Manufactured sand (also called artificial sand) is produced from rocks, minerals, tailings, or industrial waste through crushing, screening, and sand making processes. The resulting particles are smaller than 4.75 mm.

Among them, particles smaller than 75μm are stone powder, which mainly consists of calcium carbonate. In the m sand manufacturing process, the generation of stone powder is inevitable.

Stone powder affects the manufactured sand

An appropriate amount of stone powder helps enhance the strength of concrete or cement and reduce the risk of segregation and bleeding during the hydration process.

However, an excessive amount of stone powder can compromise the quality of the manufactured sand, weaken the bonding between the sand aggregate and cement, and reduce the durability of the concrete.

There are clear market standards for the stone powder content in manufactured sand:

- Grade I sand: ≤1.0%

- Grade II sand: ≤3.0%

- Grade III sand: ≤5.0%

In the concrete industry—for example, C50 concrete—the recommended stone powder content is between 5% and 10% to balance strength and workability.

How to control stone powder content in manufactured sand?

So, how can the stone powder content in manufactured sand be effectively controlled to meet the quality requirements of concrete and construction projects? FTM Machinery engineers have summarized four solutions and the corresponding treatment equipment.

Select high-quality raw materials

The parent rock determines the quality of manufactured sand. When selecting raw materials, thorough exploration is essential. Choose mines with thin soil layers, minimal interlayer mud, high rock strength, and good integrity to minimize the generation of stone powder.

The parent rock should not have potential alkali-aggregate reaction activity and should be clean, hard, and free of weathered fossils. The following are common types:

- Granite and sandstone: With their high quartz content, they are widely used in sand and gravel aggregate production lines, but the issue of stone dust needs to be addressed.

- Quartz sandstone: An excellent raw material for manufactured sand production, matching or even surpassing natural sand in both strength and particle size.

- River pebbles: A high-quality raw material for sand production, offering a good alternative to natural sand in terms of strength, particle size, and color.

- Basalt: When used in concrete, it can reduce weight without reducing strength. It also provides sound and heat insulation, making it ideal for lightweight concrete in high-rise buildings.

Choose the right sand making machine

Based on advanced German technology, FTM Machinery has independently developed three high-efficiency sand making machines:

1. VSI series sand making machine

Featuring a deep cavity rotor design, this machine offers higher throughput. Compared to traditional sand makers, it saves 50% energy and increases output by 10%.

Max. feed size: Hard materials <45 mm, Soft materials <50 mm

Capacity: 40–650 tons/hour

2. HVI series sand making machine

Integrates sand making and shaping functions. The optimized material impact angle ensures better grain shape, uniform size, and attractive appearance.

Max. feed size: Hard materials <50 mm, Soft materials <55 mm

Capacity: 50–585 tons/hour

Available in tire or track-mounted configurations. It easily moves to production sites for on-site processing of coarse, medium, and fine sand.

Highly mobile and easy to operate

Capacity: 5–380 tons/hour

Note: The feed size of raw materials for manufactured sand must meet equipment requirements. Oversized feed can affect sand quality, increase fine powder content, and in severe cases, damage the machine.

All three sand making machines offer automated control and adjustable discharge sizes, producing 0–20 mm cube-shaped sand with low flake content — ideal for construction, cement, and concrete.

Dry-type stone powder recovery

Dry stone powder recovery separates and collects stone powder using dry screening and powder collection. It uses little to no water, saving water resources and cutting the investment costs on drainage and wastewater treatment, with strong environmental benefits.

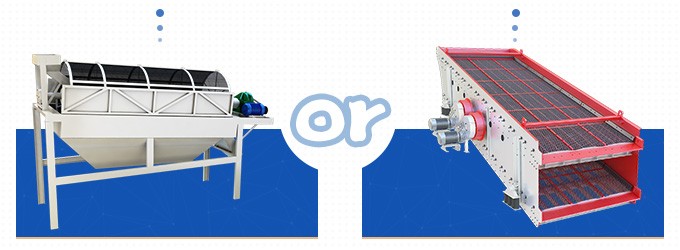

After sand crushing, manufactured sand and aggregates are screened by the vibrating screen to disperse clumped stone powder and optimize particle gradation. The common screens include the circular vibrating screen and linear vibrating screen.

The fineness modulus of manufactured sand should be 2.6–3.0. Use 3.0 or 3.5 mm screens to remove large particles, letting smaller ones pass to the finished sand silo via the belt conveyor. This reduces the loss of stone powder.

After screening, lost stone powder is recovered and evenly mixed into the finished sand. Using fluid mechanics principles, FTM Machinery Dust Collector adjusts air volume and pressure with a fan to precisely separate stone powder from sand, improving sand quality.

The final crushed sand contains less than 2% moisture, making them ready for use in concrete, dry-mix mortar, and other applications. Even in low-temperature winter, the sand aggregate does not freeze, ensuring continuous year-round production.

Wet type sand washing method

The wet type sand washing method uses the sand washer to remove stone powder from manufactured sand until the stone powder content meets the construction sand standard. The manufactured sand is clean with minimal impurities.

FTM Machinery recommends two types of sand washing equipment that efficiently remove waste materials such as soil and stone powder without generating dust or air pollution. The processing capacity can reach 350 tons per hour.

- Wheel-type sand washer: Simple structure, good cleaning performance, low water consumption, low failure rate, and minimal loss of fine sand and stone dust.

- Spiral sand washer: An upgraded version of the wheel-type sand washer. It offers better cleaning performance. Some sand making plants often use a combination of wheel-type and spiral sand washers for optimal sand and gravel quality.

If the washed sand is too wet, a rotary sand dryer can dry it. FTM Machinery uses drum drying process to removes moisture in sand. It can dry 76 tons of sand every hour and reduce the final moisture to 0.5%–1% or less.

The above four methods can help control the stone powder content in manufactured sand, thereby improving the grading of sand and solving the recycling and environmental protection problems of stone powder waste.