Limestone has a Mohs hardness scale of 3–4. With the moderate hardness, stable composition, low cost, and eco-friendliness, it is an ideal material for sand production. This blog will introduce equipment suitable for making limestone sand.

The limestone sand-making process

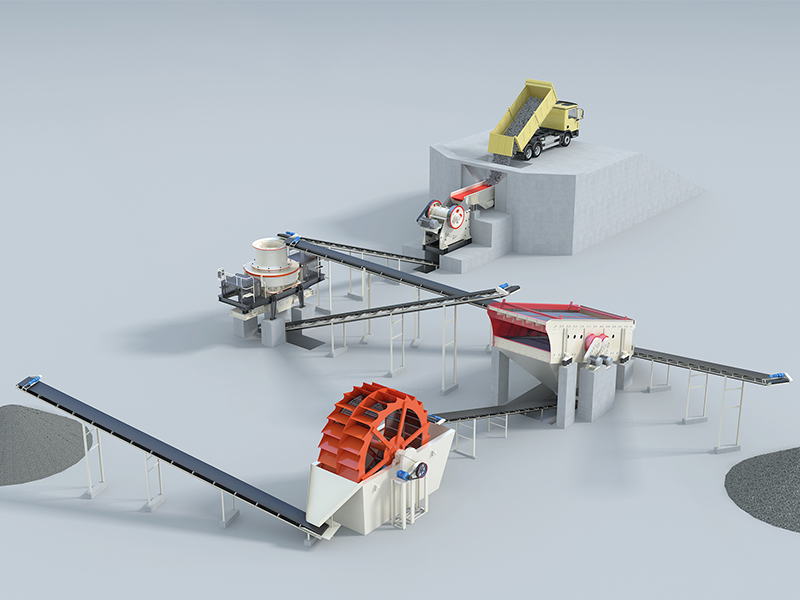

The limestone sand production line can be described as: feeding–crushing–sand making–screening–sand washing.

In the limestone sand production line, the initial process of limestone and fine sand making are all related to the quality of limestone sand products. We can provide you with the appropriate crushing, sand making and screening equipment.

1. Limestone crushing machine

After extraction, the limestone requires crushing process. Through primary and fine crushing, the limestone is reduced to a particle size suitable for sand production. The following crushing machines are available for you:

Jaw crusher is the ideal choice for coarse crushing of limestone. Its jaw plate includes a fixed plate made of high-manganese steel or durable materials, and a movable plate with a casting structure. They can offer better wear resistance and a longer service life.

Europen type jaw crusher adopts the advanced technology, perfectly combining optimized crushing cavity and working parameters.

This machine has a maximum feed size of 900 mm, a discharge range of 45–225 mm and high production capacity of 50–750 t/h. So it's particularly suitable for the initial processing of large limestone.

With a maximum output particle size of around 200 mm, coarse crushing limestone can't be fed directly into the sand making machine. It requires additional equipment for secondary and fine crushing.

The impact crusher is suitable for secondary crushing of low and medium hardness limestone, combining both crushing and initial shaping.

- 1 Its adjustable gap between the impact plate and plate hammer can effectively control the output particle size of limestone sand with a cubic shape.

- 2 Each blow bar is made of high-chromium cast iron with excellent material. It designed by our FTM Machinery weighs 230 kg. And it's heavier than similar products of other companies with higher crushing efficiency.

- 3 Its maximum feed size is 250–350 mm, with a processing capacity of 60–600 t/h and high crushing efficiency.

If you want to buy the machines, Contact us

2. Limestone sand making machine

Sand making is the core process, transforming crushed limestone into sand particles and producing well-shaped limestone sand.

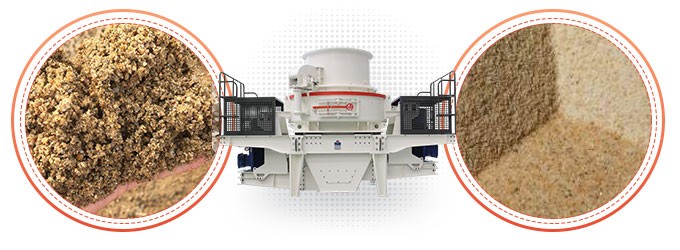

The impact sand making machine is ideal for providing high-quality sand and gravel aggregates. Its deep-cavity rotor design allows for higher limestone pass and processing capacity.

