.

- Easy to operate and repair, with escalators and wide pedals for easy inspection and maintenance.

How do you select the crusher type? Tracked mobile crusher vs. Wheeled portable crusher

| Feature | Crawler Type | Wheel Type |

| Mobility | Self-propelled via hydraulic tracks, suitable for rough terrains | Towed by semi-trailer, ideal for flat surfaces |

| Crushing Environment | Mining, mountains, wetlands, rugged areas | Construction waste, urban projects, road projects |

| Feed Size | 185–700 mm | 300–800 mm, larger feeding port |

| Crushing Efficiency | 60–500 tons/hour, higher than wheel type | 50–300 tons/hour |

| Power System | Multiple low-energy systems: fully hydraulic, diesel electric hybrid, and external power | Runs on mains electricity or diesel—ideal for suburban outages or no-electricity use |

| Installation Time | Quick 4–6 hour setup; easy relocation via hydraulic drive | No foundation needed; outrigger track plate allows 2–3 days rapid setup |

How to configure a mobile crushing plant?

A mobile crushing plant is highly customizable. Six factors should be considered:

- Material type (hardness, moisture content, input/output size)

- Production capacity

- Crushing stages (primary, secondary, tertiary crushing)

- Energy consumption

- Site size and budget

- Discharge fineness (fine aggregate, coarse aggregate)

The capacity of a mobile crusher plant ranges from 50 to 500 tons per hour, depending on the rock crusher you configure. A small crushing plant is usually equipped with one mine crushing station, while a large crushing plant requires multiple.

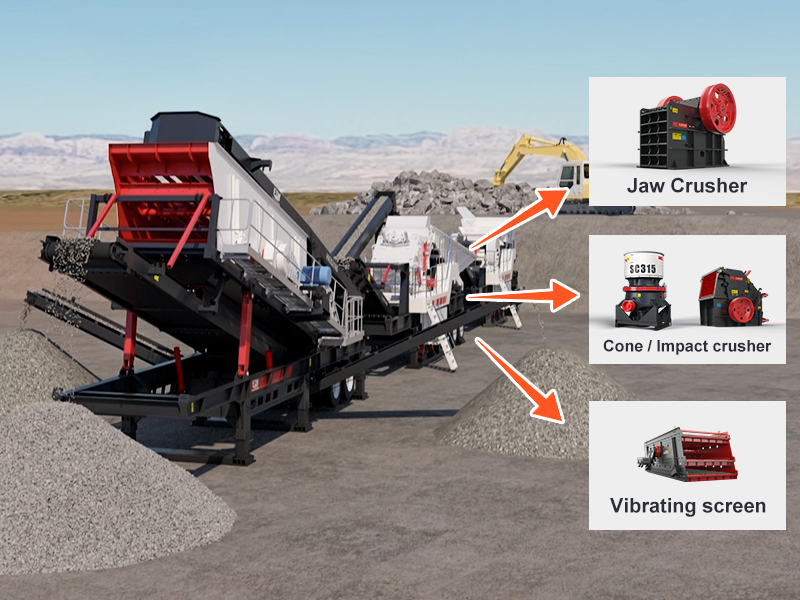

The stone crusher machines are configured according to the crushing stages of primary crushing, secondary crushing, and tertiary crushing.

- Jaw crusher: Used as a primary crusher for coarse crushing, breaking large bulk materials into smaller sizes.

- Cone crusher: Used as a secondary or tertiary crusher for fine size reduction, or as the first stage of the crushing process if the crushed material is small enough.

- Impact crusher: Suitable for various crushing applications, including secondary and tertiary crushing.

- Sand making machine: Used in the final crushing stage for high demand of fine materials (0–4 mm). By making sand and fine shaping, it produces high-quality M sand (artificial sand) with excellent cubic particle products and output of 50–380 tons/hour.

All stone crushers produce mixed materials that must be sorted by size. FTM Machinery mobile screens use up to 4 vibrating layers to accurately classify materials, minimizing blockages and efficiently separating fine and coarse aggregates.

- Fine aggregate: Particle size is no larger than 4.75 mm, used in the production of concrete, mortar, etc.

- Coarse aggregate: Particle size is larger than 4.75 mm, used in the construction of infrastructure such as roads and bridges.

The following are the mobile crushing configurations commonly used by our users:

- Mobile/Portable jaw crusher + cone crusher+ Vibrating screen: For hard rocks crushing and screening like granite, basalt, diabase, and iron ore.

- Mobile/Portable jaw crusher + impact crusher+ Vibrating screen: For softer rocks and stones like limestone, gypsum, dolomite, and calcium carbonate. After crushing and screening, you can obtain a good particle shape.

- Mobile/Portable hammer crusher + sand making machine+ Vibrating screen: For brittle materials requiring high-quality manufactured sand. The final product has become the best aggregate with the finest particle size.

How does a mobile crushing plant work?

A typical mobile crushing plant works through these steps:

- 1Feeding: The large bulk material is loaded into the vibrating feeder.

- 2Primary crushing: The mobile jaw crusher crushes the large chunks.

- 3Secondary crushing: The crushed material is passed to an impact crusher or cone crusher for medium crushing and fine crushing.

- 4Screening: The vibrating screen sorts materials by size, sending qualified ones to the conveyor and returning the unqualified materials for further crushing, forming a closed-loop system.

- 5Output: The qualified finished aggregate is discharged from the belt conveyor.

The mobile crushing plant combines feeding, crushing, screening, and conveying into a single crushing workflow, minimizing downtime and maximizing productivity through a continuous crushing process.