What is a gold processing plant?

Many gold mining projects underperform not because of low-grade ore, but because of an inefficient processing flow sheet.

A poorly selected recovery method can easily result in 30–40% gold losses, directly hurting cash flow and return on investment.

A gold processing plant (gold ore beneficiation line) is a complete system that transforms raw gold ore into pure gold bullion. A typical gold processing plant includes:

- Crushing & screening

- Grinding & classification

- Gold beneficiation (gravity, flotation, CIL, CIP)

- Thickening & dewatering

- Smelting & gold bar production

A well-designed gold extraction plant can achieve 90–98% total gold recovery with low energy consumption and stable long-term operation.

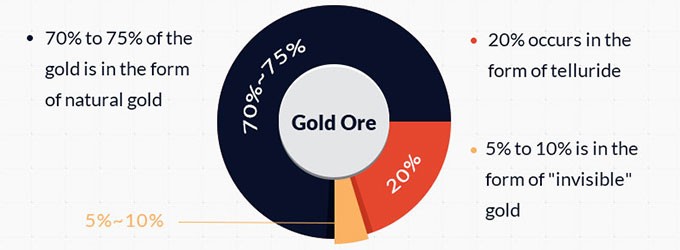

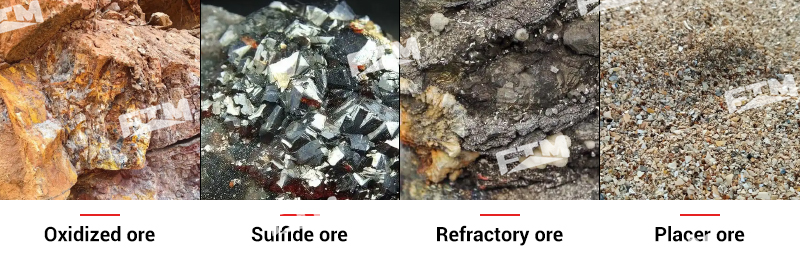

Gold ore types and suitable beneficiation methods

The most critical step in designing a high-recovery gold plant is understanding your ore — not choosing equipment. A professional mineralogy test is mandatory before finalizing any process flow.

Different types of gold ore correspond to vastly different beneficiation methods:

| Gold ore type | Characteristics | Recommended gold extraction process |

| Oxidized ore | Soft, permeable, free-milling | CIP / CIL gold plant |

| Sulfide ore | Fine gold locked in sulfides | Gold flotation + cyanidation |

| Refractory ore | Gold locked in arsenopyrite or pyrite | Roasting / pressure oxidation + CIL |

| Placer ore | Coarse free gold | Gravity separation + CIL |

Selecting the wrong process can cap recovery below 50%, while the correct flow sheet can push recovery to 85–95% or higher.

Three dominant gold recovery methods

The recovery stage determines both final gold recovery and operating cost.

- Gravity separation: Ideal for coarse/free gold; low cost, no chemicals.

- Flotation: Best for fine or sulfide gold; enrichment ratio up to 100×.

- Cyanide leaching: Essential for ultra-fine or refractory gold ores when maximum recovery is required.

One correct process decision can define years of profitability. Contact our engineers to get a customized process solution tailored to your specific ore.

Key stages in gold processing

A gold mining production line is an industrial process that involves crushing, classification, concentrating, gold recovery, dewatering, and final gold product production.

Stage 1: Crushing (Preparation)

The goal is to reduce the size of the raw gold ore to a feed size suitable for the grinding circuit, maximizing the efficiency of the next stage.

- Primary crushing: Jaw Crusher (handles massive blocks).

- Secondary/tertiary crushing: Cone Crusher (produces a fine, uniform output).

- On-site flexibility: The use of Mobile Crushing Plants allow contractors to process gold ore directly at the mine face.

Stage 2: Grinding & Classification

This is the most energy-intensive stage, where the gold ore is milled to a fine particle size, physically "liberating" the gold from the surrounding rock matrix.

- Grinding equipment: Ball Mills or Rod Mills. 70–90% passes through a 200–mesh sieve.

- Classification equipment: Spiral Classifiers are used to return oversized particles back to the grinding mill, ensuring that only material fine enough for extraction proceeds.

Fine grinding is essential—studies show that every 5% improvement in liberation can increase final gold recovery by 1–3%.

Stage 3: Gold Beneficiation (Recovery Methods)

This is the core of gold ore beneficiation. The process selection depends on mineralogy, particle size, and gold occurrence.

A. Gold gravity separation

Gravity separation is suitable for coarse free gold and placer gold deposits. It is often used as a pre-concentration step before CIP/CIL. Recovery of coarse gold can reach 70–90%.

- Equipment: Shaking Tables and Spiral Chutes.

- Advantage: Low operating costs and no chemical consumption, making it an excellent pre-concentration step.

B. Gold flotation

Flotation is used for fine-grained gold, sulfide-associated gold, or ores that are difficult to leach. It effectively concentrates gold, silver, and copper into high-grade concentrates.

