Cement grinding isn't just a process step — it's your biggest energy sink. In fact, it can consume up to 70% of your total electricity bill.

If you're still using an outdated cement grinding line, you may be facing issues like rising energy bills, inconsistent product fineness, frequent maintenance shutdowns, and slow production rates.

What if you could change that today?

Two proven cement mills for better grinding results

We've helped hundreds of cement producers upgrade their grinding lines to run cleaner, faster, and cheaper.

Here is how two of the top cement grinding machines compare:

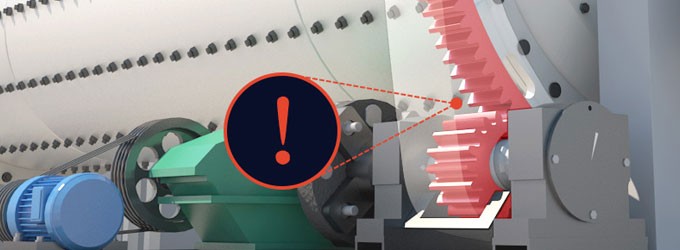

1. Cement ball mill — built to outlast

Our best-selling cement ball mill is designed to run 24/7 with minimal downtime.

With up to 200 tons per hour output, it's trusted by cement plants in America and the Middle East to deliver stable, fine cement at low operation cost.

You will get:

- Robust steel shell that handles high loads without deformation

- High-efficiency liner design to maximize grinding action

- High grinding ratio (up to 300) with fineness up to 200 mesh

- Easy handling of both dry and wet cement grinding, ideal for high-moisture cement

- Suitable for ordinary portland cement and blended cement production

Our best-selling cement ball mill models: Get the latest quote

| Model | Capacity (t/h) | Power (kW) |

| φ900×3000 | 1.1–3.5 | 22 |

| φ2200×7000 | 15–28 | 380 |

| φ2700×4500 | 26–90 | 480 |

| φ4000×5000 | 45–208 | 1500 |

2. Cement vertical grinding mill — one system, four functions

This is not just a mill — it's grinding, drying, separating, and conveying in one.

With pressure up to 10x higher than ball mills, our vertical roller mill grinds faster, finer, and smarter.

It is popular for its energy-saving and space-saving design, especially in large factories.

You will get:

- 30–50% energy savings, cutting over $200,000 in electricity costs annually

- Fineness range from 14 to 400 mesh without overgrinding

- Capable of grinding both cement clinker and raw materials

- 40% smaller footprint compared to traditional systems

- Ideal for high-capacity cement production lines

Our best-selling vertical cement mill models: Get the latest quote

| Model | Capacity (t/h) | Power (kW) |

| HLM17-2Y | 12–20 | 200 |

| HLM24-2Y | 30–45 | 500 |

| HLM35-3Y | 125–165 | 1800 |

| HLM42-4Y | 200–230 | 2500 |

Success stories from real cement grinding plants

At FTM Machinery, we don't just talk numbers — we deliver them. Here are two real-world examples of how upgrading cement grinding systems led to major savings.

Case 1: Ball mill upgrade in Vietnam

A small cement plant in Vietnam was struggling with frequent breakdowns in its aging ball mill system. The repeated failures led to reduced uptime, declining output, and shrinking profit margins.

To turn things around, the plant partnered with FTM Machinery to replace the outdated mill with a modern, high-efficiency cement ball mill.

The results were immediate:

- Production capacity increased to 20 tons per hour

- Improved cement fineness and product consistency

- A low-cost upgrade that boosted profits without major changes

The upgrade helped the plant restore stable output, reduce maintenance headaches, and protect its profits.

Case 2: New vertical cement mill line in Turkey

A major cement manufacturer in Turkey was under pressure to meet growing construction demand while reducing energy costs and staying compliant with new environmental regulations.

They turned to FTM Machinery to engineer and install a brand-new vertical roller mill system tailored to their plant's capacity and operating conditions.

The results were remarkable:

- Saved over $212,000 annually in electricity costs

- Cut maintenance downtime to less than 2 hours per month

- Reduced energy consumption per ton by more than 35%

The new cement grinding line now operates at full capacity with minimal supervision, producing high-consistency cement with lower operational stress.

Ready to upgrade your cement grinding mills?

We've delivered customized grinding solutions to over 100 cement plants worldwide — helping them save energy, increase output, and reduce downtime.

Tell us your daily production, raw material type, and target fineness — and our engineers will provide a free custom solution tailored to your plant. Contact us

Common questions about cement grinding machines

1. How do ball mills and vertical cement mills work in cement grinding plants?

- A ball mill consists of a rotating cylinder (the drum), grinding media (steel balls), and liners. Cement clinker is fed into the mill, where the rotation causes the steel balls to impact and grind the clinker into fine powder until it reaches the required fineness.

- A vertical cement mill uses multiple rollers to press and grind the material on a rotating grinding table. Fine particles are carried upward by airflow for classification, while coarser particles fall back for further grinding.

2. Is a vertical mill better than a traditional ball mill?

- Vertical mills generally offer higher energy efficiency, lower noise, and smaller footprint compared to traditional ball mills. They provide better drying capacity and can handle moisture in raw materials better.

- However, ball mills are simpler, easier to maintain, and more suitable for smaller-scale operations. The choice depends on specific production needs and cost considerations.