What is a hydraulic briquetting machine?

A hydraulic briquetting machine is a kind of mechanical equipment that uses hydraulic pressure to compress various powdery materials into dense briquettes.

It is a new generation product developed by FTM Machinery in combination with the briquetting development direction at home and abroad, using mature and advanced technology.

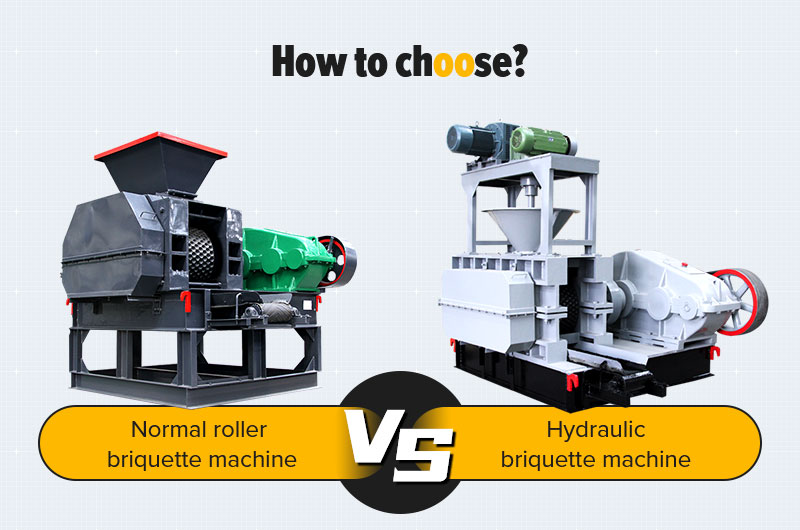

Hydraulic briquetting machine VS ordinary briquetting machine

The biggest difference between a hydraulic briquette machine and an ordinary briquette machine is that the hydraulic briquette press has a hydraulic power system. It can supply a much stronger pressure than normal briquette equipment.

How to choose?

If you have a limited budget and do not have higher requirements for finished products, you can choose an ordinary roller briquetting machine.

If you have a sufficient budget or have the following requirements, choose a hydraulic briquetting machine.

- 1Very suitable for pressing difficult to form materials.

- 2Materials to which no binder can be added due to their natural properties.

- 3To briquette material that can't be mixed with water.

- 4To make the briquette with a higher density.

Compared with the ordinary briquetting machine, the hydraulic briquetting machine has superior performance and a reasonable price. It has gradually become the mainstream product on the market and is chosen by more customers.

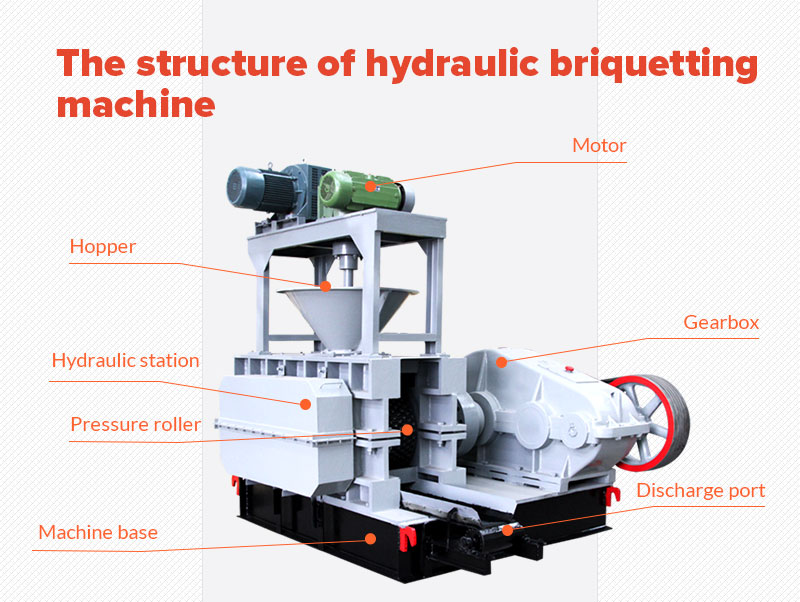

The structure of hydraulic briquetting machine

The main parts of hydraulic briquetting machine are the hopper, motor, hydraulic station, discharge port, gearbox, pressure roller, machine base, and so on. Among them, the pressure roller and hydraulic system are critical components of a hydraulic briquette machine.

