Contact Our EngineerGet the Latest Quote

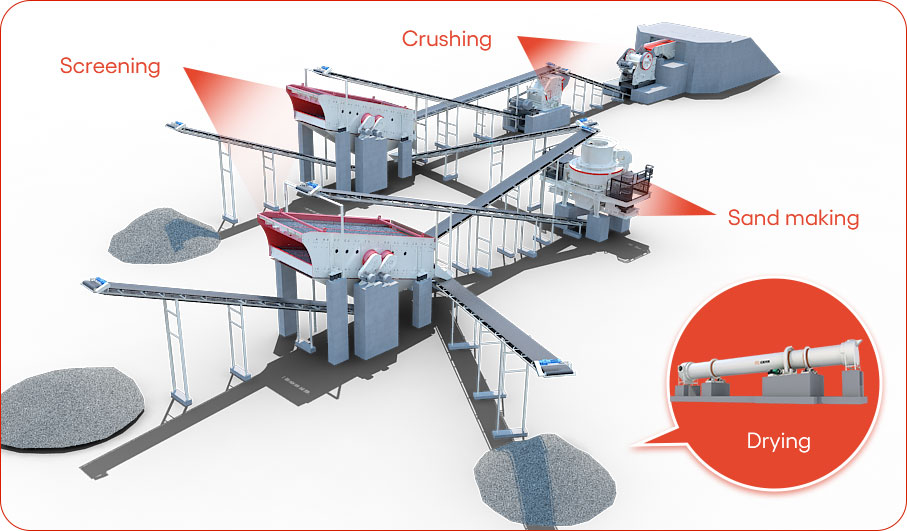

Ftmmachinery has thousands of sand making lines around the world. These production lines are based on our field-proven equipment for over 40 years. Read this blog to learn about M Sand and its production process, which will benefit your investment in this field.

