In recent years, global gold prices have fluctuated significantly, with a notable upward trend in 2024. As of September 2024, the price of gold has risen to over $2,600 per ounce, compared to around $1,900 during the same period in 2023.

This more than 30% increase highlights the unique status of gold in the global market. In this context, African gold processing plants play an increasingly important role in the global supply chain.

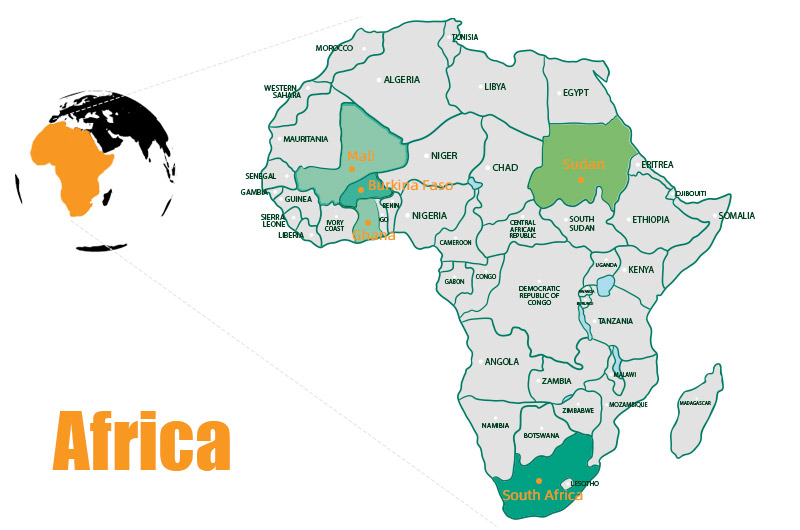

Africa – world’s largest regional gold producer

Major gold-producing countries in Africa include South Africa, Ghana, Mali, Burkina Faso, and Sudan.

According to data from Nasdaq, South Africa produced 100 metric tons of gold in 2023, ranking first in Africa and ninth globally. With 5,000 tons of gold reserves, South Africa remains among the top three globally.

South Africa's Witwatersrand Basin is one of the world's top gold resources, home to the world's largest gold mine, South Deep, and the deepest, Mponeng Mine.

Ghana, often called the "Gold Coast," relies heavily on gold, with the mineral accounting for around 95% of the country's mining revenue.

Burkina Faso's gold industry has seen rapid growth in recent years. At the end of 2023, the country began constructing its first gold refinery, with an annual refining capacity of 150 tons, marking a major milestone in its mining infrastructure development.

Gold processing plants in Africa

Do you know which types of gold ores are most popular in Africa? Whether it's alluvial gold, placer gold, rock gold, sulfide gold ore, or oxide gold ore, they can all be processed into valuable gold bars or jewelry.

Today, local gold processing is becoming a priority for many African mining countries. For a long time, these countries exported raw materials to overseas refineries for processing, but now they are working to improve their own processing capabilities.

So, how can we obtain more gold at a lower cost?

Case 1: South Africa 800 tpd low-grade rock gold processing plant

This South African gold processing plant mainly processes complex sulfide gold ore, with a capacity of 800 t/d and a maximum feed size of 400 mm.

The plant uses flotation to extract gold, with an overall recovery rate of about 75%. The main equipment is as follows:

| Equipment type | Equipment model | Quantity |

| Jaw crusher | PE-600×900 | 1 |

| Cone crusher | SC250 | 1 |

| Overflow ball mill | Φ2700×4500 | 2 |

| Flotation machine | SF-8 | 6 |

1. Two-stage crushing

Large gold ore first enters the jaw crusher for primary crushing, then goes through the cone crusher for secondary crushing, separating out gangue minerals. The crushed gold ore is screened by a vibrating screen.

2. Grinding

The screened gold ore is sent to the overflow ball mill for grinding, achieving a fineness of over 180 mesh to ensure good flotation results.

3. Classification

The ground gold ore is classified using a spiral classifier, washing and desliming. The ore that meets the size requirements goes to the flotation machine, while coarse material returns to the ball mill for further grinding.

4. Flotation

The ore enters the flotation machine, where flotation reagents are added and mixed evenly. Useful gold minerals form bubbles and float to the top of the flotation machine, resulting in a slurry rich in gold minerals. Unused minerals settle to the bottom as tailings.

The reagents used in flotation play a crucial role in gold recovery, including:

- Collector: The collector helps gold minerals attach to bubbles for flotation separation.

- Frother: The frother promotes foam formation and maintains stability, ensuring mineral particles attach to bubbles.

- Modifier: Used to suppress associated sulfide minerals like pyrite and galena, selectively floating out gold.

- Regulator: Adjusts pH and other chemical conditions to optimize flotation results.

A common reagent combination for sulfide gold ore is: collectors use xanthate, frothers use pine oil, modifiers include sodium cyanide and zinc sulfate, and regulators use lime.

Note: Generally, collectors should be added before frothers to preferentially attach to the desired minerals.

5. Concentration and filtration

The flotation slurry needs to be concentrated in the concentrator to remove most of the water, turning the gold concentrate into a thicker slurry. Then, further dewatering occurs through a filter to obtain dry gold concentrate.

