Sand is one of the most widely used construction materials in the world. From forming the foundation of buildings to being an essential ingredient in concrete, mortar, and paving mixtures, sand plays a vital role in modern construction.

This blog explores the density of sand, the classification of sand based on particle sizes—coarse sand, medium sand, and fine sand—and practical conversions such as mm to micrometer and mesh to mm, which are crucial for engineers, contractors, and researchers.

Types of sand

Not all sand is the same. Sand can be collected from rivers, oceans, or lakes. It can also be manufactured through mineral sand processing.

Depending on its origin, processing, and particle distribution, different sands are suitable for different construction purposes. Below are the most common types:

1. Natural sand

Natural sand includes river sand, lake sand, and beach sand. Typically grayish-white, it is fine-grained and clean, making it suitable for plastering, masonry, and concrete mixing. River sand is often preferred in reinforced concrete structures due to its rounded particles and smooth texture.

2. Pit sand

Pit sand is extracted from depths of 2–3 meters below the ground surface. It consists mainly of coarse sand particles, which are sharp, angular, and reddish due to iron oxide content. With excellent bonding properties, pit sand is considered ideal for building works that require strong adhesion.

3. M-Sand

The manufactured sand also called M sand, is a factory-produced alternative to natural or river sand for construction. Quartz sand is particularly popular. Made from quartz, it is stable and durable, suitable for use in corrosive environments, making it a popular choice in the construction industry.

4. Concrete sand

Concrete sand is obtained from crushed concrete or aggregates. It is a coarse sand type used in cement mixes, road bases, patios, and leveling layers. Its rough texture improves bonding in concrete mixtures, though it is not as fine as natural plastering sand.

5. Fill sand

Fill sand is used for backfilling and leveling large gaps. It consists of fine particles of eroded rock and aggregates. While it lacks the strength of pit sand or M-sand, it is cost-effective and suitable for sub-base and landfilling projects.

Density of sand

The density of sand refers to the mass of sand per unit volume, usually expressed in kg/m³. It directly influences sand's behavior in compaction, settlement, and its response to moisture.

- Sands with higher density are less likely to shift or settle, providing greater stability.

- Sands with lower density are lighter and more susceptible to movement under load or vibration.

The density of sand varies depending on its environment and water content (dry, moist, or compacted), but is generally between 1,400 and 1,600 kg/m³ or 1.4 and 1.6 g/cm³. Sand density varies depending on its source and quality.

The average density of sand in different states is as follows:

| Condition of Sand | Density of sand (kg/m³) | Notes |

| Loose sand | 1442 | It is dry and has likely been disturbed or moved to break free from its natural accumulation process. |

| Dry sand | 1602 | This sand is in its untouched, natural state and has dried and compacted over time due to gravity and rain. |

| Wet sand | 1922 | It has previously been naturally compacted and is now moist. |

| Packed sand | 1682 | This sand has been compressed manually or mechanically. |

| Wet packed sand | 2082 | In this location, the sand is compressed and nearly saturated with water. |

Generally, the density of sand ranges from 1,400 to 1,600 kg/m³ (1.4–1.6 g/cm³) under dry conditions, but may reach over 2,000 kg/m³ when wet and compacted.

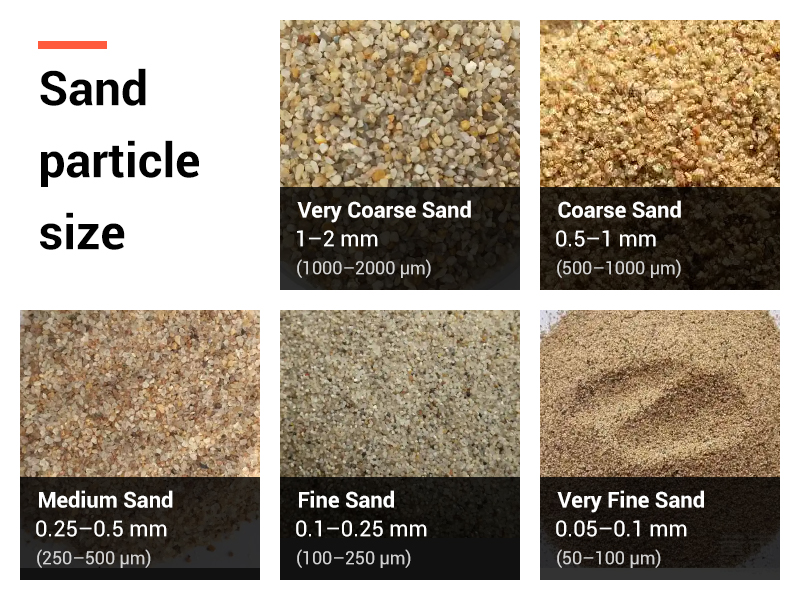

Sand particle size

Sand is classified into categories based on particle size. Sand particles are typically defined by their diameter, with a common international standard using the following ranges:

- Very Coarse Sand: 1–2 mm (1000–2000 µm)

- Coarse Sand: 0.5–1 mm (500–1000 µm)

- Medium Sand: 0.25–0.5 mm (250–500 µm)

- Fine Sand: 0.1–0.25 mm (100–250 µm)

- Very Fine Sand: 0.05–0.1 mm (50–100 µm)

Sand particle size is often measured in micrometers (µm). Understanding unit conversion is important. This conversion helps engineers classify sand particles more precisely when determining grading standards. Conversions: mm to Micrometer

- 1 millimeter (mm) = 1000 micrometers (µm)

- 1 micrometer (µm) = 0.001 millimeters (mm)

This classification is critical because:

- Coarse sand improves strength and drainage.

- Medium sand balances strength and workability.

- Fine sand provides smooth finishes for plastering and brickwork.

Sand particle sizes are also measured using sieves, represented in mesh sizes. Use the approximation that Mesh number × aperture in Microns ≈ 15000. The mesh number indicates the number of openings per linear inch of sieve.

- A higher mesh number means finer particles.

- A lower mesh number means coarser particles.

| US Mesh | Micron | Inches |

| 4 | 4,750 μm | 0.187 |

| 5 | 4,000 μm | 0.157 |

| 6 | 3,350 μm | 0.132 |

| 7 | 2,800 μm | 0.111 |

| 8 | 2,360 μm | 0.0937 |

| 10 | 2,000 μm | 0.0787 |

| 12 | 1,700 μm | 0.0661 |

| 14 | 1,400 μm | 0.0555 |

| 16 | 1,200 μm | 0.0473 |

| 18 | 1,000 μm | 0.0394 |

| 20 | 850 μm | 0.0331 |

For more mesh to mm conversion, you could check this chart: Mesh Sizing Chart.

Density and size of sand are important for construction

Understanding the density of sand and its size distribution is essential for:

- Concrete Mix Design – Correct sand size improves strength and reduces voids.

- Mortar Workability – Fine sand provides smooth plaster finishes, while coarse sand adds strength.

- Drainage Applications – Coarse sand ensures better water permeability.

- Foundation Compaction – Higher density sands reduce settlement risks.

- Cost Efficiency – Properly graded sand reduces cement consumption by filling voids effectively.

Conclusion

Sand can directly impact building quality. By understanding sand density, classifying it as coarse, medium, and fine, and applying unit conversions (e.g., millimeters to microns, mesh to millimeters), engineers can make improve the performance and durability of their construction projects.

Whether you are selecting sand for concrete, plastering, or filling, these properties and conversions ensure the right material is used for the right job.