In mineral processing and powder production, Raymond mills and ball mills are two of the most widely used grinding machines.

So which one is the better choice? The answer depends entirely on your material properties, required fineness, production capacity, and operating budget.

In this article, we compare Raymond mills and ball mills from several key aspects, helping you select the most suitable grinding solution for your application.

Structure and working principle

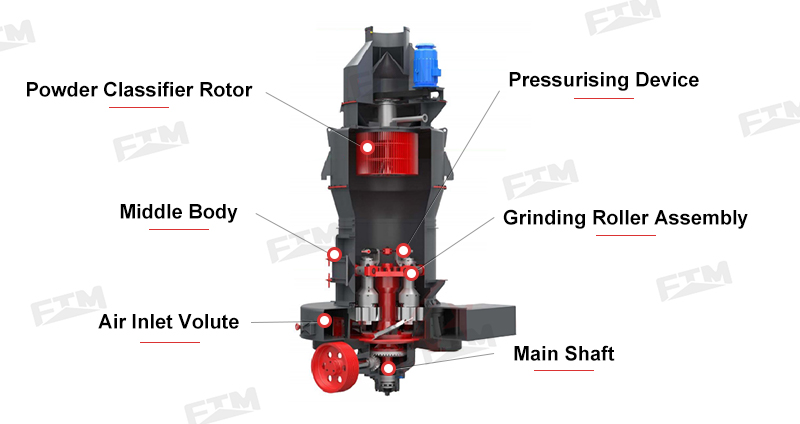

Raymond Mill

A Raymond mill features a vertical and compact structure, integrating crushing, drying, grinding, and classification into one system. Its small footprint makes it especially suitable for plants with limited space or projects aiming to reduce civil construction costs.

In our optimized Raymond mill design, the classifier has been upgraded to a cage-type classifier, offering better sealing performance, lower noise levels, and finer, more uniform finished powder.

Raymond mill working principle: Material is ground between the grinding rollers and grinding ring through pressure and shear force. An airflow system carries qualified powder to the classifier, ensuring consistent particle size, while oversized material is returned for further grinding.

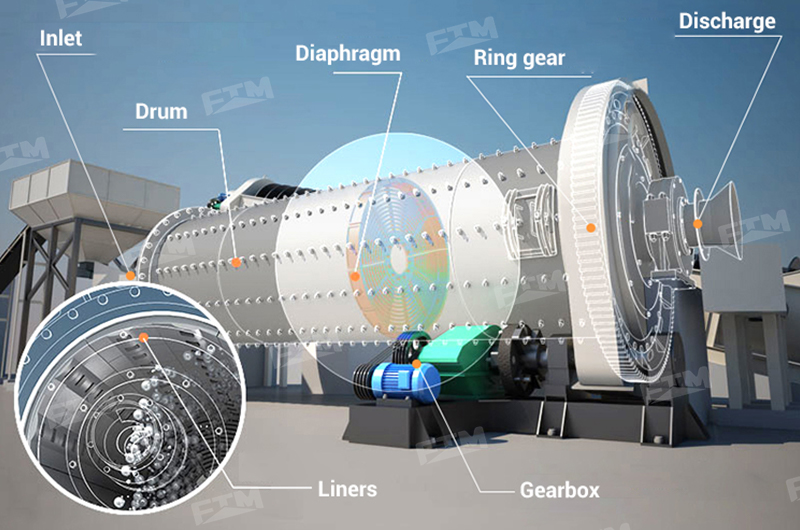

Ball Mill

A ball mill is a horizontal rotating cylinder filled with steel balls. It is a heavy-duty machine that requires a solid concrete foundation and is designed for continuous 24/7 operation in industrial environments.

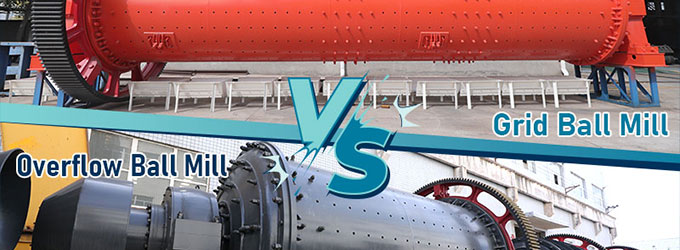

Based on discharge structure, ball mills are commonly classified as:

- Grate-type ball mill: Suitable for primary grinding stages where the product size needs to reach approximately 0.2–0.3 mm, commonly used in the first stage of grinding circuits.

- Overflow-type ball mill: Produces finer material, usually below 0.2 mm, and is widely used in secondary grinding stages.

Ball mill working principle: As the cylinder rotates, centrifugal and frictional forces lift the steel balls and material to a certain height before they fall. Continuous impact and abrasion between balls and material provide strong grinding force, making ball mills ideal for hard and abrasive materials.

