What is a lignite dryer?

A lignite dryer, also known as a lignite rotary dryer or coal dryer, is a highly efficient machine designed to dry materials like coal, lignite, coking coal, coal powder, raw coal, coal slime, fly ash, and carbon black. It is especially effective for drying lignite with high moisture content.

The coal dryer can reduce the moisture content of coal from 20%–70% to below 13%, increasing its calorific value and combustion efficiency. The equipment is widely used in power generation, metallurgy, and building materials industries.

Technical parameters of rotary dryer:

| Spec./m(Dia.×Length) | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Φ1.2×8.0 | 1.9–2.4 | 700–800 |

| Φ2.2×16 | 13.0–16.2 | 700–800 |

| Φ3.0×25 | 37.7–47.1 | 700–800 |

| Φ3.6×28 | 60.8–76.0 | 700–800 |

Technical parameters of indirect heat dryer:

| Spec./m(Dia.×Length) | Shell cubage(m³) | Highest Inlet Air Temperature(℃) |

| Φ1.5×15 | 20.27 | 850 |

| Φ1.8×23 | 39.33 | 850 |

| Φ2.2×25 | 69.15 | 850 |

Note: The above parameters are examples of specific models. For more models and customization options, please contact our expert team. We will provide you with detailed support and consultation. Inquire now!

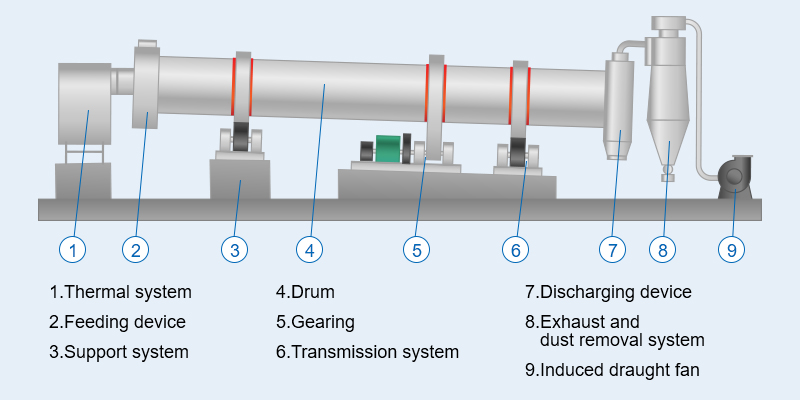

Main structures of the lignite dryer

The lignite coal dryer mainly consists of the drum, support system, transmission system, thermal system, feeding and discharging devices, and more.

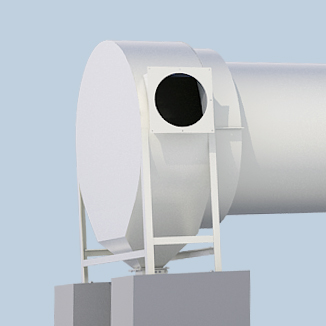

1. Drum

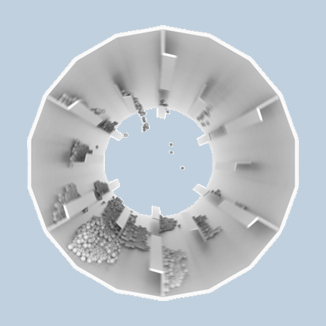

The drum is the main part of the dryer, made of strong steel. It has a spiral plate at the feed inlet, lifting blades inside, and baffles at the discharge outlet. These features help distribute the material evenly and ensure effective drying by increasing contact with hot air.

2. Thermal system

The thermal system includes a heat source (such as a hot air furnace or burner), hot air ducts, and a fan. The insulation system is made of insulating cotton and galvanized insulation plates to reduce heat loss.

3. Transmission system

The transmission system consists of large gears, small gears, an electric motor, and a gear reducer. The motor drives the drum to rotate through V-belts and gears, ensuring the drum turns at the correct speed for uniform mixing and drying of the material.

4. Feeding and discharging devices

These devices control the entry of wet materials and the discharge of dried materials.

5. Exhaust and dust removal system

The exhaust system removes the moist hot air produced during drying, equipped with a cyclone separator or bag filter to reduce dust emissions.

