What is a river sand dryer?

The river sand dryer is a three-pass rotary dryer, also known as a rotary sand dryer, designed for reducing moisture in various types of sand or aggregates.

- Natural sand: river sand, sea sand, yellow sand, and washed sand, etc.

- Processed sand: machine-made sand, construction sand, and crushed stone, etc.

- Industrial sand: quartz sand, silica sand, glass sand, dolomite, pebble sand, basalt sand, etc.

The dryer can reach drying temperatures of up to 750℃, typically drying materials such as chunks, particles, or powders with a size of 30 mm or less.

The typical particle sizes and drying temperatures for common sand types are as follows:

| Material | Particle size | Drying temperature |

| River sand | 4–20 mm | 80–180°C |

| Quartz sand | 0.6–4 mm | 60–80°C |

| Yellow sand | 0.1–3 mm | 150–200°C |

| Silica sand | 0.1–2 mm | 150–180°C |

| Glass sand | 0.1–3 mm | 160–200°C |

| Aggregate | 4–30 mm | 250–750°C |

Applications of river sand dryer

The river sand dryer is widely used in industries such as construction, chemicals, casting, and metallurgy, helping customers improve production efficiency and reduce costs across various fields.

Key applications include:

- Construction: Dried sand is used to produce dry mortar, concrete, bricks, and other building materials.

- Chemical industry: Used to dry chemical raw materials or produce various chemicals.

- Casting industry: Dries casting sand to ensure smooth casting processes.

- Metallurgy: Dries metal ores to aid in subsequent smelting and processing.

- Environmental protection: In construction waste recycling, dries sand and aggregates from waste for reuse.

- Other industries: Used in cement, glass, and other sectors to dry various sands and raw materials, improving resource utilization.

The sand drying machine offers high-capacity sand drying, with the ability to dry up to 70 tons of material per hour. For users with lower production requirements, smaller dryers are also available, capable of drying up to 20 tons per hour.

Below are the specifications of common sand dryers to help you better match your production needs:

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Cylinder volume( m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Initial moisture of slag(%) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag(%) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground(%) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (%) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature(℃) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity(T/h) |

Yellow sand: 25-30 Slag: 20-25 |

Yellow sand: 30-35 Slag: 25-30 |

Yellow sand: 35-40 Slag: 30-35 |

Yellow sand: 45-50 Slag: 35-40 |

Yellow sand: 65-70 Slag: 60-65 |

| Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

Why choose FTM Machinery river sand dryers?

FTM Machinery is a leading sand dryer manufacturer with a professional R&D team and advanced drying processes. We provide cost-effective, customized drying solutions, making us the top choice in countries like the USA, Russia, and the Philippines.

- Efficient drying: The adjustable frequency motor, 750°C air inlet temperature, and efficient sealing design ensure even heating, minimize heat loss, and reduce sand moisture to 0%.

- High thermal efficiency: The three-layer concentric drum design extends heat exchange time, improving heat circulation for the sand in the dryer and reducing energy consumption by 30%–50%.

- Strong wear resistance: Key wear parts like the drum and lifting plates are made from wear-resisting manganese plates, lasting 3-4 times longer than regular steel.

- Stable performance: The sand dryers have a unique structure that prevents material buildup, no parts that wear easily, and can run continuously for 24 hours.

- Customizable: Various models for both small and large capacities are available, with customization options. Our dryers offer higher drying capacity compared to industry peers.

- Space-saving: The drum length is only one-third of a single-pass dryer, saving up to 65% in floor space and reducing investment costs.

- Multiple fuel options: Supports coal, oil, gas, etc. Low fuel consumption, no air leakage, complete combustion, and drying costs are only one-third of similar products.