- Equipment: Flotation Cells and Agitation Tanks.

- Advantages: Enrichment ratio of 50–100×, significantly reduced cyanide consumption, and total recovery increased to 85–95%.

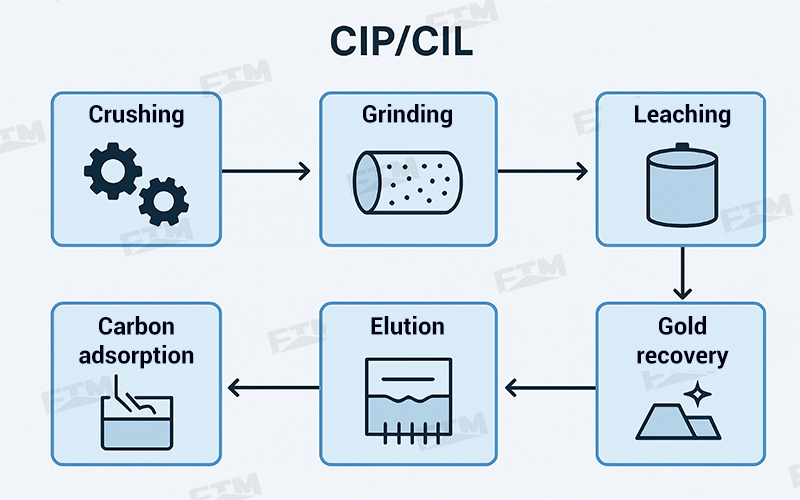

C. Cyanide leaching

Cyanidation is suitable for oxidized gold ores, ultra-fine particles, low-grade ores, and refractory ores, especially when high recovery is required.

Common processes:

- CIL (Carbon in Leach): Leaching (dissolving the gold) and adsorption (adsorbing gold onto carbon) occur simultaneously.

- CIP (Carbon in Pulp): Leaching occurs first, followed by gold adsorption.

- Heap leaching: Used for very low-grade, porous ore.

Stage 4: Thickening and Dewatering

Dewatering recovers valuable process water and handles tailings.

- Thickening: Thickening is carried out after gold recovery to allow solids to settle.

- Tailings dewatering: The final process of removing water from the residual material (tailings) to minimize environmental risk and maximize water recirculation.

- Equipment: Thickeners (for concentration) and Filter Presses (for fine tailings dewatering).

Stages 5 & 6: Refining (Elution, Electrowinning & Smelting)

These are the final steps that yield the pure gold product:

- Elution & electrowinning: The gold is stripped (eluted) from the loaded activated carbon using a specialized solution, and then recovered via electrolysis, yielding concentrated gold sludge (gold mud).

- Smelting: The gold mud is melted in a high-temperature smelting furnace and cast into the final Dore Bars (gold ingots).

Case studies of gold ore processing plants

Case 1: Oxidized gold CIP beneficiation plant (1,000 TPD)

A medium-scale gold mine in West Africa processes low-grade oxidized gold ore with an average grade of 1.5 g/t. We designed an efficient CIP (Carbon in Pulp) processing flowsheet, integrating high-pressure cone crushing, ball milling, and a high-efficiency thickening system.

The gold ore plant has achieved a stable gold recovery rate of 95.5%, significantly improving the mine's cash flow and overall project economics.

This solution is especially suitable for small to medium-sized gold mines seeking fast payback.

Case 2: Achieving 97% recovery from complex sulfide ore (150 TPD)

This mine previously relied on direct leaching, with gold recovery remaining below 60%. We implemented a combined process of "flotation pre-concentration + CIL leaching of concentrate":

- Flotation concentration ratio: 80:1

- Cyanidation applied only to a small volume of high-grade concentrate

As a result, the overall gold recovery increased to 97.2%, while reagent consumption was significantly reduced. This is a typical high-recovery solution for complex sulfide gold ores.

If you are planning a similar project, we can design a customized gold processing plant based on your ore type and budget.

Cost of building a gold processing plant

The capital investment required to build a gold processing plant mainly depends on the plant capacity, ore type, process complexity, and local energy and labor costs.

| Gold ore plant size | Estimated investment cost |

| 30–50 TPD small plant | $150,000 – $500,000 |

| 100–300 TPD medium | $0.5M – $2M |

| 500–2000 TPD large | $3M – $12M |

Operating costs typically range from $20 to $50 per ton, depending on the gold ore grade. The investment payback period for most gold mining operations is 8–18 months.

Conclusion

Even a 1% increase in gold recovery rate is often enough to offset the investment cost of high-efficiency equipment. Choosing the wrong process, however, can result in years of lost revenue.

We offer:

- Professional mineral testing

- Customized flow sheet design

- Free technical consultation at the project planning stage

Ensure your process is correct before purchasing any equipment. Send us your ore sample or project details now to get a free customized solution. Contact us