The rise of renewable energy has exposed a new challenge - energy storage.

Solar and wind energy, though inexpensive, are intermittent. To make the entire grid rely on renewable energy, a large amount of storage is needed to avoid blackouts.

It is at this moment that an extraordinary metal - vanadium, through vanadium battery technology, has shown its irreplaceable role in the field of sustainable energy.

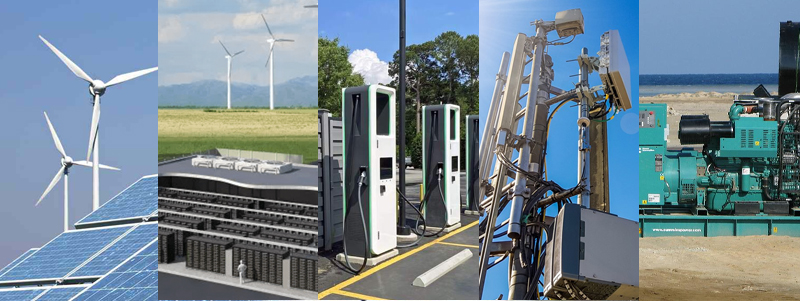

Its unique advantages make it applicable to solar and wind farms, grid energy storage systems, electric vehicle charging, solar panels, diesel generators, and communication base stations.

How does the vanadium battery work?

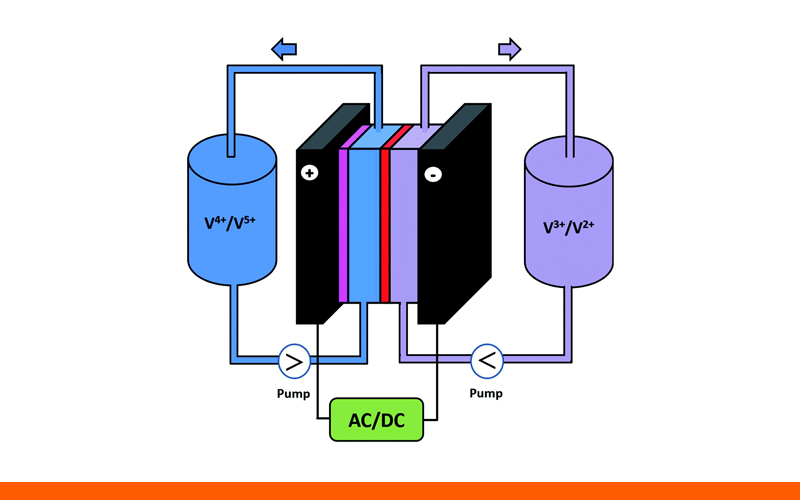

Our most common vanadium battery is the vanadium redox flow battery (VRFB).

It is important to know that batteries come in various types, such as those storing energy through physical force or chemical reactions. Vanadium redox flow battery belongs to the latter category.

What makes this battery unique is that it uses a metal called vanadium inside, which can also take on several different forms.

Its working principle, simply put, is to store and release electrical energy by utilizing the conversion of vanadium ions between different oxidation states.

How is the vanadium in the vanadium battery obtained?

There is a special liquid in the battery called electrolyte.

Its main component, vanadium pentoxide (V₂O₅), is of high purity, which establishes the excellent performance of the vanadium battery and demonstrates the high value of the vanadium.

Vanadium, a transition metal, is gray-white in color, with excellent ductility, corrosion resistance, and strength. It remains solid at room temperature, with a melting point of 1910°C and a boiling point of 3407°C.

The vanadium in vanadium batteries is extracted from vanadium ore.

Vanadium primarily exists in the form of vanadium titano-magnetite (the main source), vanadinite, uranium-vanadium ore, and descloizite. Trace amounts of vanadium are also found in some coal, petroleum, and stone coal.

FTM Machinery excels in efficiently crushing, grinding, and beneficiating vanadium ore, elevating them to vanadium concentrates.

The production steps of high-purity vanadium pentoxide you are interested in:

1 Initial crushing and screening: Employing specialized jaw crushers and cone crushers to gradually crush large vanadium titano-magnetite ores. Vibrating screens ensure the obtained ore reaches suitable processing fineness while effectively separating impurities.

2 Fine grinding: Further refining the ore through ball mills or rod mills until the particle size is below 3mm.

3 Magnetic separation: Utilizing weak magnetic separators in precisely controlled magnetic field environments to discard tailings and obtain coarse concentrates.

4 Multi-stage reprocessing: After two rounds of grinding and magnetic separation, each cycle further refines the purity and grade of the concentrates, gradually approaching the ideal state.

5 Deep concentration: Additional magnetic separation steps yield high-grade, high-recovery concentrates.

6 Blast furnace smelting: Feeding vanadium titano-magnetite concentrates into blast furnaces for co-smelting with coke or coal to transfer vanadium elements into molten iron.

7 Vanadium slag blowing: Subjecting molten iron to blowing in converters to obtain vanadium-rich oxides and iron oxides in the form of vanadium slag and semi-steel after selective oxidation, which serves as vanadium extraction material.

8 Refinement and purification: Utilizing chemical processes such as leaching, precipitation, and solvent extraction to refine vanadium, ultimately yielding high-purity vanadium pentoxide.

What you also want to know:

Safer, more durable, more recyclable (compared to common batteries)

Currently, lithium-ion, lead-acid, nickel-metal hydride batteries, and supercapacitors are the most widely used products in energy storage solutions.

However, they also face some challenges:

- Limited reserves: Unable to meet all the demands for high-energy and high-power storage.

- Safety concerns: Potential risk of fire or explosion.

- Environmental impact: Use of toxic heavy metals, with limited recyclability.

- Decreasing efficiency: Energy storage degrades over time.

According to incomplete statistics, more than 70 energy storage safety accidents have occurred around the world since 2023, most of which were caused by lithium batteries.

In comparison, vanadium redox flow batteries have better characteristics.

- Safer: Flow battery electrolyte consists of an aqueous solution, eliminating the risk of thermal runaway seen in lithium-ion batteries, preventing combustion or explosion.

- Longer lifespan: It can withstand tens of thousands of charges and discharges and has a lifespan of more than 25 years, exceeding the traditional battery cycle.

- Flexible expansion: To increase the capacity, you only need to expand the electrolyte tank or increase the concentration; to increase the power, you need to increase the stack area.

- Recyclable: Vanadium ions in the electrolyte can be chemically converted back into usable forms after use.

Conclusion

Projected to dominate the energy storage market above 1MW capacity in the future, vanadium redox flow batteries owe their success to the critical mineral resource, vanadium.

FTM Machinery will continue to provide efficient crushing, grinding, and beneficiation services, offering robust support for the commercialization and scale-up application of vanadium redox flow battery technology.