Customers engaged in quarrying, mining, road construction, or cement industries in Russia often face the same question:

"What kind of crushing equipment should I choose to best suit my local material, climate, and production needs?"

These projects frequently encounter a common set of challenges:

- Most projects are typically located in remote areas with high labor costs

- Extreme winter conditions reaching -40°C, requiring cold-resistant machinery

- Tight investment cycles demanding high-efficiency, low-maintenance equipment

To address these issues, we've analyzed real customer cases and local stone characteristics to help you select the right crushing equipment—and reduce investment risks.

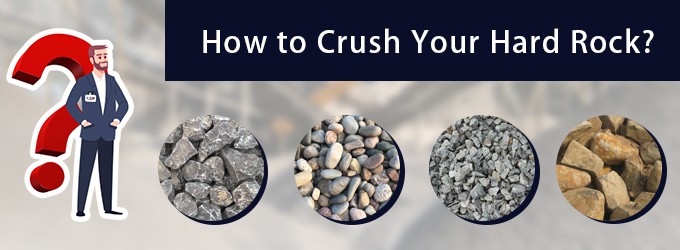

Common types of stone in Russia

FTM Machinery has crushing equipment in use in many regions of Russia. The properties of stones from customers in different regions vary greatly:

| Srone type | Hardness(Mohs) | Abrasiveness | Characteristics |

| Granite | 6-7 | High | High hardness, quick equipment wear |

| Reinforced concrete | 6-7 | High | Contains rebar, requires iron remover |

| Limestone | 3-4 | Low | Easy to crush, more dust |

| River pebbles | 6-7 | High | High silica, suitable for shaping |

| Construction waste | 2-7 | Medium | Mixed composition, varied sizes |

| Gravel(recycled aggregate) | 5-6 | Medium | Diverse sources, more impurities |

| Slag (blast furnace slag) | 5-6 | Medium | Dense, used for road base |

The hardness and abrasiveness of the stone will directly affect the choice of crushing equipment. Many customers will ask the following common questions when choosing crushing equipment:

- What is the maximum size of stone that the crusher can crush?

- How small can the stone become after crushing?

- Should I choose a fixed or mobile crusher?

We are here to help answer all of these questions.

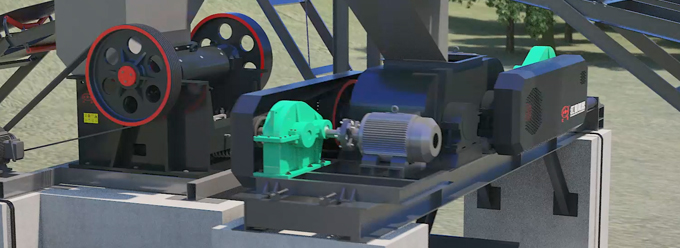

Basic equipment of a crushing plant

In fact, crushing is a multi-stage process, with each machine performing a specific role. A complete crushing line typically includes:

- Primary crusher: Performs coarse crushing of raw stone (up to 500–1000mm) at the beginning of the line.

- Secondary/fine crushers: Handles second or third-stage crushing, producing output sizes of 5–40mm as required.

- Screening system: Sorts final products by size, usually with 2–4 layers of vibrating screens.

- Conveying system: Belt conveyors link all equipment to ensure continuous and stable material flow.

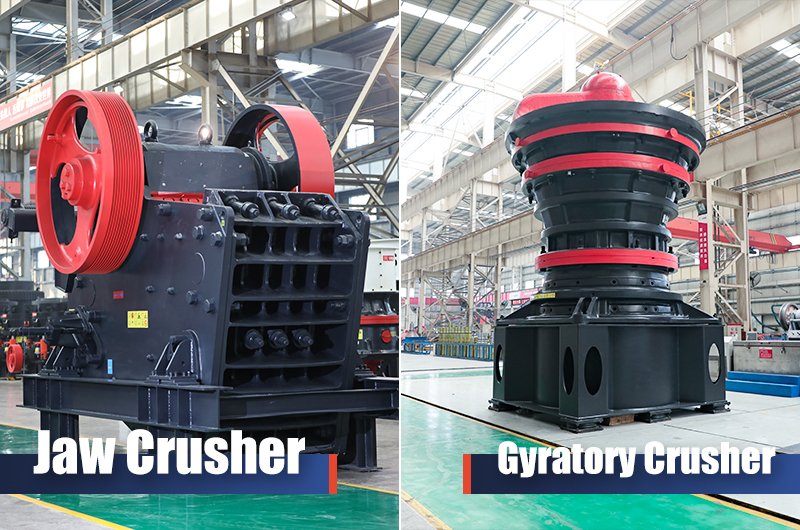

Primary crushing equipment Get a quote

| Equipment type | Input size | Output size | Features |

| Jaw crusher | ≤1200 mm | 10–350 mm | Versatile, simple structure, cost-effective |

| Gyratory crusher | ≤1300 mm | 140–250 mm | Ideal for large-scale mining, high throughput, continuous crushing ability |

Selection advice:

- For small to medium-scale projects (50–300 TPH), a mid-sized jaw crusher is sufficient to meet most primary crushing needs.