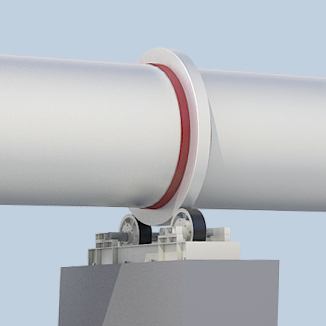

6. Support system

The support system includes rollers, stop wheels, and supporting wheels that support and stabilize the drum, preventing displacement.

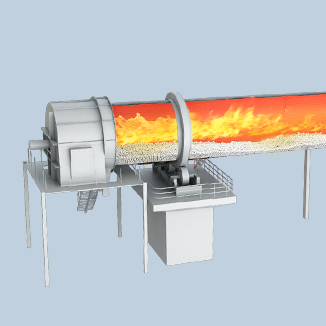

Working principle of the lignite dryer

During operation, wet materials such as lignite, coal slime, and fly ash are fed into the coal dryer via a conveyor belt and then into the drying drum through the feeding device.

Inside the drying drum, a distribution plate helps the material fully contact the hot air for effective heat transfer. Most moisture quickly evaporates, ensuring fast and even drying. The dried material is then discharged through a belt conveyor at the end of the drum.

After heat exchange, exhaust gases containing water vapor and dust pass through a cyclone separator and then into a bag filter for purification. The cleaned exhaust gases are then released, completing the drying process.

Why FTM Machinery lignite dryers?

FTM mechanical lignite dryers are highly effective at reducing the moisture content of high-water coal. They improve coal quality, lower costs, increase efficiency, and support environmental sustainability.

- Superior drying: The low-temperature four-stage drying process reduces coal moisture to below 13%, resulting in significant energy savings.

- Advanced structure: Innovative feeding and discharging systems address issues like blockages and uneven feeding, producing high-quality, low-moisture coal.

- Cost savings: Compared to traditional dryers, this model cuts land and construction costs by 60%. It features durable materials and easy maintenance, reducing downtime.

- Low-temperature output: The dryer maintains an output temperature below 60°C, eliminating the need for additional cooling, which enhances production efficiency and saves on cooling costs.

- Eco-friendly: With strong sealing and advanced dust and noise reduction systems, the dryer meets international environmental standards, ensuring a cleaner and quieter operation.

Customer cases

1. Lignite dryer in Serbia

Project background

A Serbian energy company that generates power from lignite was struggling with high moisture content in their lignite. This led to low energy value, inefficient burning, and issues with transportation and storage.

To solve these problems and cut operational costs, the company decided to use FTM Machinery's lignite dryer for preprocessing.

Solution

FTM Machinery provided a complete lignite drying system, including an efficient coal dryer and dust removal equipment. This setup ensured high-quality drying and met environmental standards.

Equipment specifications

| Parameter | Details |

| Model | φ2.6×24 |

| Output | 27.2–34.0 t/h |

| Heat source | Biomass |

| Feed moisture content | 45% |

| Output moisture content | 8% |

| Thermal efficiency | 85% |

| Main motor power | 55 kW |

Customer feedback

“We are very pleased with the lignite drying system. It has improved our lignite use and helped us meet environmental goals. Thanks to FTM Machinery for their excellent product and service.”

2. Coal dryer in Greece

Project background

A large Greek power company uses bituminous and sub-bituminous coal for power generation but faces high moisture content. To improve efficiency, they decided to adopt FTM Machinery's high-efficiency coal dryer.

Solution

FTM Machinery provided a custom coal drying system using natural gas as the heat source. The system includes an efficient dryer and advanced gas recovery and purification equipment, meeting the company's needs.

Equipment specifications

| Parameter | Details |

| Model | Φ3.2×25 |

| Output | 42.9–53.6 t/h |

| Heat source | Natural gas |

| Feed moisture content | 50% |

| Output moisture content | 12% |

| Thermal efficiency | 90% |

| Main motor power | 90 kW |

Customer feedback

“FTM Machinery's coal drying system greatly improved our fuel efficiency and significantly reduced operating costs. The equipment runs smoothly and is easy to maintain. We look forward to more opportunities in the future.”

Customize your lignite dryers

FTM Machinery offer lignite dryers in various materials, including carbon steel, stainless steel, and special alloys. Choose the dryer base, dust removal system, feeding and discharging devices, and heat source that best fit your needs.

Our dryers come with different heat source options and include an advanced PLC control system and video monitoring for easy operation.

For customized solutions, contact our engineers for expert advice. Contact us