Sand is one of the most essential materials in construction. However, not all sand is the same. Different construction applications require different types of sand with specific particle sizes, shapes, and cleanliness levels.

In this guide, we'll explore the main types of sand used in construction, explain their characteristics, and clarify where each type is commonly used. This article is intended as a practical reference for contractors, engineers, students, and anyone seeking a clear understanding of construction sand.

What is construction sand?

Construction sand refers to natural or manufactured granular material used in concrete, mortar, plastering, filling, and road construction. It is typically classified based on:

- Particle size

- Shape and texture

- Source (natural or manufactured)

- Intended application

Choosing the right sand type is essential for ensuring strength, durability, and workability in construction projects.

Different types of sand used in construction

| Sand type | Main use | Particle size | Source |

| River sand | Concrete, plastering | Fine–medium | Natural |

| Manufactured sand | Structural concrete | Controlled | Manufactured |

| Concrete sand | Foundations, slabs | Medium–coarse | Natural / manufactured |

| Coarse sand | Structural works | Coarse | Natural |

| Masonry sand | Brickwork, plastering | Fine | Processed |

| Fill sand | Backfilling | Mixed | Natural |

| Crushed stone sand | Road base | Fine | Manufactured |

1. River sand

River sand is a naturally occurring sand collected from riverbeds and riverbanks. Over time, water erosion smooths the sand particles, giving them a rounded shape.

Key characteristics:

- Smooth and rounded particles

- Low clay and impurity content (in most cases)

- Good workability in concrete and mortar

Due to its natural origin, river sand is a preferred material for high-quality concrete production, masonry, and plastering. However, environmental regulations and over-extraction have limited its availability in many regions.

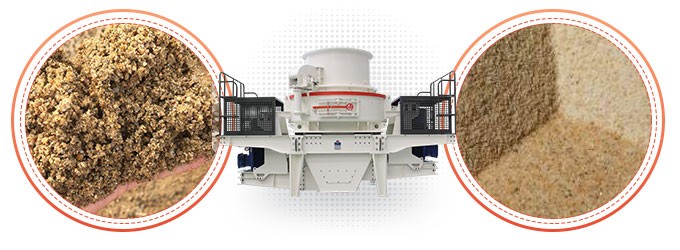

2. Manufactured sand (M sand)

Manufactured sand (M sand) is an artificial alternative to river sand. It is produced by crushing hard rocks such as granite, basalt, limestone, or quartz into fine aggregates.

Key characteristics:

- Angular and cubical particle shape

- Controlled particle size distribution

- Consistent quality

Unlike river sand, manufactured sand allows full control over particle size and gradation. This makes it an ideal choice for high-rise buildings and large infrastructure projects such as bridges and dams.

M sand offers better consistency than natural sand and can be engineered to meet specific construction standards, making it widely used in modern construction.

3. Concrete sand

Concrete sand is a type of coarse sand with relatively large particles and a rough texture. It is specially graded to enhance the bonding strength of concrete mixtures. Concrete sand is commonly used in concrete foundations, slabs, and columns, as well as other structural concrete components.

Key characteristics:

- Coarser texture than plastering sand

- Enhances concrete strength

- Good drainage properties

Concrete sand is often washed and screened to remove clay, silt, and organic impurities that could weaken concrete.

4. Coarse sand (Pit sand)

Coarse sand, also known as pit sand or p sand, is obtained from deep pits or inland deposits rather than rivers. Due to the presence of iron oxides, it often has a reddish or orange color.

Key characteristics:

- Sharp, angular particles

- Larger grain size

- High strength contribution

Its angular shape improves mechanical interlocking, making it suitable where strength is more important than surface smoothness.

5. Masonry sand

Masonry sand is a clean, fine-grained sand specifically processed for bricklaying and block construction. Unlike coarse concrete sand, masonry sand must have a smooth, fine texture to allow mortar to spread easily between brick joints.

Key characteristics:

- Fine particle size

- Clean and well-graded

- Improves workability of mortar

This type of sand is widely used in brickwork, blockwork, and plastering applications where appearance and smooth finishes are required.

6. Fill sand (Filling sand)

Fill sand is a low-cost sand that is typically unwashed or lightly processed. It is not intended for structural concrete or decorative finishes. It is commonly used for site leveling, trench backfilling, and filling large voids.

Key characteristics:

- Mixed particle sizes

- May contain small stones or soil

- Economical

Fill sand provides stable compaction and drainage but is not suitable for load-bearing concrete applications.

7. Crushed stone sand

This type of sand is typically a fine crushing byproduct from large aggregate crushing plants. In the past, it was often considered waste, but with modern processing technologies, it has gained significant economic value.

By processing these fines through shaping and washing systems, crushed stone sand can be used for road base layers or low-strength construction applications.

Fine sand vs coarse sand: Which sand is best for construction?

| Aspect | Fine sand | Coarse sand |

| Particle size | Smaller | Larger |

| Surface texture | Smooth | Angular |

| Main use | Plastering, masonry | Concrete, foundations |

| Strength contribution | Lower | Higher |

The best sand depends on the application:

- Structural concrete: Concrete sand or M sand

- Plastering: River sand or masonry sand

- Brickwork: Masonry sand

- Backfilling: Fill sand

- Road base: Crushed stone sand

Using the correct sand type improves durability, reduces material waste, and ensures compliance with construction standards.

Conclusion

Understanding the different types of sand used in construction is essential for achieving safe, durable, and cost-effective building projects. Each sand type has unique properties that make it suitable for specific applications—from high-strength concrete to simple site backfilling.

By selecting sand based on particle size, shape, cleanliness, and intended use, builders and engineers can ensure better performance and long-term reliability in construction projects.