- For fixed plants with large rock sizes and high daily output, a gyratory crusher is recommended. It can handle over 2000 tons per hour.

Secondary and tertiary crushing Get a quote

| Equipment type | Input size | Output size | Features |

| Impact crusher | ≤800 mm | 10–40 mm | Excellent particle shape, ideal for concrete aggregates, cost-effective |

| Cone crusher | ≤480 mm | 5–40 mm | Strong capacity for hard rock, longer wear life |

| VSI sand maker | <50 mm | 0–5 mm / 5–10 mm | Best for sand production and shaping, precise control over particle size |

Selection advice:

- For softer or wet stones with a focus on cost-efficiency, choose an impact crusher.

- For hard stone or high wear-resistance requirements, choose a cone crusher.

- For shaping and sand-making applications, a VSI sand maker is the best choice.

Mobile crushing equipment Get a quote

Mobile crushing equipment are especially popular in Russia due to their outstanding performance in remote, cold, and mobile-intensive projects.

Mobile crushers offer the following advantages:

- Meets a wide range of capacity needs: 50TPH, 100TPH, 150TPH, 200TPH and more

- All systems are integrated into a single mobile platform—no foundation needed, ready to work on arrival

- Easy to transport, enabling quick relocation between job sites

- Compatible with various crusher types: jaw, impact, or cone crushers

Comparison of two common mobile crusher types:

| Feature | Wheeled mobile crusher | Tracked mobile crusher |

| Mobility | Towed by trailer | Self-driven, remote control |

| Terrain | Flat, urban sites | Mines, rugged or frozen terrain |

| Cost | Relatively cheap, simple structure | Higher cost, designed for heavy-duty use |

| Applications | Construction waste, reinforced concrete, recycled aggregates | Ore crushing, harsh and cold regions |

Screening equipment Get a quote

| Aspect | Specification | Features |

| Screen layers | 2–4 layers | Multi-level particle size screening, such as 0–5 mm, 5–10 mm, 10–20 mm, etc. |

| Screen media | Wire mesh, nylon, bar screen | Replaceable per material type |

Placed after crushing stages, vibrating screens efficiently sort material by size. A triple-deck or higher configuration is recommended for better output control.

Fixed vs. mobile crushing plants: how to choose?

Here's a quick comparison to help you choose the right crushing plant for your project.

| Aspect | Fixed crushing crusher | Mobile crushing crusher |

| Initial investment | Lower | 10–15% higher than fixed line |

| Civil work | Requires concrete foundation | No foundation needed, fast deployment |

| Mobility | Stationary | Relocatable, ideal for seasonal or short-term use |

| Maintenance | Decentralized components, easier to repair | Integrated design, centralized management |

| Suitable places | Quarries, cement plants, permanent sites | Demolition, remote mining sites, temporary projects |

The following are our customer cases in Russia

- Moscow suburban road reconstruction: Wheeled mobile plant with impact crusher and vibrating screen, fast deployment for segmented roadwork.

- Siberian open-pit mining site: Crawler-type mobile crushing & screening station, designed for year-round operation with no need for permanent foundation.

- Ural limestone quarry for cement production: Fixed crushing line for long-term output, equipped with a jaw crusher and cone crusher combination.

Whether it is a fixed crusher or a mobile crusher, we provide multiple models to support a variety of production capacity requirements from small to large, such as:

- Small-scale quarry (Daily output: 50 tons)

- Construction waste recycling (Up to 200 tons/day)

- Mid-to-large mining projects (Over 1,000 tons/day)

Contact us today for free one-on-one equipment selection advice. Contact us

After-sales service guarantee

- 1 Installation and commissioning: On-site installation guidance and commissioning to ensure smooth production.

- 2 Operation training: Operator training on machine use and basic maintenance.

- 3 Spare parts support: Spare parts in stock for quick replacement.

- 4 Remote and inspection services: Regular inspections and remote support to reduce downtime.

- 5 Quick response mechanism: 24/7 hotline and on-site support within 72 hours in key regions.