1. Pressure roller: A variety of shapes

The rollers of briquette machines adopt high-quality materials to be wear-resistant. Commonly used roller materials are 65Mn and 9Cr2Mo.

The former is low-cost and suitable for soft materials, such as coal powder (coal dust), charcoal powder (charcoal dust), bentonite clay powder, etc. The latter costs more but with higher wear resistance. It is suitable for processing minerals like iron powder, copper powder, chrome power, etc.

FTM Machinery's briquetting molds are diversified to produce square, round, oval, and pillow-shaped briquettes. We can customize special shapes and sizes according to the specific requirements of users.Contact our engineers

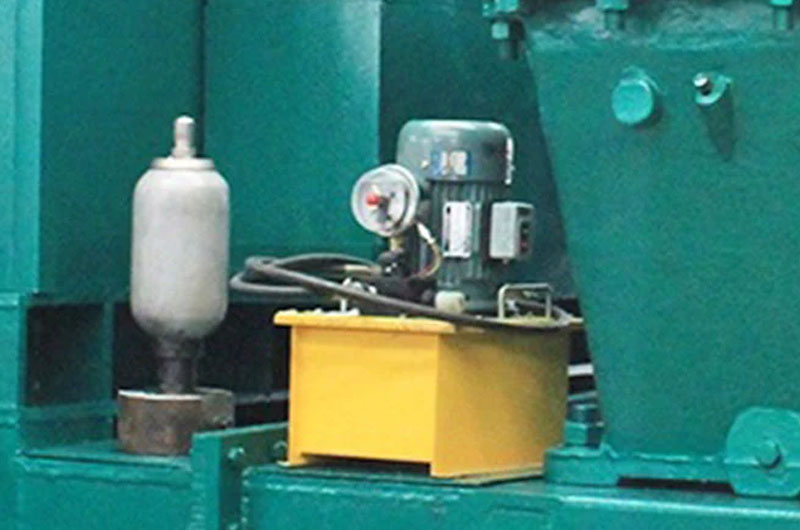

2. Hydraulic system: Provide stronger power

The hydraulic briquette machine adopts a hydraulic system, which is composed of a hydraulic pump, hydraulic oil tank, control valve, oil tank, and other components.

Its main function is to automatically provide stable and strong pressure to the pressure roller and has the function of energy storage and safe overflow.

Why choose FTM Machinery hydraulic briquetting machines?

Hydraulic briquette making machines offer several advantages over other types of briquette machines:

- Good material pressing effect, high ball forming rate, and high-density briquettes are formed;

- The hydraulic station is placed independently. The pressure can be adjusted with the function of overpressure protection;

- All wear parts are welded with wear-resistant alloy to improve performance and life;

- Hydraulic briquetting machines do not need to use adhesives or additives, and the hydraulic system ensures molding;

- In addition, machines have the features of a small footprint, small motor power loss, reliable operation, and convenient maintenance.

FTM Machinery hydraulic briquetting machines for sale at factory prices.Get the Lastest Price

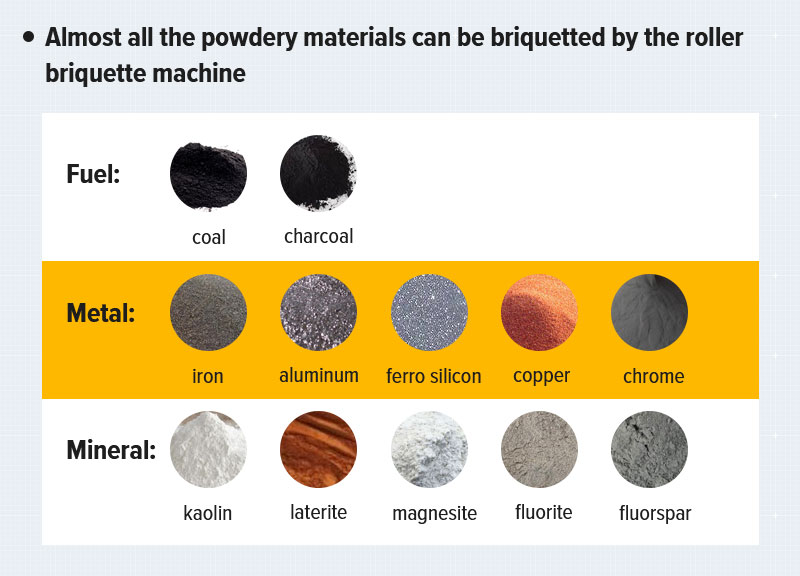

Can all powders be briquetted with a briquette machine?