Suitable materials

Raymond Mill

Raymond mills are designed for soft to medium-hard, non-metallic materials, typically with low abrasiveness and low moisture content.

- Non-metallic minerals: limestone, gypsum, barite, quartz, calcite, talc, marble, dolomite, coal gangue, bentonite, fluorite, bauxite, activated carbon, potassium feldspar, granite, ceramics, and more

- Industrial by-products: water slag, steel slag, furnace slag, fly ash, coal ash, and similar materials

Raymond mills are especially suitable for limestone grinding, gypsum powder production, and barite processing in non-metallic mineral industries. Explore our grinding solutions for different materials:

Ball Mill

Ball mills perform better when processing hard, abrasive, or metallic materials, especially in wet grinding conditions where Raymond mills are not suitable.

Ball mills can grind both metallic ores and non-metallic materials:

- Metal ores: gold ore, copper ore, iron ore, chrome ore, and other metallic minerals

- Industrial and chemical materials: quartz sand, feldspar, limestone, marble, zircon sand, cement clinker, slag, furnace slag, and similar materials

Wet ball mills are widely used in mineral beneficiation plants, while dry ball mills are commonly applied in hard material grinding.

Production capacity

Raymond Mill

Raymond mills are best suited for small to medium-scale powder production. Modern upgraded models support continuous operation, with typical capacities ranging from 0.4 to 40 t/h.

They are widely used by regional powder producers and industrial plants focusing on non-metallic materials.

Most popular Raymond mill models: Get the latest quote

| Model | Capacity (t/h) | Power (kW) |

| 4119 | 1–10 | 75 |

| 4525 | 2–22 | 132 |

Ball Mill

Ball mills are designed for medium to large-scale industrial production, offering significantly higher throughput. Typical capacity ranges from 0.65 to 615 t/h.

As production capacity increases, ball mills become the preferred choice due to their scalability and continuous operation capability.

Most popular ball mill models: Get the latest quote

| Model | Capacity (t/h) | Power (kW) |

| φ2100×3000 | 6.5–36 | 155 |

| φ2700×4500 | 26–90 | 480 |

Powder fineness

Raymond mills can produce finer and more uniform powder than ball mills, with a finished fineness ranging from 80–800 mesh (0.18–0.015 mm). They are ideal for applications that require high particle size consistency, such as building materials, fillers, coatings, and chemical processing.

Ball mills produce a broader particle size distribution and are mainly used for coarse grinding and primary size reduction. The typical feed size is below 25 mm, and the finished product size usually falls within 20–200 mesh (0.074–0.89 mm).

Costs and maintenance

Raymond mill

Raymond mills use a vertical, integrated design that combines grinding and classification, resulting in lower energy consumption than ball mills. For medium-hard materials like limestone or talc, this means lower electricity costs.

Our upgraded Raymond mills are 15–20% more energy-efficient than traditional models. Wear parts like rollers and rings are easy to replace, and routine maintenance is simple—often handled by a single operator.

Ball mill

Although ball mills may have higher energy consumption per ton, their large processing capacity—especially in large-scale continuous operations (such as thousands of tons per day)—often balances overall energy efficiency in industrial projects.

Ball mills require regular maintenance due to their heavy workload, including routine monitoring and replacement of liners and grinding media.

We provide high-quality wear parts and long-term technical support to help minimize downtime and extend the service life of the equipment.

Which grinding solution should you choose?

Scenario A

"I need to produce 200-mesh limestone powder for a local construction project, with a capacity of about 5–10 tons per hour."

Our recommendation: Raymond Mill

It offers low operating costs, high efficiency for soft mineral processing, and an easy-to-manage automated system, making it an ideal solution for this application.

Scenario B

"I am processing abrasive iron ore for a large-scale mining operation, with a daily output of over 1,000 tons."

Our recommendation: Ball Mill

This application requires the strong grinding force of steel media. Our ball mills feature wear-resistant liners and are designed to minimize downtime in continuous, heavy-duty operations.

Scenario C

"I want to process gold ore for beneficiation, with a feed size below 20 mm and a capacity of 30–50 t/h."

Our recommendation: Ball Mill

Ball mills are commonly used in gold beneficiation plants, especially in wet grinding circuits, delivering reliable performance for downstream separation processes.

Your professional grinding equipment partner

As an experienced grinding equipment manufacturer, we offer:

- Raymond mills, ball mills, rod mills, SAG mills, and AG mills

- Customized solutions based on material and capacity

- Complete production line design

- In-house manufacturing with strict quality control

- Global export service and technical support

Contact us today with your material type, required fineness, and capacity. Our engineers will provide a tailored grinding solution and competitive pricing for your project.