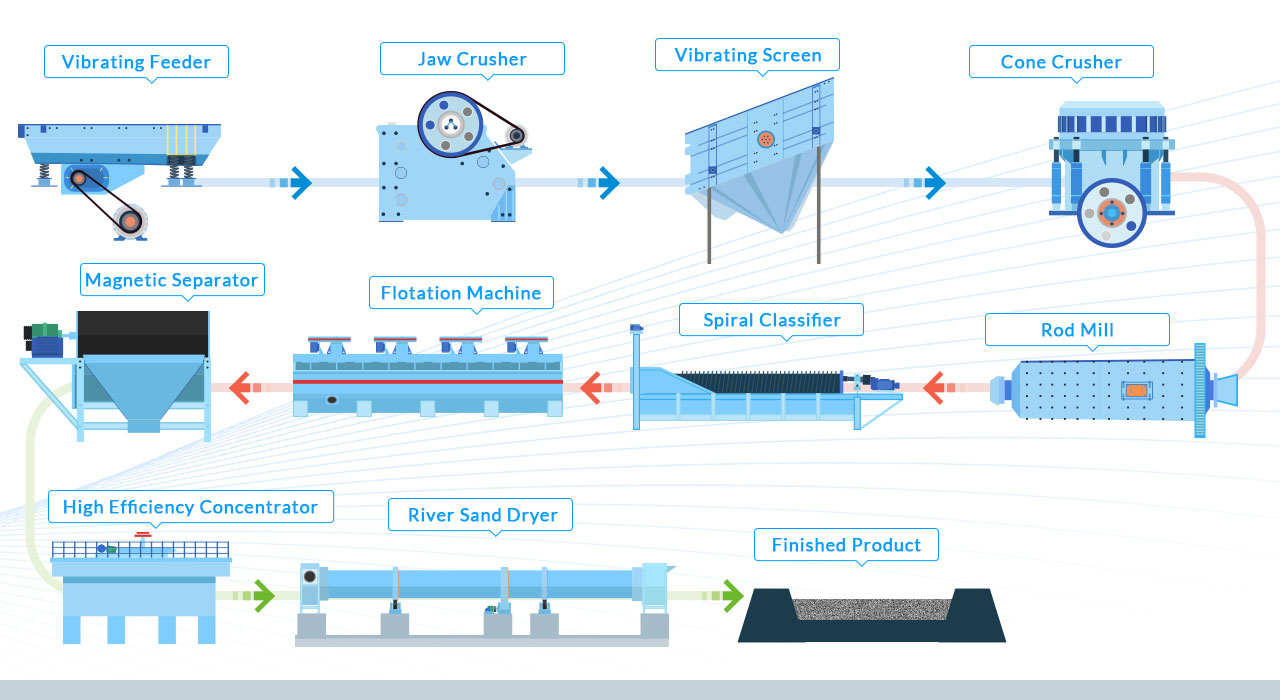

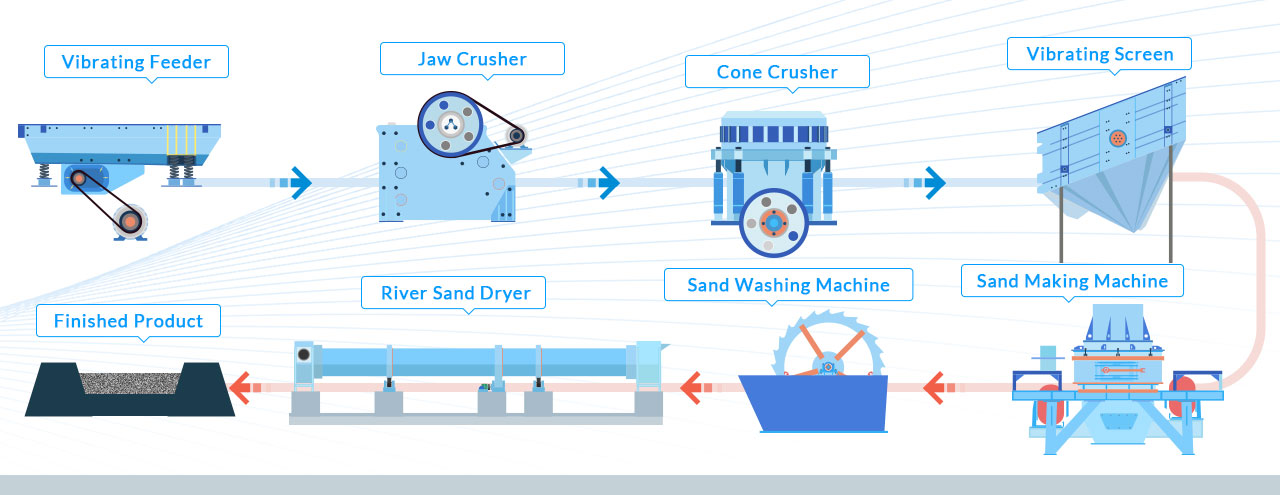

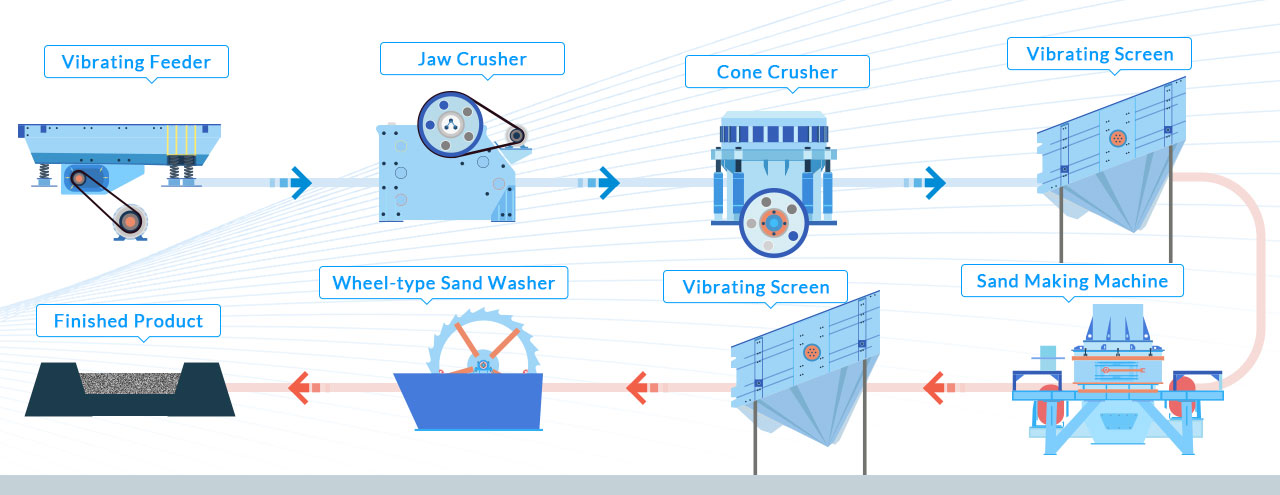

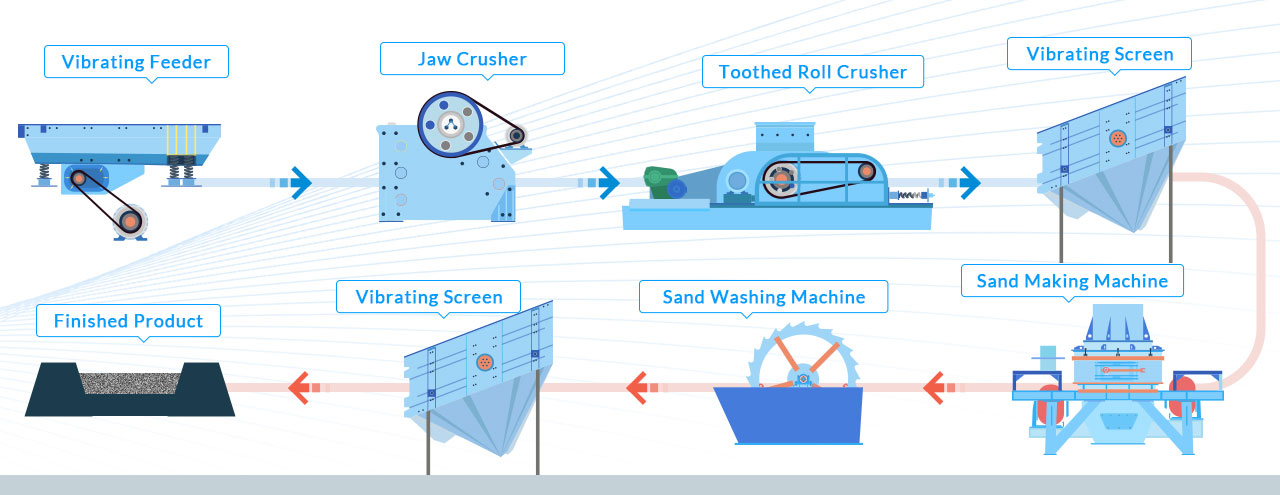

