Gypsum is a common mineral, primarily composed of calcium sulfate (CaSO4·2H2O). Due to its excellent fire resistance, soundproofing, and humidity regulation properties, gypsum is widely used to make products like gypsum boards, gypsum powder, plaster bandages, and fertilizers.

Common gypsum products are typically made from gypsum rock, which is crushed and ground into gypsum powder of varying fineness to meet the needs of industries such as construction, healthcare, and agriculture.

The gypsum powder processing plant

Gypsum powder production lines take natural raw gypsum (dihydrate gypsum) and transform it into various types of gypsum powder, such as construction gypsum powder and hard gypsum powder, through processes like crushing, grinding, and calcination.

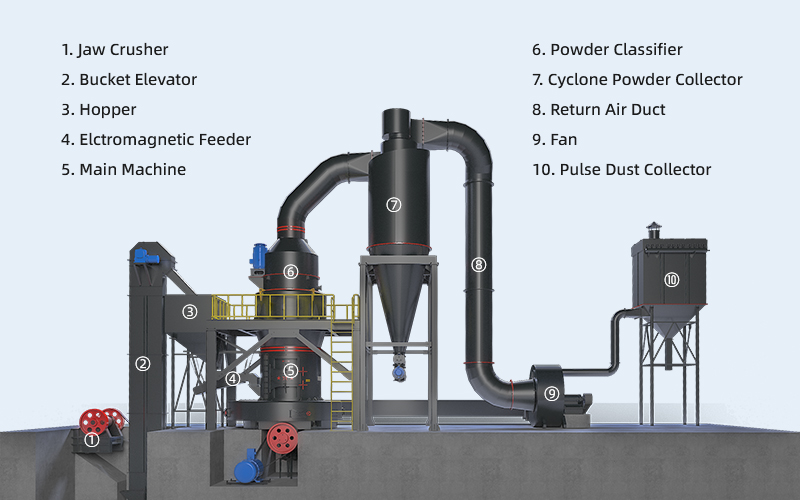

Complete gypsum grinding process flow:

- 1 Gypsum ore is processed by jaw crushers and hammer crushers to reduce the particle size to below 25 mm.

- 2 Next, different types of grinding mills are used for fine grinding.

- 3 After classification by a powder selector, the qualified powder is collected by a cyclone collector and sent to a rotary kiln for calcination.

- 4 At around 150°C, mature gypsum is formed, and when heated above 170°C, hard gypsum is produced.

- 5 Finally, the gypsum powder is cooled and packaged for sale.

The production line is equipped with a pulse-jet dust collector, designed to capture dust and impurities, improving the cleanliness of the work environment.

This equipment not only protects worker health but also ensures the high quality of the gypsum powder, meeting the needs of manufacturers in construction materials, wallboard production, and fertilizers.

You may be interested in:

Gypsum powder mills

Grinding mills are the core of the entire production line, directly affecting the fineness and quality of gypsum powder.

Appropriate grinding equipment must be selected during the gypsum grinding stage, depending on production needs and finished product requirements.

Common gypsum powder grinding mills include Raymond mills, ultrafine mills, and vertical roller mills:

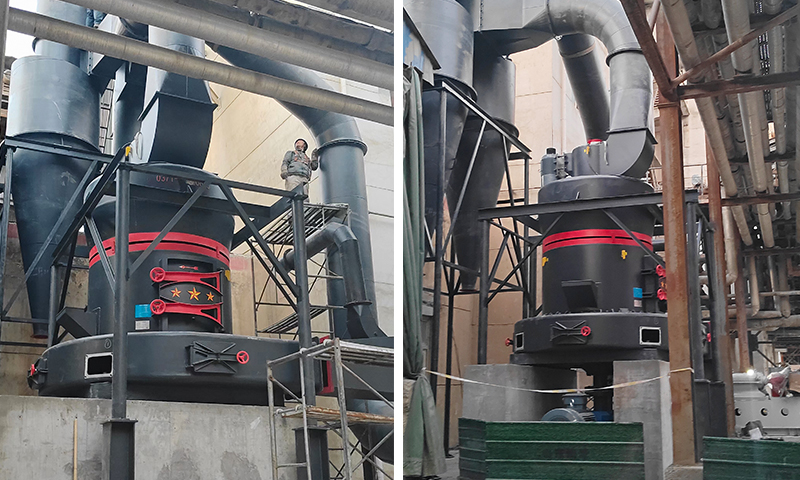

1. Raymond mill Get the Latest Price

Raymond mill is the traditional equipment for grinding gypsum, suitable for small and medium-sized enterprises. The grinding process is completed by squeezing and grinding with rollers and rings, making it ideal for processing gypsum with moisture content below 6%.

