What is diabase?

Diabase, also known as dolerite, is a dark green to black, fine- to medium-grained igneous rock with a dense structure and a Mohs hardness of 6–7. It is harder and more wear-resistant than common rocks like limestone or sandstone.

Because of its strength and clean texture, diabase is a great material for making crushed sand. It has:

- Good shape and consistent grain size

- Low mud content and balanced gradation

- Strong and durable—perfect for high-strength concrete

- Widely available with stable supply

Crushed diabase is often used in construction projects like concrete aggregates, railway ballast and subgrade, road base layers, and port foundations.

How is diabase crushed and made into sand?

When investing in diabase crushing and sand production, customers often focus on a few key questions:

- Is the equipment durable?

- Does the final sand have a good shape?

- Can the output meet industry quality standards?

- Will the production line actually make money?

Based on successful projects worldwide, FTM Machinery has developed a high-yield and efficient diabase crushing & sand making solution.

From raw rock to high-quality finished sand, a complete diabase crushing plant typically includes jaw crushers, cone crushers, VSI sand makers and vibrating screens.

Step 1: Jaw crusher → primary crushing

This stage breaks large diabase rocks into smaller pieces (around 100 mm), preparing them for the next crushing stage.

Recommended machine: PE/HD series jaw crusher

Handles raw diabase up to 1000 mm in diameter

Large crushing ratio (up to 10:1), shapes rocks in one pass

Heavy-duty flywheel + high manganese steel jaw plates = long service life

Easy to maintain – 1 person can change parts

Ideal for hard materials like basalt, diabase, and granite

Capacity: 1–60 tons/hour (small jaw crusher), 500+ tons/hour (large jaw crusher)

Step 2: Cone crusher or heavy hammer crusher → secondary / fine crushing

Cone crushers are ideal for high-hardness rocks like diabase. They offer high efficiency and excellent shape control. Heavy hammer crushers cost less, but wear out faster—best for smaller operations (less than 150,000 tons/year).

Recommended machine: SC series single-cylinder hydraulic cone crusher

Multiple cavity options (fine / medium / coarse), output size: 5–40 mm

Fully hydraulic system: one-click chamber clearing & overload protection

Laminated crushing = less time in the chamber → less dust, better quality

Capacity: 25–90 tons/hour (small cone crusher), 300+ tons/hour (large cone crusher)

Step 3: VSI sand making machine → sand shaping & finishing

At this stage, medium-sized diabase is turned into high-quality manufactured sand (0–5 mm), with better shape and gradation.

Recommended machine: VSI series sand making machine

Sand yield over 90%, with cubical shape and low flake content

Output size: 0–5 mm, great particle shape

Saves 30–50% energy vs. traditional sand makers

Can be paired with dust collectors to keep fine powder <10%, meeting high-grade sand standards

Step 4: Vibrating screen → screening & grading

Vibrating screens remove dust and fine particles. When paired with a sand washer, they improve cleanliness and help control silt content—essential for producing high-grade manufactured sand.

Recommended machine: circular vibrating screen

2–4 deck options, screen sizes like 0–5 mm, 5–10 mm, 10–20 mm, etc.

High screening accuracy (>95%), large capacity, 24/7 operation

Works with a sand washer to keep silt content <3%

After going through advanced crushing and sand-making machines, diabase sand has excellent shape and size. It also commands a higher market price (approx. $60–150/ton), giving you a competitive edge.

Here are proven diabase crushing and sand-making setups from FTM Machinery, customized for different production scales to ensure high returns.

| Output | Suggested equipment setup | Ideal for |

| 3–15 t/h | Small jaw crusher, roller crusher, screening, washing system | Small sand producers with access to hard rock, looking to start profitably |

| 50–150 t/h | Jaw crusher, heavy hammer crusher, VSI sand maker, 3-deck vibrating screen | Medium-scale plants needing better product quality or higher margins |

| 200+ t/h | Jaw crusher, cone crusher, VSI sand maker, 4-deck screen, sand washing system | Large operations upgrading to clean, energy-efficient, high-performance lines |

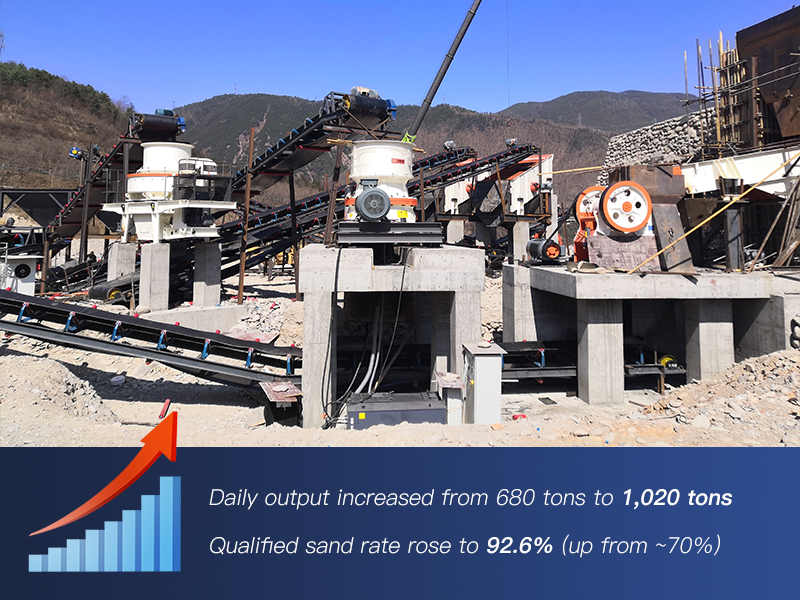

Customer story: how diabase turned into "gold"

A customer in Uzbekistan owned a diabase quarry. They were using a hammer crusher and impact crusher combo for sand making, but it led to high wear costs, frequent downtime, and only about 70% of the final product met quality standards.

Our engineering team redesigned the entire setup—replacing their system with a jaw crusher, cone crusher, and VSI sand maker, supported by multi-deck screening and centralized control.

Results:

- Daily output increased from 680 tons to 1,020 tons

- Qualified sand rate rose to 92.6% (up from ~70%)

- Selling price per ton increased by 20%, with a major boost in annual profits

- Maintenance costs dropped by 45%, and downtime was significantly reduced

More customers are choosing FTM Machinery because we offer:

- 40+ years of experience in crushing and sand-making equipment

- 1,000+ production lines delivered in over 120 countries

- On-site installation, training, and responsive after-sales service

- Free custom plans based on your budget and site conditions

- Fast ROI: most clients break even within 3–6 months

We don't just sell machines—we help you turn rock into revenue.

Contact us today for a free quote and custom solution.

Diabase FAQs

1. Is a diabase crushing line expensive? Are there small-scale options?

- The investment can be large or small—our solutions are flexible and fully customizable. We offer setups ranging from just a few dozen tons per day to several thousand. For startups or sites with limited resources, a compact setup with just one or two machines is available and cost-effective.

2. What is the difference between diabase, basalt, and gabbro?

- Diabase is a shallow intrusive igneous rock with a fine-grained, dense texture. It has a Mohs hardness of 6–7, making it strong, wear-resistant, and easy to process—an excellent, cost-effective material for manufactured sand.

- Basalt is an extrusive volcanic rock with similar hardness but higher density. It's more difficult to crush and requires highly wear-resistant equipment—ideal for high-end aggregate production.

- Gabbro is a deep intrusive rock with coarser grains and slightly lower hardness. It tends to produce more flaky particles during crushing, which can reduce sand yield. Still, it remains a viable source for medium- to high-grade sand and aggregate.