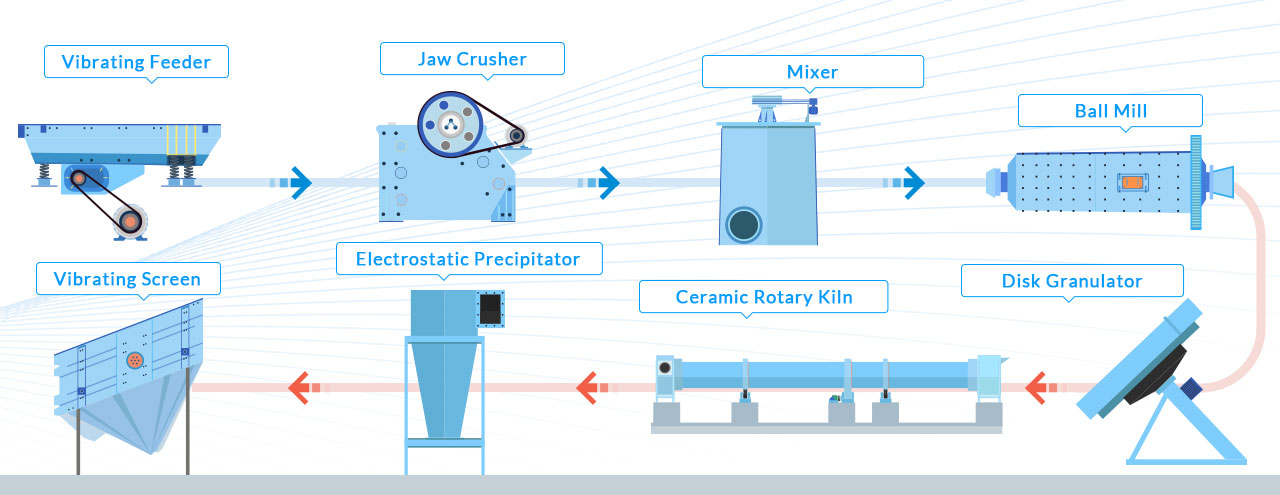

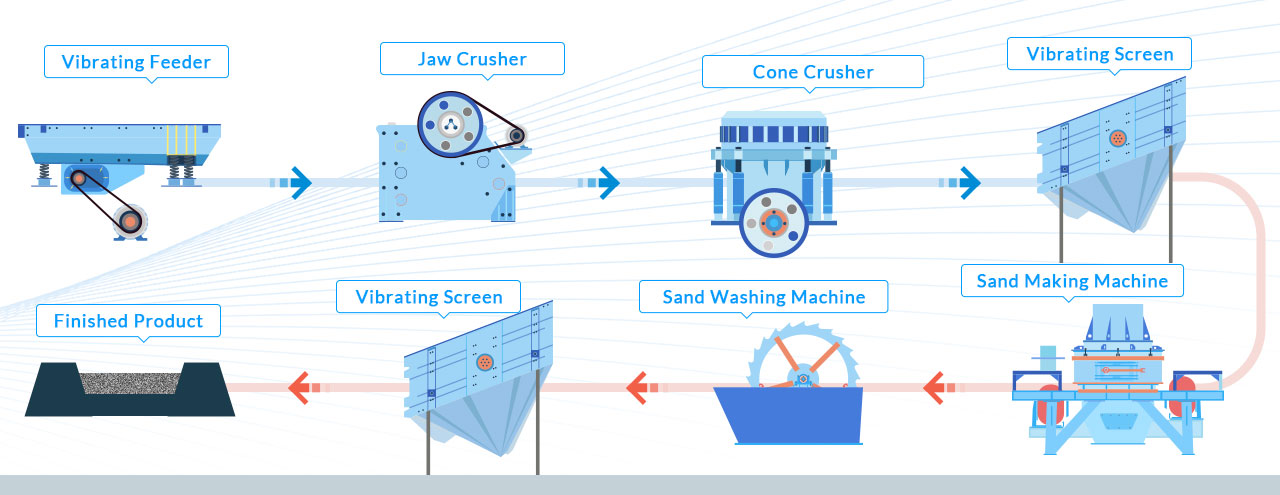

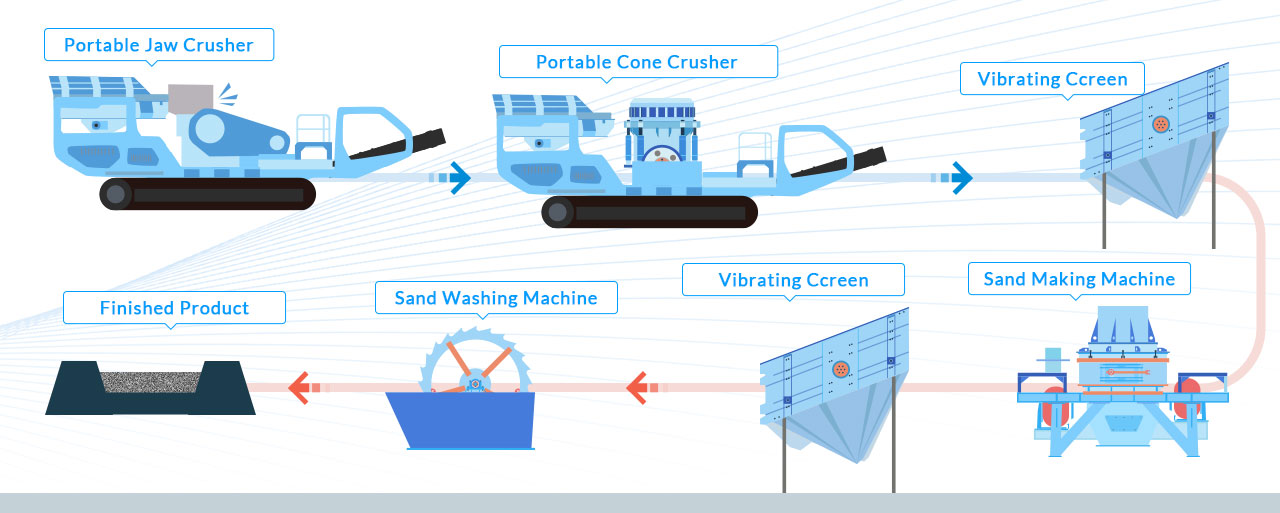

Jaw Crusher