The sand maker is available in "rock-on-rock" and "rock-on-iron" structure. FTM Machinery provides VSI and HVI sand maker.

VSI sand making machine is a common but highly efficient sand making equipment.

- 1 Maximum feed size: hard materials <45 mm, soft materials <50 mm.

- 2 50% energy savings and 20% higher sand production rate than traditional sand making machine. 10% higher output than HVI sand making machine.

- 3 Moderate price and high cost-effectiveness.

HVI sand making machine adopts advanced technology and is eady to maintain, use.

- 1 Maximum feed size: hard materials <50 mm, soft materials <55 mm.

- 2 Two remarkable functions of sand making and shaping with a beautiful size and better grain shape.

- 3 Equipped with intelligent control system to ensure efficient operation.

Besides, the machine is also equipped with a dust control device to reduce pollution. So it can improve the purity of the crushed limestone sand, and ensure environmental friendliness.

If you want to buy the machines, Contact us

3. Limestone screening machine

The vibrating screen has a simple structure. The limestone sand vibrates evenly across the screen surface. The limestone sand that meets the needs will be screened for the next stage while the unsuitable sand is re-entered into the sand maker for further processing.

The strong vibration of the sieve box effectively reduces limestone sand blocking, thereby achieving high production efficiency.

According to your needs, the vibrating screen can be equipped with multiple screen decks, up to four. The sizes can be 4–50 mm, 5–80 mm, or 5–100 mm.

Its maximum feed size is 200 mm. The processing capacity ranges from 12–90 m³/h, with a maximum capacity of 1,300 t/h. So it can efficiently produce limestone sand of different particle sizes.

If you want to buy the machines, Contact us

The use of making sand from limestone

Limestone is a common material for manufactured sand. Making limestone sand is to process mined limestone ore into high-quality sand through crushing, sand making, screening and other processes.

Limestone sand of different particle sizes is widely used in various fields such as construction, industry, and agriculture:

- Powder (particle size <0.1 mm): Used as cement raw materials, desulfurizer, agricultural lime and so on. Also used as a filler in products such as toothpaste and cosmetics.

- Fine sand (particle size 0.1 mm–0.5 mm): Used in the production of slurry and some concrete and as a raw material in papermaking, plastics, and other industries.

- Medium sand (particle size 0.5 mm–2 mm): Used in the production of asphalt concrete and bricks, and for water treatment, soil improvement.

- Coarse sand (particle size 2 mm–5 mm): Used as a raw material for making cement, in road substrate, railway ballast.

Two customer cases of limestone sand making line

1. Australia limestone sand production line

The company provided limestone materials and purchased some equipment to produce high-quality limestone sand for concrete and cement.

| Capacity | 300 TPH |

| Feeding size | ≤900 mm |

| Discharging size | 0–5 mm, 5–10 mm, 10–20 mm |

| Equipments in the limestone sand production line |

1. GZD1100×3600 vibrating feeder 2. HD98 jaw crusher 3. PF–1210 impact crusher 4. VSI–1140 sand washing machine 5. 3YK2160 vibrating screen |

Customer comment:

"After understanding our needs, FTM Machinery's engineer introduced a cost-effective limestone sand making line. The low-cost, high-return system has given substantial profits. All equipment can be monitored at any time to ensure continuous production."

2. Colombia limestone sand production line

The factory provided sand-soil mixture and required limestone sand for construction. Our limestone sand production line's equipment produced finished products with suitable particle size.

| Capacity | 200–300 TPH |

| Feeding size | ≤800 mm |

| Discharging size | 0–5 mm, 10–20 mm |

| Equipments in the limestone sand production line |

1. GZD1100×3600 vibrating feeder 2. HD110(912) jaw crusher 3. PF–1214 impact crusher 4. VSI–9526 sand making machine 5. LX915–15–65 spiral sand washing machine |

Customer comment:

"Equipments in the sand production line meet requirements of our production plant. It produces high-quality particles and has high efficiency. It also adheres strictly to environmental production standards, resulting in low energy consumption."

Conclusion

Limestone sand production serves as a premium alternative to natural sand, offering irreplaceable value in solving sand resource shortages.

Based on various sand quality requirements according to different applications, FTM Machinery will provide you with suitable sand making equipment and produce high-quality limestone sand.