Flotation is suitable for complex ores that cannot be processed by gravity methods. The recovery rate of gold concentrates is high, but the equipment costs are relatively large. Reach out for details!

Case 2: Nigeria 50 tph alluvial and placer gold processing plant

This gold processing plant in Nigeria mainly handles alluvial gold and placer gold ore that contains clay. The ore is mostly in granule form, with a production capacity of 50 t/h and a feed size of 0–200 mm, where the placer gold granule size is 0–3 mm.

The plant uses gravity separation for processing, and the main equipment includes a rotary screen, jig, and shaking table.

Gold processing steps:1. Wet crushing and washing

The raw gold ore is fed evenly into the trommel screen using a vibrating feeder. High-pressure water is used to wash the ore, breaking down clay and mud while cleaning it thoroughly. Large ore pieces are discharged from the back of the screen, while smaller pieces go to the jig.

2. Beneficiation

The jig processes the coarse and fine ore separately using gravity separation. The coarse ore is discarded, while the fine ore is further selected, with the jig's tailings becoming useful gold concentrates.

3. Gold extraction

The ore selected by the jig is then processed on the shaking table for further gold extraction. The shaker uses the difference in settling of different-sized ores under gravity to obtain high-grade gold concentrates. Reach out for details!

- The rotary screen is ideal for processing alluvial gold, placer gold, and river mud gold. It efficiently and quickly washes the ore, making it suitable for large-scale processing, easy to operate, and low cost.

- The jig, as a gravity separation device, effectively separates gold from other gangue minerals due to the high density of gold (19.3 g/cm³), recovering most useful minerals with a high recovery rate.

- The shaking table is more efficient than other fine-grained gravity separation devices. It can separate different sizes of coarse sand (2–0.5 mm), fine sand (0.5–0.074 mm), and slime (–0.074 mm). It processes a large amount of gold ore at once, resulting in high-grade gold concentrates.

Case 3: Tanzania 10 tph rock gold processing plant

The processing plant in Tanzania handles rock gold, which is an oxide gold ore. The ore is fine-grained and hard, with a production capacity of 10 t/h and a feed size of 0–125 mm.

This gold extraction plant uses gravity separation, achieving a high recovery rate of free gold at 97%. Compared to flotation plants, this plant is more cost-effective and provides quicker returns, making it popular among African gold miners.

Gold processing steps:- 1 Two-stage crushing: Large gold ore is first crushed using a jaw crusher for primary crushing, then further crushed by a hammer crusher.

- 2 Grinding: The crushed ore enters a ball mill and is ground into a fine powder to completely release the free gold.

- 3 Gold extraction: The ground ore is processed on a shaking table for gravity recovery, resulting in high-grade gold concentrates. Reach out for details!

In addition, popular gold extraction methods include cyanide gold extraction, carbon-in-pulp (CIP) gold extraction, and resin-in-pulp (RIP) gold extraction. All of these methods are based on surface gold ore.

- Gold cyanide process: The gold ore is contacted with a cyanide solution, separating solids from the clear liquid; gold is recovered from the zinc solution using precipitation.

- Carbon pulp gold extraction process (CIP/CIL): This method uses activated carbon to recover gold. Activated coconut shell carbon is added to the cyanide slurry to adsorb dissolved gold, which is then extracted.

- Resin pulp gold extraction process: Gold can also be extracted from the slurry using ion-exchange resin. In this process, gold adsorbs onto solid spherical polystyrene resin beads. SGS is a well-known manufacturer of resin-in-pulp gold extraction, recognized by Forbes as one of the best multinational companies.

FTM Machinery's manufacturing capabilities

FTM Machinery offers customized design, manufacturing, and supply of gold processing equipment for new and existing projects, working closely with clients to ensure faster and more efficient gold recovery. Need help? Contact us today!

How our manufacturing process benefits your gold processing plant:

- Enhanced gold recovery rates

- Minimized operational downtime

- Increased productivity

- High standards of quality and safety

- Continuous innovation and improvement

FAQs

1. What is a gold processing plant?

A gold processing plant is a facility specifically designed to extract gold from ores. It uses physical, chemical, and other processes to remove gold from raw ores. Common methods include gravity separation, flotation, and heap leaching.

2. What should be considered when setting up a gold processing plant?

- Location: The plant should be as close to the mining area as possible, ensuring easy access to transportation, energy, water, and labor to reduce costs.

- Environmental regulations: Follow local mining laws and properly handle the discharge of toxic substances like cyanide.

- Technology: Choose the right gold extraction process based on the type of ore, such as gravity separation, flotation, or heap leaching.

- Funding: Ensure enough startup and operating capital, and consider financing options.

3. Top 10 largest gold mines by production in 2023

| Mine | Location |

| Muruntau Mine | Uzbekistan |

| Carlin Mine | USA |

| Olimpiada Mine | Russia |

| Cortez Mine | USA |

| Grasberg Block Cave Mine | Indonesia |

| Boddington Mine | Australia |

| Lihir Mine | Papua New Guinea |

| Pueblo Viejo Mine | Dominican Republic |

| Kibali Mine | Democratic Republic of the Congo |

| Loulo-Gounkoto Mine | Mali |