Jaw Crusher

Cone Crusher

Cone Crusher

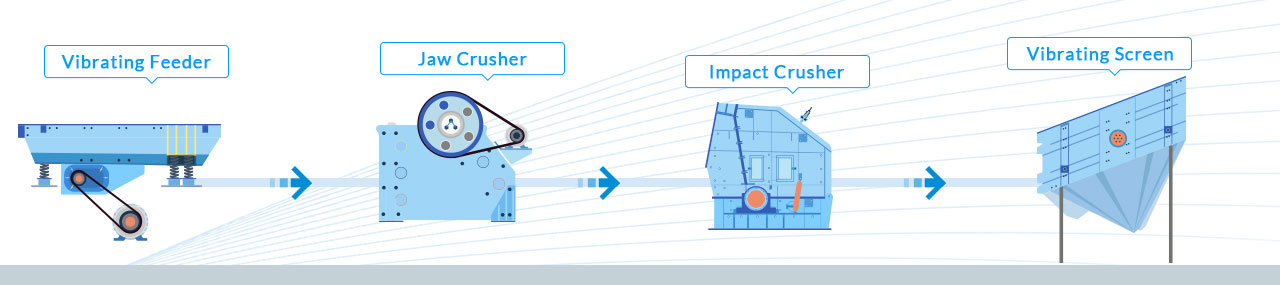

Impact Crusher

Impact Crusher

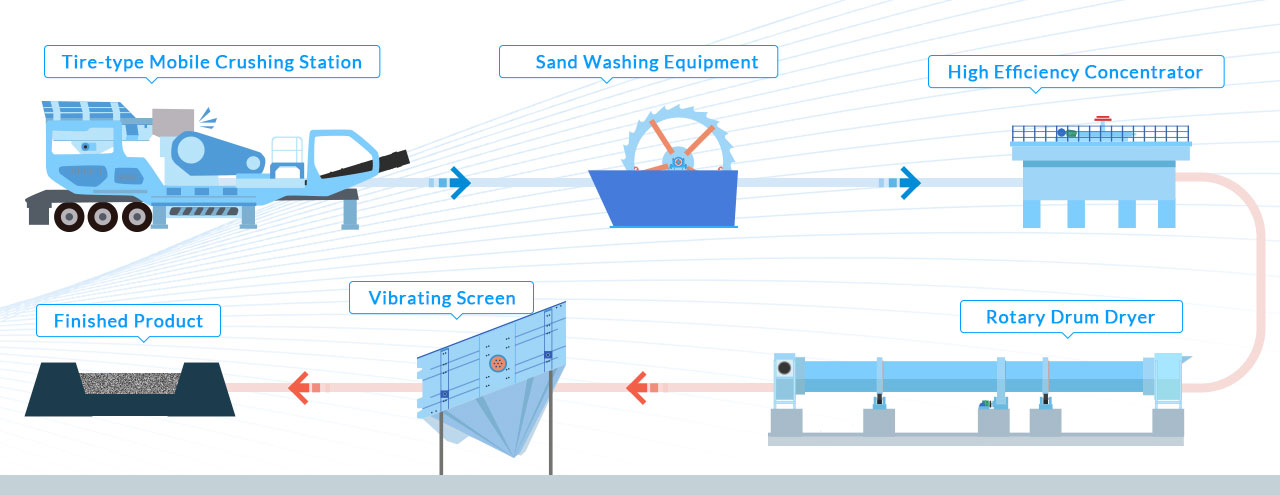

Vibrating Screen

Vibrating Screen

Sand Making Machine

Sand Making Machine

Sand Washing Machine

Sand Washing Machine

Sand Dryer

Sand Dryer