Whether in mining, construction, or aggregate production, choosing between cone and impact crushers is key for secondary and tertiary crushing—they handle similar tasks but perform differently.

In this blog, we will explore six differences between cone crushers and impact crushers, helping you decide which rock crusher is better for your rock crushing plant.

1. Structure and working principle

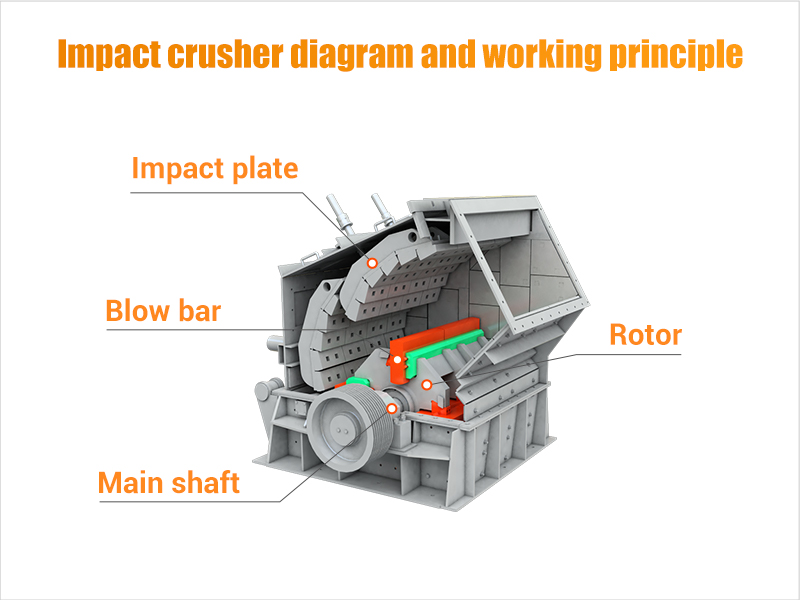

Impact crusher:

FTM Machinery Impact Crusher is a vertical shaft crusher. It can also be designed into a mobile or portable impact crusher if you need the mobile crushing. The key parts mainly include the blow bar, rotor, impact plate, and main shaft. The rotor is equipped with a high-speed rotating hammer.

The main difference between the impact crusher and the cone crusher is the type of crushing force. The impact crusher working principle is as follows:

It uses high-speed impact force where material is fed into the crushing chamber and struck by the hammer mounted on the rotor.

The resulting force fractures the rock against the impact plate.

The gap between the rotor and the impact plate can be adjusted to control the output size.

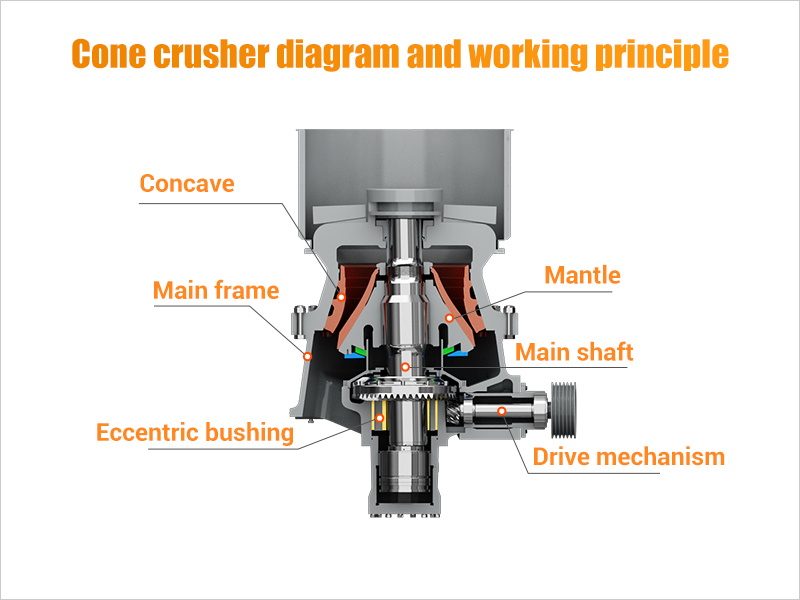

Cone crusher:

FTM Machinery offers the single-cylinder cone crusher, multi-cylinder hydraulic cone crusher, fully hydraulic cone crusher, and mobile cone crusher. These crusher machines all consist of the main shaft, mantle, concave, eccentric bushing, main frame, and drive mechanism.

How does a cone crusher work?

It uses compression force to squeeze, shear and grind rock, and is ideal for tough applications.

The rotating mantle (also called rotating cone) moves within a fixed concave surface (also called bowl liner).

As the material enters the crushing chamber, it is repeatedly compressed between the mantle and the concave surface, gradually breaking into smaller sizes.

2. Applicable materials

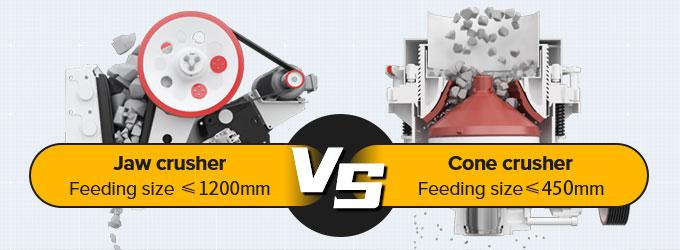

As two common secondary and tertiary crushers, impact crushers and cone crushers crush materials with different rock hardness and feed particle sizes.

Impact crushers are better for:

- Soft to medium-hard, brittle materials (compressive strength not exceeding 350 MPa), such as limestone, gypsum, coal, shale, dolomite, calcite, etc.

