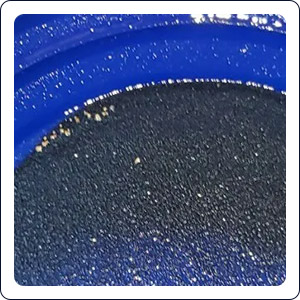

Black sand is a common type of placer deposit, typically found in riverbeds, riverbanks, and sandbars. It often coexists with alluvial gold, a type of placer gold found in sediments containing tiny gold particles.

Black sand resources are abundant in the Philippines, Indonesia, South Africa, Morocco, Nigeria, Guinea and other countries.

You may want to know:

Black sand color: Black or dark gray

Black sand density: About 5

Black sand specific gravity: The minerals that make up black sand have a specific gravity of 4-5, and the specific gravity of gold is 19.

Black sand composition: Mainly magnetic minerals like magnetite and hematite, with small amounts of heavy minerals such as chromite, platinum, lead, cassiterite, and zircon.

Traditionally, gold miners use gold pans, sluice boxes and rocker boxes to obtain gold from black sand, but these basic equipment can only handle a limited amount of black sand and are time-consuming and labor-intensive, resulting in a waste of gold resources.

Here are four practical methods for extracting gold from black sand, designed to help you utilize these rich resources more effectively and increase your wealth.

4 methods to extract gold from black sand

1. Gold shaker table separation method Get Expert Advice

This is the simplest and lowest cost method of gravity separation.

You only need to place the black sand on the shaker without any operation. The shaker will accelerate the separation of gold particles and impurities in the continuous vibration.

Since the specific gravity of the heavy minerals in black sand ranges from 4 to 5, and that of gold is around 19, which is nearly five times heavier, the gold particles will settle at the bottom of the shaker table while the impurities float to the top.

In this way, you can collect gold particles and refine them into gold products with higher purity.

If your budget is limited or the gold particles to be separated are less than 1 mm, we recommend that you use this method to obtain gold.

2. Spiral chute gold separation method Get Expert Advice

This is another highly efficient gravity separation method that uses the water flow and gravity of the spiral chute.

When black sand enters the spiral chute, the heavier gold particles concentrate in the center of the chute, while lighter impurities are washed to the outer edges.

If you need to process a large amount of black sand, we strongly recommend this method. The spiral chute can handle 40 tons of black sand per hour, which is much higher than the shaker table, making it especially popular with medium to large-scale gold mining operations.

3. Magnetic separation method Get Expert Advice

This method is suitable for factories with sufficient budget and high requirements for gold particles.

These experienced factories will first use a small magnetic separator to remove magnetic minerals such as magnetite from black sand, and then use gravity separation to obtain gold.

In black sand gold deposits, gold particles can be influenced by magnetic minerals or even completely enclosed by them.

4. Wet pan mill gold release method Get Expert Advice

If your black sand contains large metal particles, do not miss this method.

Using a wet pan mill to grind the black sand can increase the surface area of the gold and release small amounts of gold. When combined with magnetic separators and gravity separation equipment, this method can maximize gold recovery.

This combined approach not only increases the efficiency of gold extraction but also ensures the purity and quality of the final product.

South Africa black sand processing plant

At a black sand processing plant in South Africa, gold was successfully separated from black sand using shaker tables.

- Raw materials: Black sand, magnetite, hematite, chromite, zircon

- Capacity: 100 tons of black sand per day

- Equipment configuration: 2 shaker tables, 1 trommel screen

Their process flow:

- 1 The trommel screen is first used to remove gravel and impurities.

- 2 The black sand concentrate is then sent to the shaker tables for separation, where heavier materials like gold particles settle at the bottom.

- 3 The separated gold particles are collected and further processed to obtain high-purity gold products.

Factory Operations Director Romero Shares:

"Since we started using FTM Machinery's equipment, we process 100 tons of black sand daily with just two shaker tables. Their efficiency and reliability are truly impressive. If you want to boost your productivity, FTM Machinery is a great choice."