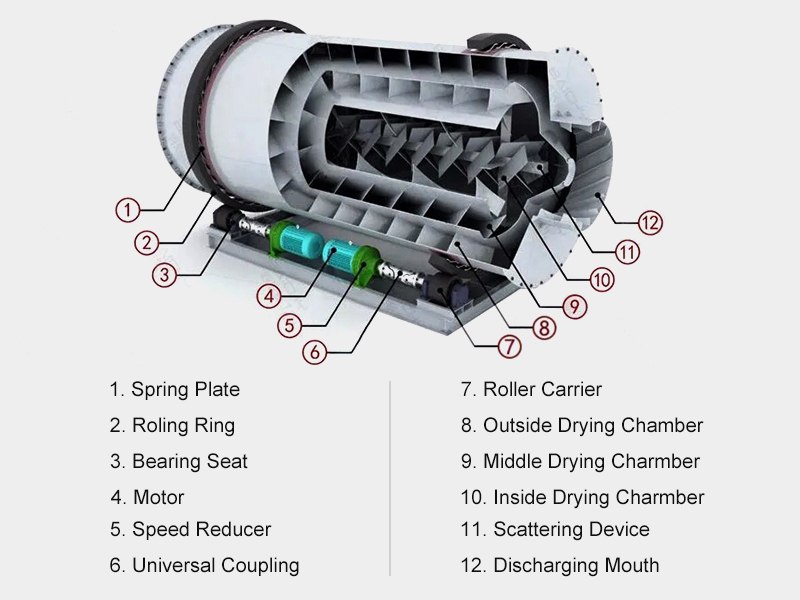

Main components of the sand river dryers

The river sand drying equipment features a rotary drum horizontal loading design, offering a more compact structure with the same output and reduced floor space.

It mainly consists of four parts: drum body, support system, transmission system, and thermal system.

1. Drum body

The three-layer drum structure, with inner and middle drums surrounded by an outer drum, forms a self-insulating system. Heat from the inner and middle drums enhances heat exchange, while the outer drum's position reduces heat loss and surface dissipation.

2. Support system

The support system consists of rollers, catch wheels, and riding wheels. The rollers rotate with the barrel, the riding wheels support it, and the catch wheels prevent displacement.

3. Transmission system

The transmission system includes big gear, pinions, motor, and gear reducer. The drum body is driven by the motor through a triangular belt, gear reducer, pinions, and big gear.

4. Thermal system

The thermal system is mainly divided into two types: thermal cotton and galvanized thermal plate. The thermal cotton is made of basalt, dolomite, and binder by high-temperature melting.

How does a river sand dryer work?

The sand dryer is the core equipment in the drying line. It dries sand by heating wet sand with hot air or other heat sources, evaporating moisture to reduce moisture content.

Sand drying process:

- 1 Material feeding: Wet sand enters the inner drum (the innermost drum) through the feeder and conveyor belt, and is processed in a rectangular multi-loop manner.

- 2 Inner drum drying: Hot air is introduced into the inner drum, where the sand absorbs heat and evaporates moisture at the highest temperature zone.

- 3 Middle drum drying: The sand moves into the middle drum, continuing to lose moisture as it absorbs heat.

- 4 Outer drum drying: In the outer drum, the sand is further dried at a lower temperature.

- 5 Finished product output: The dried sand is discharged from the outlet and can be directly stored or sent for further processing.

FTM Machinery offers a complete drying production line, including belt conveyors, a metering feeder, a lifting system, and a dust collector. GET A FREE QUOTE!

FTM Machinery customer case in Indonesia

A customer from Indonesia contacted FTM Machinery to purchase a river sand dryer. After several discussions, our engineers recommended the right equipment and provided technical guidance based on the customer's material and drying needs.

Customer requirements and equipment specifications

| Material | River sand |

| Initial moisture | 8–10% |

| Final moisture | 1% |

| Capacity | 70 t/h |

| Max temperature | 750°C |

| Auxiliary equipment | Feeder, feed conveyor, discharge conveyor, induced draft fan, hot air furnace, cyclone separator |

Customer feedback:

"FTM Machinery's river sand dryer significantly improved production efficiency. The equipment has high thermal efficiency, low heat loss, and the entire drying process is automated, saving substantial labor costs."

Frequently asked questions about river sand crushers

1. What affects river sand dryer efficiency?

- a. Heat source: Different heat sources affect furnace temperatures, influencing airflow in the dryer and drying time, which impacts equipment output.

- b. Cylinder rotation speed: Faster cylinder rotation reduces drying time by accelerating material movement.

- c. Material moisture: Moisture content impacts drying rate; fluid materials aren't suitable for drying equipment. A filter press can remove excess water before the dryer, boosting efficiency.

- d. Material evaporation intensity: Higher evaporation intensities speed up drying and improve dryer efficiency.

2. How to control rotary sand dryer temperature in winter?

- a. Add fuel gradually based on temperature readings to prevent fluctuations and save energy.

- b. Use appropriate fuel and temperature for the material, opting for high-calorific fuels when needed.

- c. Insulate the dryer in cold weather to maintain stable temperatures and reduce re-drying.

- d. Install a temperature control device to monitor and adjust fuel and ventilation.

3. How to maintain a river sand dryer?

- Regularly clean key areas like the feed and discharge ports and drum interior to prevent dust blockage and ensure smooth airflow in the sand drying process. Check and lubricate gears and bearings to prevent wear, inspect the combustion system for proper fuel supply and uniform heat flow, and replace worn parts like the drum, bearings, and seals to maintain the efficiency of drying sand.