- Lightweight aggregates, shaping, and applications requiring cubic end products

- Maximum feed size: 800 mm

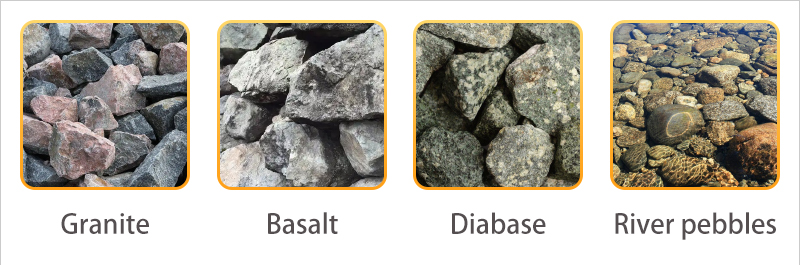

Cone crushers are ideal for:

- Hard rocks and minerals, such as granite, basalt, diabase, limestone, river pebbles, iron ore, copper ore, gold ore, quartz, marble, bauxite, and gravel

- Construction waste like recycled concrete and asphalt

- High-strength construction aggregates and other medium to hard and abrasive materials

- Maximum feed size: 480 mm

In short, if you are working with very hard stone or metallic ores, a cone crusher is more efficient. For softer rocks or recycled materials, an impact crusher offers better flexibility.

3. Discharge particle size and quality

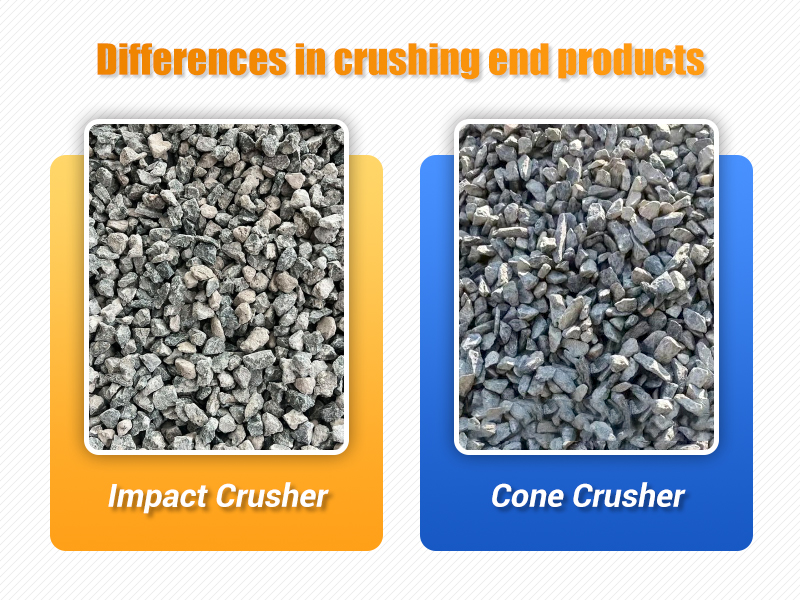

Cone crushers produce finer material than impact crushers.

- In actual production, cone crushers are often used in mineral processing, with the output size between 3 and 64 mm.

- Impact crushers are often used in building materials and construction projects. The output size ranges from 2 to 10 mm.

Impact crushers produce cubic particles with better shape, smaller edges and corners, and better quality. This makes it the first choice when appearance and particle shape are critical, such as in road base, concrete aggregate, or asphalt applications.

The cone rock crusher can also produce high-quality aggregates, but its finished particles tend to be slender, needle-like, or flake-like. For certain applications like high-strength concrete, this shape may not be ideal unless post-processing is applied.

4. Production capacity

In terms of production capacity, the crushing performance of the cone crusher is better than that of the impact crusher of the same size. Its output can reach 2,181 tons/hour. The impact crusher can produce 30 to 2,000 tons per hour when crushing soft materials.

Because the cone crusher also has the advantages of higher crushing, stable production and low operating cost, it is often used for continuous crushing of large amounts of materials and is often used in the crushing lines of large mines and quarries.

5. Costs and maintenance

Impact crusher:

The initial purchase cost of an impact crusher is lower, but the maintenance cost is higher. The hammer and impact plate wear faster, especially when crushing hard rocks, so they need to be maintained and replaced more frequently than the cone crusher.

Cone crusher:

The price of a cone crusher is higher than that of an impact crusher, but it has a sturdy structure and a lower wear rate.

- Although the liner will wear over time, its service life is longer, avoiding the trouble of frequent replacement of parts.

- Equipped with an advanced hydraulic system and lubrication system for dual protection, it allows precise adjustment of the discharge opening and provides overload protection, ensuring safe and continuous operation.

FTM Machinery recommends:

- Hard rock: Cone crusher is more economical in the long run.

- Soft rock or recyclable material: Impact crusher may be cheaper initially, but wear part costs are expected to be higher.

6. Environmental and energy efficiency

Impact crusher:

An impact crusher consumes more energy when crushing hard rocks and minerals, but has higher crushing efficiency when crushing softer materials. It will produce some dust and noise due to high-speed collision.

Cone crusher:

A cone crusher is typically more energy-efficient due to its compression-style crushing. And during the crushing process, the positive pressure system can block dust and debris, thus keeping the parts clean and generating less dust and noise.

Conclusion

When choosing between a cone crusher and an impact crusher, it ultimately comes down to your material, output requirements, budget, and operational goals.

- If your primary priority is to produce well-shaped aggregate, choose an impact crusher.

- If you are dealing with hard, abrasive materials and require high output for secondary or tertiary crushing, choose a cone crusher.

Understanding the performance, working principles, costs, and application scenarios of each type of rock crushing equipment can help you make smarter, more informed decisions for your crushing needs.