Why choose FTM Machinery's Raymond mill?

| Equipment | FTM Machinery Raymond Mill | Other Raymond Mills |

| Maximum output | 22 t/h | 11–15 t/h |

| Finished fineness | 80–325目(0.173 mm–0.033 mm) | 0.2 mm–0.05 mm |

| Investment cost | Low: combines drying and grinding, no need for extra dryer | Requires additional dryer |

| Part durability | Lifespan: grinding ring 8,000 hours, grinding roller 6,000 hours | Grinding roller and ring wear out easily |

| Environmental protection | 99% dust removal rate, low noise | No environmental protection devices |

| Energy consumption | Over 60% lower than traditional ball mills | Standard energy consumption |

2. Ultrafine mill Get the Latest Price

As an advanced grinding mill combining crushing, grading, and static pressure, the ultrafine mill excels in both fineness and environmental performance.

It is mainly used to produce ultrafine gypsum powder or micron-level particles, and is widely used in industries requiring high-fineness powders, such as chemicals, coatings, and plastics.

Specifications:

- Input size: <40 mm

- Output capacity: 0.4–40 t/h

- Output fineness: 60–800 mesh (0.25 mm–0.015 mm)

The ultrafine mill is an upgraded version of the Raymond mill, with a more attractive appearance. It uses a cage-type classifier for low noise, low vibration, and excellent sealing.

Compared to the standard motor used in Raymond mills, the ultrafine mill is equipped with a variable-speed motor and an arc-shaped air duct design, reducing air resistance and increasing efficiency.

Benefits of the Ultrafine Mill:

- Superfine results: Achieves particle sizes beyond what other grinders can reach, tightly controlling gypsum particle size distribution and increasing surface area.

- Low maintenance costs: With segmented rollers and specially designed wear-resistant shovel heads, the replacement cost of wear parts is reduced by over 50%.

- High powder collection rate: Equipped with a larger cyclone powder collector and roller-linked pressure boosting technology, combined with an air-lock feeder, greatly improving powder collection rate.

- Low risk of contamination: Multi-level dust sealing ensures that gypsum powder is not contaminated by internal machine parts.

3. Vertical roller mill Get the Latest Price

The vertical roller mill, known for its high production efficiency and ability to integrate crushing, drying, grinding, grading, and conveying, has become the preferred equipment for large-scale gypsum powder production.

Key features of the vertical roller mill:

- Large feed size: Gypsum ≤55 mm can enter the system directly, eliminating secondary crushing and simplifying the process.

- High capacity: The production capacity can reach 420 t/h.

- Wide output range: Output fineness adjustable between 14 mesh and 2500 mesh.

The vertical roller mill also has strong drying capabilities, with a hot air furnace providing 450°C air to effectively dry materials with up to 15% moisture content. Additionally, it consumes 30%–50% less energy than traditional ball mills.

This machine features a dynamic classifier that removes fine powders in time, reducing over-grinding and making the material easier to calcine. Moreover, the vertical roller mill occupies about 50% of the space of a ball mill, with infrastructure investment only 70% of a ball mill system.

Customer case: 300 tons per day gypsum powder production (Thailand)

Thailand is rich in gypsum mineral resources. As the construction market in Southeast Asia rapidly expands, a leading gypsum producer in Thailand approached FTM Machinery for help in upgrading their equipment to increase gypsum powder production.

Goals:

- Achieve a daily output of 300 tons of high-quality gypsum powder.

- Reduce production costs and improve energy efficiency.

- Ensure product quality while minimizing environmental pollution.

Solution:

FTM Machinery designed and installed a gypsum powder production line for the producer, including a high-efficiency PC 1000×800 hammer crusher, two 4525 Raymond mills, a vibrating screen, belt conveyors, a bag dust collector, an automatic packaging machine, and a centralized control system.

Project results:

- Production achieved: Successfully met the goal of producing 300 tons of gypsum powder per day.

- Cost reduction: Optimizing equipment configuration and process flow reduced overall production costs by 20%.

- Energy efficiency: Energy consumption decreased by 30% compared to traditional production lines.

- Environmental compliance: The production process fully complied with Thailand's environmental regulations, ensuring sustainable production.

Efficient gypsum grinding mills are crucial for ensuring high-quality and efficient gypsum processing. If you believe any of the applications we've discussed could benefit your manufacturing business or if you have any questions about gypsum mills, feel free to contact our team. Contact us