Almost all the powdery materials can be briquetted, here are some common materials:

- Fuel: Coal powder, carbon powder, charcoal powder (carbonized sawdust, wood shavings, coconut shell, rice husk, straw, etc.)

- Metal: Iron, aluminum, ferrosilicon, copper, chrome, chromite, manganese, nickel, zinc, etc.

- Mineral: Kaolin, laterite, magnesite, fluorite, fluorspar, silicon, dolomite, etc.

How does a hydraulic briquette machine work?

The hydraulic briquette press works on the principle of hydraulic cylinder compression.

The motor rotates to drive the hydraulic pump to work, and the hydraulic oil in the oil tank is transmitted to each cavity of the hydraulic cylinder through the oil pipe. The piston rod of the oil cylinder is driven to move longitudinally, thereby pressing and forming the material in the mold.

FTM Machinery customer cases

1. 20 TPH iron powder briquetting machine in Nigeria

The resources of mineral powder and metal chips in Nigeria are abundant. To improve the comprehensive utilization rate of these materials, users choose metal briquetting machines to improve their use-value.

- Model of briquetting machine: GY1000-500

- Raw material: Iron oxide powder, iron dust

- Capacity: 15–20 TPH

- Shape: Pillow

- Size: 60 mm (in diameter)

- Delivery date: October 3, 2023

Customer feedback:

Israel, the owner of a metal processing company said that he was satisfied with the services such as on-site installation and employee training. The iron ore briquettes were very compact, which reduced the loss during transportation.

2. 10 TPH coal briquette machine in South Africa

In January 2022, a customer from America found FTM Machinery, hoping that we could provide a high-quality briquette machine to process his coal powder. After learning about his needs, our engineers designed a hydraulic ball press production line, mainly including crushing, mixing, briquetting, and drying.

- Model of briquetting machine: GY1000-350

- Raw material: Coal powder, coal dust

- Capacity: 10–15 TPH

- Shape: Egg or round

- Size: 50 mm (in diameter)

- Delivery date: March 4, 2022

Customer feedback:

The procurement manager of a coal briquetting plant said that the coal briquette making machine was running well and rarely broken down, bringing huge economic and social benefits to us.

3. 40 TPH quicklime briquette machine in America

- Model of briquetting machine: GY1200-800

- Raw material: Quicklime, coked lime

- Capacity: 40 TPH

- Shape: Pillow or oval

- Size: 45 mm (in diameter)

- Delivery date: August 15, 2022

Customer feedback:

Kiplitani, an American lime briquette seller, said that the briquettes produced by our hydraulic briquetting press have a uniform density. Lime powder briquetting is widely used in coal, metallurgy, and the chemical industry.

Frequently asked questions about hydraulic briquette machines

1. What are the requirements of briquetting machines for raw materials?

- a. Moisture content: The amount of water has the greatest impact on pressing balls. The ideal water content is controlled at 8–10% to ensure uniform moisture.

- b. Impurity removal: The material should avoid hard lumps, iron blocks, or any sundries that may damage the machine, so as not to damage the rollers and shafts.

- c. Particle size: The raw material should be a suitable particle size. Particles smaller than 1 mm should be controlled between 30–40%; particles of 1–2 mm are controlled between 30–40%; large particles smaller than 3 mm are controlled at about 10%.

2. Do hydraulic briquetting machines require binders or additives?

- In many cases, hydraulic briquetting machines do not require binders or additives. The hydraulic pressure applied during the compression process is often sufficient to bind the particles together.

- However, in actual cases, binders or additives may be added to improve the binding properties of the briquettes.

3. How to maintain my hydraulic briquetting machines?

- To ensure the optimal performance and longevity of a hydraulic briquetting machine, regular maintenance and upkeep are essential.

- a. Regularly inspect hydraulic hoses, fittings, and connections for leaks, wear, or damage.

- b. Replace any damaged or worn-out parts promptly.

- c. Monitor the hydraulic fluid level and quality.

- Read How to Maintain Your Briquette Machine.

Parameter

| Model | Roller Diameter (mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |